Welding Process Type | Welding Process Name | Advantage | Material | Industry |

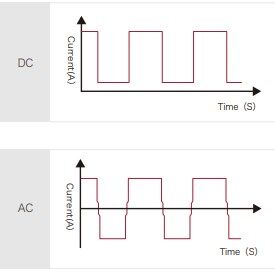

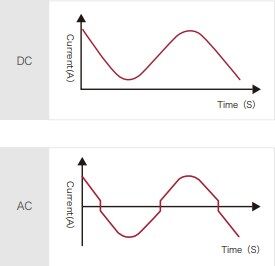

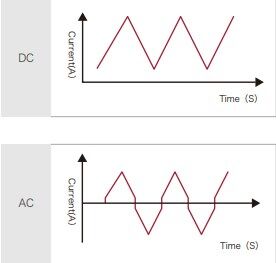

| DC TIG Welding | DC TIG Welding | Stable arc, high adaptability for the gap, easier for one-sided welding and double-sided forming | Carbon steel, stainless steel, titanium alloy, etc | Petrochemical, pressure pipeline&vessel backing weld, etc. |

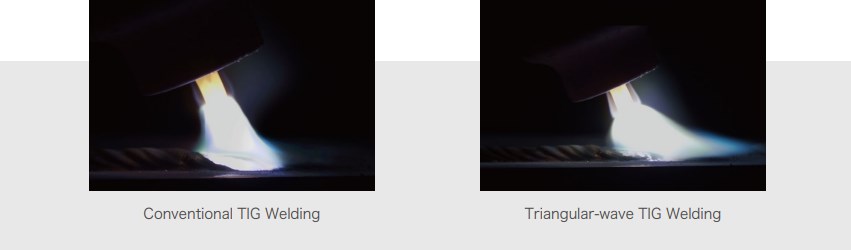

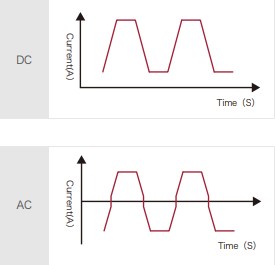

| DC PULSE TIG Welding | DC-Pulse TIG Welding | Low heat input, beautiful fish-scale shape is available, pulse frequency up to 3000Hz | Carbon steel, stainless steel, titanium alloy, etc | Sheet metal and welding occasions with requirements for heat input and weld form, etc. |

| AC TIG Welding | AC TIG Welding | Stable arc, AC frequency up to 300Hz | Aluminum, aluminum alloy, magnesium, etc. | Aluminum alloy pipelines, bicycle frame welding with high appearance requirements, etc. |

| AC TIG Pulse Welding | Double Pulse AC TIG Welding | Low heat input, clear fish-scale welding shape | Aluminum, aluminum alloy, magnesium, etc. | Aluminum alloy thin-plate and welding occasions requiring heat input and weld forming, etc. |

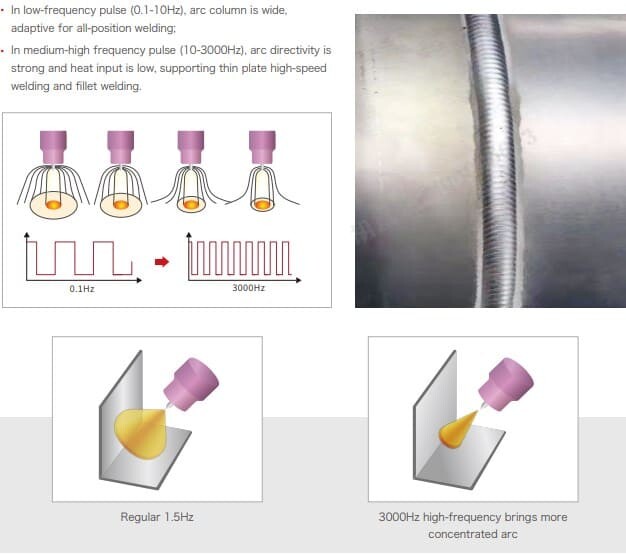

| AC DC TIG Pulse Welding | Double-pulse AC DC TIG Welding | Deeper penetration and less tungsten loss | Aluminum alloy, aluminum, magnesium etc. | Aluminum alloy medium and thick plates, welding occasions requiring depth of penetration, etc. |

| MMA | MMA | Easy arc start, non-stick with rod, softer arc&less spatter, and beautiful weld shape | Carbon steel, alloy steel, stainless steel, etc. | Boiler, pressure vessel, petrochemical industry, pressure pipeline, outdoor construction, etc. |