Welding is a critical process in various industries, from construction and automotive to shipbuilding and aerospace. Understanding the different welding positions and joint types is essential for producing high-quality welds. In this blog, we will explore the fundamental welding positions—1G, 2G, 3G, 4G, 5G, and 6G—and their respective joint types, providing you with the knowledge to enhance your welding skills and project outcomes.

I. What Are Welding Positions?

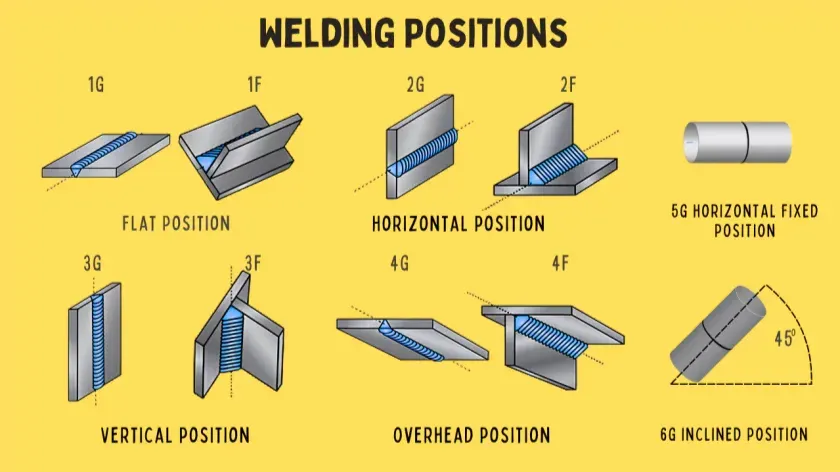

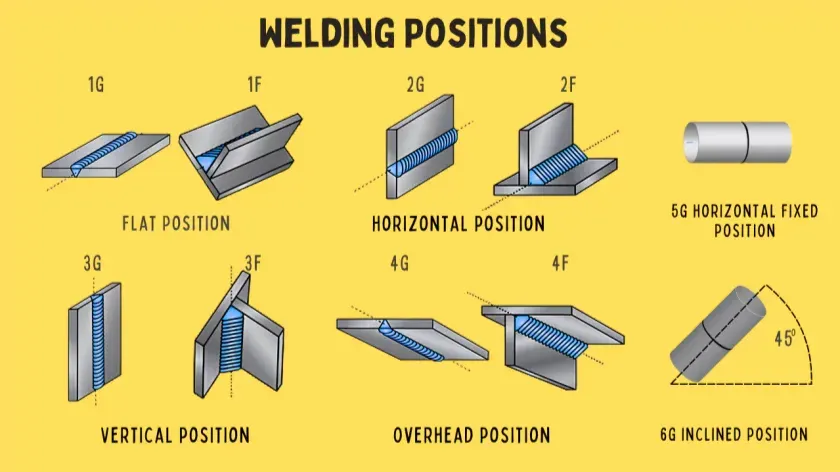

Welding positions refer to the orientation of the weld and the workpiece in relation to the welder. These positions are standardized by the American Welding Society (AWS) and are crucial for certification and practical applications. Each position has unique challenges and requires specific techniques to achieve optimal results.

II. Understanding the Basic Welding Positions

1) 1G (Flat Position):

Description: The 1G position, also known as the flat position, is the simplest and most common welding position. The workpiece is placed horizontally, and the weld is performed on the upper side.

Application: This position is ideal for beginners due to its simplicity. It's commonly used in welding flat plates, pipelines, and simple structures.

Joint Types: Butt joints and fillet joints are commonly used in the 1G position.

.png)

2) 2G (Horizontal Position for Butt Welds):

Description: In the 2G position, the workpiece is vertical, and the weld is performed horizontally along the joint.

Application: This position is frequently used in pipeline welding and structural applications where horizontal welds are necessary.

Joint Types: T-joints and butt joints are typical for the 2G position.

.png)

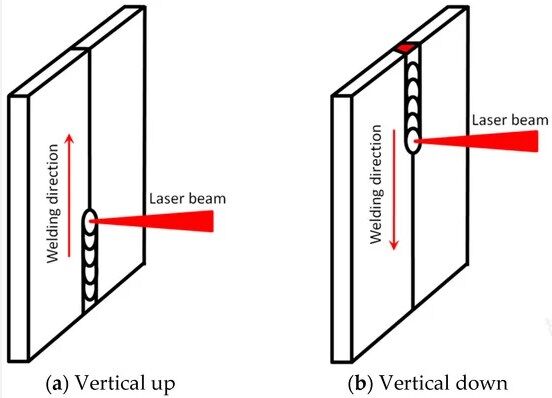

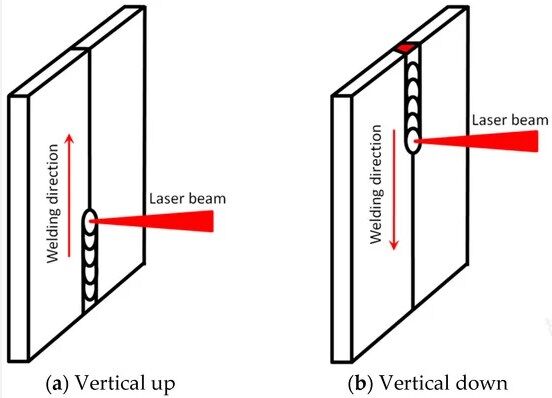

3) 3G (Vertical Position)

Description: The 3G position involves welding in a vertical orientation. The weld can be performed either from bottom to top (uphill) or top to bottom (downhill).

Application: This position is essential for structural welding, especially in construction projects where vertical seams are common. Learn How to Weld Vertical: Tips and Techniques for Various Processes.

Joint Types: Butt joints and lap joints are commonly used in the 3G position.

.png)

4) 4G (Overhead Position)

Description: The 4G position requires welding from underneath the workpiece, which is positioned overhead.

Application: This challenging position is often encountered in repair work and in situations where the workpiece cannot be moved.

Joint Types: Overhead welding typically involves butt joints.

.png)

5) 5G (Horizontal Fixed Position)

Description: The 5G position is specifically for pipe welding. The pipe remains stationary, and the welder must perform the weld around the pipe's circumference.

Application: This position is critical in pipeline construction and maintenance, where pipes cannot be rotated.

Joint Types: Circumferential welds (girth welds) are typical in the 5G position.

6) 6G (Inclined Position)

Description: The 6G position is one of the most difficult welding positions. The pipe is inclined at a 45-degree angle, and the welder must weld around the pipe's circumference.

Application: This position is used for certifying welders due to its complexity. It's common in high-pressure and critical welding applications, such as oil and gas pipelines.

Joint Types: Circumferential welds are performed in the 6G position.

III. Why Are These Positions Important?

Understanding and mastering these welding positions is crucial for several reasons:

1) Standardization for certification and qualification

Welding codes and standards (ASME, AWS, API, ISO, etc.) use these position definitions to set qualification tests for welders and procedures. A welder qualified in a given position demonstrates they can produce sound welds under the specific orientation and constraints of that position.

Example: The 6G pipe test is widely used as a comprehensive qualification because it covers multiple positions in a single test.

2) Safety and reliability of welded structures

Different positions create different challenges for penetration, fusion, slag inclusion, porosity, and bead shape. Standardizing positions ensures welders are tested and procedures validated against the conditions they will encounter in service, reducing the risk of weld failure.

Proper qualification reduces the likelihood of structural failure, leaks, or costly rework.

3) Process control and procedure development

Welding procedure specifications (WPS) must define acceptable parameters for each position (e.g., current, voltage, travel speed, filler metal, preheat). Positions influence heat input, travel angle, and droplet transfer behavior, so procedures differ by position to achieve consistent quality.

Position-specific procedure qualification records (PQRs) provide data proving that a given WPS produces welds that meet mechanical and nondestructive test requirements.

4) Skill assessment and training

The positions map directly to skill progression: beginners usually start in 1G/flat welding and advance through 2G/3G to 4G/5G/6G as proficiency grows. Training programs use these positions to structure learning and testing.

Employers and certifying bodies use position endorsements on welder qualifications to assign appropriate tasks.

5) Real-world constraints and practicality

Many field situations require welding in fixed or awkward orientations (e.g., pipelines, pressure vessels, structural members). Knowing which position a job requires helps plan resources, choose appropriate electrodes/fillers, and anticipate challenges (e.g., need for back gouging, tack welds, or fixtures).

Position classification guides equipment choice: e.g., whether you can rotate the workpiece, use mechanized welding, or must rely on manual skill.

6) Quality, inspection, and acceptance criteria

Inspection criteria and acceptance levels (visual, radiographic, ultrasonic) often reference the welding position because defect types and typical locations vary by orientation. Position-based testing helps ensure acceptance criteria are realistic and relevant.

Some positions may require more stringent NDT due to difficulty controlling defects (e.g., overhead and vertical positions).

IV. FAQs of Common Welding Positions & Joint Types

Q1: What do welding positions mean?

Welding positions define how a workpiece is placed and the angle at which the weld is performed. They are standardized to ensure consistency and skill qualification across different applications.

Q2: What do the letters “G” and “F” represent?

G (Groove Weld): Welding between two edges with a groove.

F (Fillet Weld): Welding at an angle, like in T- or lap joints.

Q3: What are the common groove welding positions?

1G: Flat position — the easiest and most common.

2G: Horizontal position — weld runs along a vertical plate.

3G: Vertical position — weld moves upward or downward.

4G: Overhead position — weld performed from below the joint.

5G: Horizontal Fixed Position, horizontal axis — no pipe rotation.

6G: Inclined Position — tests all-position skill, often used for welder qualification.

Q4: What are the main joint types in welding?

Butt joint – two plates in the same plane.

Lap joint – overlapping plates.

T-joint – one plate perpendicular to another.

Corner joint – plates meet at a corner.

Edge joint – plates joined at the edges.

Q5: Which welding position is the most difficult?

The 6G position is considered the most challenging since the welder must work in multiple orientations—flat, horizontal, vertical, and overhead—on a fixed pipe.

V. Conclusion

Mastering the various welding positions—1G, 2G, 3G, 4G, 5G, and 6G—is essential for any welder looking to advance their skills and career. Each position presents unique challenges and requires specific techniques to ensure high-quality welds. At Megmeet Welding Technology, we provide the tools and knowledge you need to excel in these welding positions, ensuring your projects are completed with precision and excellence.

Related articles:

1. 5 Essential Weld Joint Types & Techniques for Superior Results

2. What are the 4 Basic Welding Positions and How to Choose the Right One?

3. How welding defects (pores, undercuts) affect weld joint?

4. Welding Joint Types: Butt, Lap, Tee, Edge Joints & More.

5. Pipeline Vertical Welding Methods Basics and Precautions

.png)

.png)

.png)

.png)