If you have ever spent time in a professional fabrication shop or even a well-equipped home garage, you have likely noticed that MIG welding doesn't always sound the same. One minute you might hear a crisp "crackling bacon" sound, and the next, a smooth, quiet hiss. These sounds aren't just background noise; they are the audible signatures of different MIG welding transfer modes.

Understanding the differences between short arc (short circuit) and spray transfer is one of the most important steps in moving from a beginner to a pro. Choosing the wrong mode can lead to weak joints, excessive cleaning time, or even burning holes through your workpiece. This guide will break down the mechanics, parameters, and best applications for each mode to help you optimize your welding projects.

I. What Are MIG Welding Transfer Modes?

In Gas Metal Arc Welding (GMAW), commonly known as MIG, "transfer mode" refers to how the molten metal travels from the end of your welding wire into the weld puddle. The mode is determined by your machine settings—specifically the voltage and wire feed speed (amperage)—and the type of shielding gas you are using.

There are four primary modes:

Short Circuit (Short Arc): Low energy, ideal for thin materials.

Globular Transfer: Medium energy, often considered the "messy" middle ground.

Spray Transfer: High energy, extremely productive for thick sections.

Pulsed Spray: Advanced digital control that offers the benefits of spray at lower heat.

While all MIG welding uses the same basic equipment, the way the arc behaves determines the strength, appearance, and speed of the weld.

II. Short Arc (Short Circuit) Transfer Explained

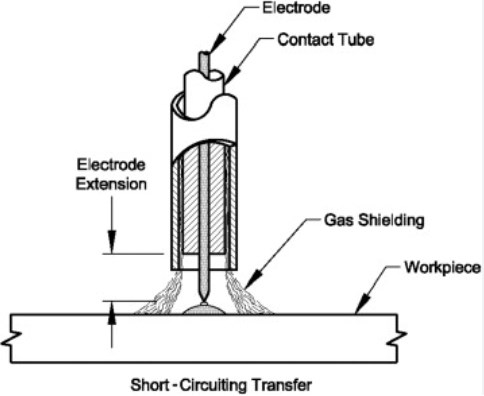

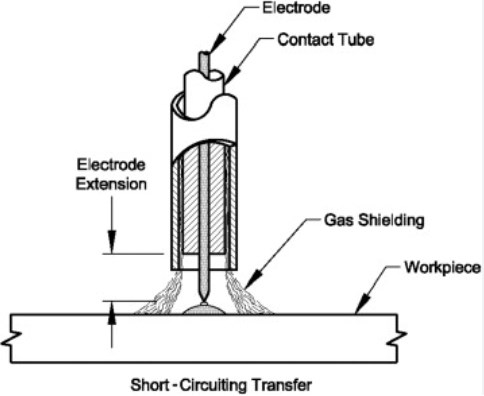

Short circuit transfer is the most common mode used by hobbyists and light fabrication shops. In this process, the welding wire actually touches the base metal, creating a deliberate electrical short circuit.

1) How it Works

When the wire touches the puddle, the electrical current spikes instantly. This surge in power causes the tip of the wire to melt and "pinch off," depositing a small droplet of metal into the joint. The arc then re-ignites briefly before the wire hits the puddle again. This cycle happens incredibly fast—between 20 and 200 times per second.

2) Why We Use Short Arc?

Low Heat Input: Because the arc isn't "on" constantly, it generates less heat. This makes it the perfect choice for thin sheet metal, like auto body panels, to prevent warping or burn-through.

All-Position Welding: The weld puddle is small and freezes quickly. This allows you to weld overhead, vertically up, or horizontally without the molten metal dripping out of the joint.

Forgiveness: It is generally easier to learn and control than high-energy modes.

3) The Downsides

The primary limitation is penetration. Short arc is generally recommended for metals up to 1/4 inch (6mm) or 3/8 inch at the absolute maximum. On thicker materials, it can lead to "cold lap" or lack of fusion, where the weld metal sits on top of the base metal without actually bonding to it.

III. Spray Transfer: The Heavy Hitter

Spray transfer is a high-productivity mode used in heavy industrial manufacturing. Instead of the wire touching the puddle, the metal is projected across the arc in a fine mist of tiny droplets.

1) How it Works

Spray transfer occurs when the voltage and amperage are high enough to overcome the surface tension of the molten wire. It looks like a steady stream or "needle" of metal being sprayed into the joint, much like a pressure washer. This requires a specific shielding gas mix—usually 80% Argon or higher.

2) Why We Use Spray Transfer?

Extreme Productivity: It offers much higher deposition rates than short arc, meaning you can lay down more metal in less time.

Deep Penetration: The intense heat ensures the weld fuses deeply into thick steel plates, providing superior structural strength.

Zero Spatter: When tuned correctly, spray transfer is nearly spatter-free, which almost eliminates post-weld grinding and cleanup.

3) The Downsides

Position Restrictions: The weld puddle in spray transfer is very large and fluid. Because of gravity, it is almost impossible to use for vertical or overhead welding—it is strictly for flat and horizontal positions.

Heat Issues: It generates massive amounts of heat, which will instantly blow a hole through thin materials.

IV. Comparison at a Glance: Short Arc vs Spray

| Feature | Short Arc (Short Circuit) | Spray Transfer |

| Common Sound | Rapid crackling/sizzling | Low hissing/whooshing |

| Typical Voltage | 14V – 24V | 25V – 35V+ |

| Shielding Gas | 75% Ar / 25% CO2 or 100% CO2 | 80%+ Argon / Balance CO2 |

| Metal Thickness | Thinnest sheets to 1/4" | 1/8" and thicker |

| Welding Position | All positions | Flat and Horizontal only |

| Spatter Level | Low to Moderate | Very Low to None |

| Deposition Rate | Low | High |

V. Understanding the "Messy Middle": Globular Transfer

If you find yourself with an arc that is loud, unstable, and throwing huge balls of metal (spatter) everywhere, you are likely stuck in Globular Transfer.

Globular transfer happens when you have too much voltage for short arc, but not enough to reach a true spray. Large, irregular globs of metal form on the end of the wire and fall into the puddle under the influence of gravity. While it has good penetration, most professional welders avoid it because of the extreme cleanup required and the risk of poor bead appearance.

VI. Shielding Gas and Parameter Requirements

The mode you achieve is largely a result of your gas selection and machine settings. You cannot "force" a spray transfer if your gas doesn't support it.

1) Gas Mix for Short Arc

The gold standard for short arc on mild steel is C25 (75% Argon / 25% CO2). The CO2 helps with penetration and arc stability at low voltages. You can also use 100% CO2, which is even cheaper and provides deeper penetration, though it produces slightly more spatter.

2) Gas Mix for Spray Transfer

To enter spray mode, you need high Argon content to keep the arc column stable. Most experts recommend a mix of 90% Argon / 10% CO2 or 98% Argon / 2% CO2. If your gas contains more than 15-20% CO2, the transition to spray becomes physically impossible regardless of how high you turn up the voltage.

3) Parameter Cheat Sheet

For Short Arc (1/8" Steel): Try roughly 18-19 Volts and a wire feed speed appropriate for.030" or.035" wire (often 200-250 IPM).

For Spray Transfer (1/4" Steel): You will likely need at least 25-27 Volts and significantly higher wire feed speeds.

VII. Troubleshooting Transfer Mode Issues

If your weld doesn't look or sound right, check these common fixes:

Too Much Spatter in Short Arc: Your voltage might be too high for your wire speed, or your metal might be dirty. Try turning the voltage down slightly or cleaning the mill scale off your steel.

Lack of Fusion in Short Arc: You might be "running too cold." If the bead is ropey and sitting on top of the metal, increase your voltage.

Porosity (Bubbles): This is usually a gas flow issue. Check for drafts or a clogged nozzle. Recommended flow for indoor MIG is typically 15-25 CFH.

Stubbing into the Metal: If the wire is pushing your hand back and not melting, your voltage is too low for the wire feed speed you've selected.

VIII. Why Modern Inverters Are Changing the Game

Older transformer-based machines were often "stuck" in whatever mode their limited settings allowed. Today, digital inverter technology has revolutionized how we manage these transfers. Advanced machines now offer Pulsed MIG, which essentially "toggles" the power between spray transfer and a lower background current. This allows you to get the clean, spatter-free results of spray welding while being able to weld in all positions and on thinner materials.

FAQs

Q1: What is the best transfer mode for a beginner?

Q2: Can I spray transfer with 100% CO2?

Q3: Why am I getting "pop-pop" sounds instead of a hiss?

Q4: Does wire diameter affect the transfer mode?

Q5: Is pulsed MIG better than spray transfer?

Related article:

1. Megmeet RDT (Retract Droplet Transfer) Cold Metal Transfer Zero-Spatter High-speed Servo Arc Welding Technology Makes Its Debut at the Exhibition

2. MIG Welding: The Basics for Mild Steel

3. Push or Pull Mig Welding: Which One to Choose?

4. The Ultimate Guide to MIG Short Circuit Welding Techniques

5. Guide to Pulsed MIG Welding in Manufacturing