In the daily rhythm of a busy fabrication shop, one sound is more recognizable than any other: the steady, crisp "sizzle" of a MIG welder. This sound, often compared to frying bacon, is the hallmark of MIG Short Circuit Welding—also known as Short Arc or Dip Transfer.

While there are many ways to move metal from a wire into a joint, short circuit transfer remains the most widely used technique in the industry. It is the go-to method for welding thin-gauge sheet metal, filling gaps in poorly fitted parts, and managing difficult out-of-position welds like vertical-up or overhead.

However, just because it is common doesn’t mean it is easy to master. If your settings are off, you’ll end up fighting a mountain of spatter or, worse, "cold lap"—a defect where the weld looks perfect on the surface but hasn't actually fused to the metal. This guide will walk you through the principles, parameter settings, and best practices to ensure your short circuit welds are high-quality, strong, and efficient.

I. What Exactly Is the MIG Short Circuit Process?

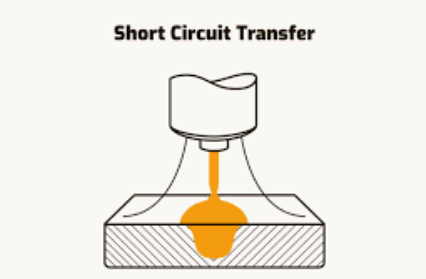

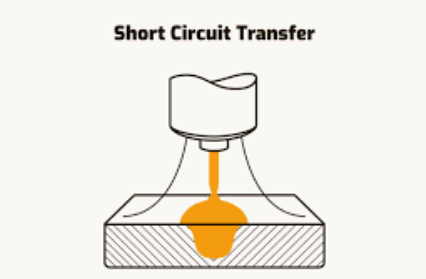

To understand how to improve your technique, you first need to know what is happening at the tip of your welding gun. Unlike "Spray Transfer," where the metal flies through the arc in tiny droplets, or "Pulsed MIG," which uses complex electronics to drop one bead at a time, Short Circuit Transfer is much more physical.

The process follows a specific cycle that happens 60 to 110 times every second:

The Touch: The welding wire feeds out of the gun until it physically touches the weld pool.

The Short: When the wire touches the grounded metal, it creates a short circuit. The voltage drops to near zero, and the amperage (current) sky-rockets.

The Pinch: This sudden burst of current heats the wire until the tip melts and "pinches" off into the weld pool.

The Re-ignition: As the wire detaches, an arc is briefly established, providing heat to keep the pool molten.

The Repeat: The wire continues to feed forward, touches the pool again, and the cycle starts over.

Because the arc actually "goes out" during the short-circuit phase, this is a low-heat process. This "cool" nature is exactly what makes it the king of thin materials and root passes.

II. How Do You Set the Correct Parameters?

Finding the "sweet spot" for short circuit welding requires balancing three main variables: Voltage, Wire Feed Speed (Amperage), and Stick-out. If you are welding mild steel, here is how to dial it in.

1. The 1-Amp Rule for Amperage

In MIG welding, you don't set the amperage directly; you set the Wire Feed Speed (WFS). A general rule of thumb is that for every 0.001 inch of material thickness, you need approximately 1 amp of power.

2. Matching Voltage to the Arc

Voltage is the "pressure" that controls the height and width of your bead. For short circuit welding using C25 shielding gas (75% Argon / 25% CO₂), the functional range is typically between 14 and 24 volts.

If the voltage is too low: The wire will "stub" into the metal, causing the gun to kick back and creating a tall, narrow bead with poor fusion.

If the voltage is too high: The arc becomes unstable and erratic. It may "burn back" toward the contact tip and produce excessive, fine spatter.

3. Maintaining the Correct Stick-out

"Stick-out" is the distance between the contact tip and the metal. For short circuit welding, you must keep this short—usually 1/4 to 3/8 inch. If your stick-out gets too long, the electrical resistance increases, which drops your amperage and leads to a "cold," spattery weld.

MIG Short Circuit Starting Parameters (Mild Steel - C25 Gas)

| Material Thickness | Wire Diameter | Voltage | Wire Feed Speed (IPM) |

| 24 Gauge (0.6mm) | .023 inch | 14 – 15 V | 130 – 160 |

| 1/8 inch (3.2mm) | .030 inch | 18 – 19 V | 220 – 260 |

| 1/8 inch (3.2mm) | .035 inch | 19 – 21 V | 240 – 300 |

| 3/16 inch (4.8mm) | .035 inch | 20 – 22 V | 300 – 360 |

III. Why Is Inductance the "Secret Sauce" of Short Arc?

If your machine has a knob labeled "Inductance," you have a powerful tool for controlling spatter. Inductance controls how fast the current rises when the wire shorts out against the metal.

Low Inductance (Hard Arc): The current rises very fast. This creates a high frequency of short circuits per second. The bead is narrower and freezes quickly. This is ideal for very thin sheet metal where you want to avoid blowing holes.

High Inductance (Soft Arc): The current rises more slowly. This creates a more fluid weld pool that "wets" into the edges (toes) of the weld beautifully. This is best for thicker materials or when you want a smooth, flat bead with almost zero spatter.

Adjusting inductance changes the sound of the arc. A low setting sounds sharp and crisp, while a high setting sounds smoother and more muffled.

IV. What Is the Best Shielding Gas for Short Circuit?

While you can run short circuit MIG with 100% CO₂, it isn't always the most productive choice.

75% Argon / 25% CO₂ (C25): This is the gold standard for general fabrication. The Argon provides a very stable arc and low spatter, while the CO₂ ensures good penetration. It makes for a much cleaner weld that requires less grinding afterward.

100% CO₂: This is the most cost-effective gas. It provides the deepest penetration, making it useful for thicker plates or cutting through light rust and mill scale. However, it produces significantly more spatter and a rougher bead.

V. Mastering Out-of-Position Techniques

One of the biggest advantages of short circuit welding is that the weld pool freezes quickly, allowing you to weld in positions where gravity would normally pull the metal out of the joint.

1. How to Weld Vertical-Up (3G)

For anything thicker than 1/4 inch, you should always weld Vertical-Up to ensure penetration.

Reduce Heat: Drop your voltage and wire speed by about 10-15% from your flat-position settings.

Technique: Use a Triangle or an Upside-Down V motion. Start at the bottom, move across the joint, then diagonally up into the center, and diagonally down to the other side.

Pause at the Edges: Briefly pause at the toes (sides) of the weld to allow the metal to tie in, then move quickly across the center to avoid a "hump" in the middle.

2. How to Weld Overhead (4G)

The key to overhead welding is a very short arc and fast travel speeds.

Shorten Stick-out: Keep your gun close to the work to maintain arc force.

Neutral Posture: Try to brace your arms against your body or a steady object to keep your hand steady.

Minimize Weaving: Keep your beads small. If the pool gets too large, gravity will cause it to drip.

VI. How to Prevent Common MIG Welding Defects?

Even experienced welders run into trouble. Here is how to troubleshoot the most common short circuit issues.

1. Cold Lap (Lack of Fusion)

This is the most dangerous defect because it often looks like a good weld. It happens when the molten filler metal rolls over the top of the base metal without actually melting into it.

Cause: Voltage too low, travel speed too slow, or dirty metal.

Solution: Increase your voltage, speed up your travel, and ensure the arc is always on the leading edge of the weld pool.

2. Porosity (Tiny Pinholes)

Porosity is like Swiss cheese inside your weld. It is almost always a gas issue.

Cause: Wind blowing gas away, a clogged nozzle, or a leak in the gas hose.

Solution: Check your flow meter (set to 25-35 CFH), clean your nozzle of spatter, and block any drafts in your work area.

3. Undercut (Groove at the Edges)

Undercutting leaves a "gutter" at the edges of the weld, which weakens the joint.

VII. Consumable Maintenance: Don't Ignore the Small Stuff

Your machine can be perfect, but if your consumables are worn, your arc will be erratic.

The Liner: This is the most common source of feeding issues. Blow out your liner with compressed air every time you change a wire spool to remove dust and copper flaking.

Contact Tips: If the hole in your tip becomes oval-shaped ("keyholing"), your arc will start to wander. Replace the tip immediately.

Drive Rolls: Ensure your drive roll tension is just tight enough to feed the wire. Too much tension can deform the wire, leading to "birdnesting" in the feeder.

VIII. Why Choose Megmeet Welding Machines for MIG Short Circuit Welding?

Megmeet welding machines are engineered to deliver superior performance, control, and reliability for MIG short circuit welding applications. Whether you are fabricating mild steel components or producing high-quality assemblies in automotive, fabrication, or general manufacturing, Megmeet equipment provides the precision and consistency needed for optimal results.

Key Reasons to Choose Megmeet:

Precision Short Circuit Control: Megmeet MIG welders offer advanced arc control technology that stabilizes the short circuit transfer process, reducing spatter and ensuring smooth, repeatable welds even at low currents.

Optimized Parameter Settings: Built-in, industry-tested parameter presets and customizable settings allow operators to quickly dial in ideal voltage, wire feed speed, and inductance for a wide range of materials and thicknesses.

Robust and Durable Design: Megmeet machines are designed for industrial duty cycles, with rugged construction and high-quality components that withstand demanding production environments and minimize downtime.

Energy Efficiency and Performance: Megmeet power sources leverage modern inverter technology to maximize energy efficiency while delivering consistent welding output, reducing operating costs without sacrificing arc quality.

Comprehensive Support and Service: Customers benefit from Megmeet’s global support network, including technical training and application guidance to help optimize welding processes and troubleshoot challenges.

Scalability for Production Needs: From benchtop units for light fabrication to high-output systems suitable for automated welding lines, Megmeet offers scalable solutions that grow with your production demands.

FAQs of MIG Short Circuit Welding

Q1: Can I weld stainless steel with short circuit MIG?

Q2: Why is my welder producing "birdnesting"?

Q3: Is "Push" or "Pull" better for short circuit?

For thin materials, a "Push" (forehand) technique is better because it produces a flatter bead and more manageable heat. For thicker materials where you need deeper penetration, a "Pull" (backhand) technique is often preferred.

Q4: Can I use short circuit MIG for 1/2-inch thick steel?

It is not recommended for a single pass. Short circuit lacks the energy to penetrate deeply into thick metal, risking "cold lap." For materials over 1/4 inch, it is safer to use Spray Transfer or multiple passes with high-heat settings.

Q5: How do I know if my gas flow is correct?

Set your regulator to between 25 and 35 cubic feet per hour (CFH). If you weld in a breezy area, you may need a bit more, but too much flow creates turbulence that actually pulls air into the weld, causing porosity.

Related articles:

1. MIG Welding Aluminum: Essential Insights and Best Practices

2. An in-depth Guide for MIG Welding Automotive Parts

3. Vertical MIG Welding: Tips, Techniques, and Patterns

4. Exhaust Pipes MIG Welding Guide: Tips, Settings, and Practices

5. Mastering MIG Welding Tips for High Carbon Steel Welding