Whether you’re just getting started with the TIG (Tungsten Inert Gas) welding process — also called GTAW (Gas Tungsten Arc Welding) — or you’ve done a bit and want to improve, this guide will walk you through the key tips and techniques that separate good welds from great ones. You’ll find clear, practical, and actionable advice for both beginner and intermediate welders.

I. Why TIG Welding Is Different — and What to Expect

TIG welding uses a non-consumable tungsten electrode and an inert gas (typically pure argon) to create a clean, controlled weld pool. Unlike MIG welding, the filler wire is fed manually, and the heat input is finely adjustable, giving you full control over every aspect of the weld.

| Feature | TIG Welding (GTAW) | MIG Welding (GMAW) |

|---|

| Electrode type | Non-consumable tungsten | Consumable wire electrode |

| Shielding gas | Argon or argon-helium mix | CO₂ or argon-CO₂ mix |

| Weld appearance | Clean, smooth, minimal spatter | Slightly rougher, possible spatter |

| Control level | High (ideal for precision work) | Moderate (easier for beginners) |

| Best for materials | Stainless steel, aluminum, titanium | Mild steel, stainless steel, aluminum |

| Speed | Slower, focused | Faster, production-oriented |

TIG is especially valued in industries like aerospace, automotive, food equipment, and precision manufacturing, where weld appearance and metallurgical quality matter as much as strength.

II. Set-Up & Preparation for TIG Welding: The Foundation of a Good Weld

Before striking your first arc, preparation is everything. A well-prepared setup often determines whether your weld succeeds or fails.

1) Cleanliness Is Key

TIG welding is highly sensitive to contaminants such as oil, grease, dust, and oxidation. Even small residues can cause porosity or weak welds.

Cleaning checklist:

Use dedicated stainless steel brushes for each metal type.

Wipe the workpiece with acetone or alcohol before welding.

Remove oxides (especially from aluminum surfaces).

Always handle cleaned filler rods with gloves to prevent oil transfer.

2) Proper Workspace Setup

TIG welding requires focus and steady coordination between both hands and the foot pedal.

To minimize fatigue:

Work in a stable seated position if possible.

Support your torch hand on the bench or a rest bar for control.

Keep cables and hoses neatly arranged to avoid pulling or snagging.

Ensure good ventilation to remove shielding gas buildup.

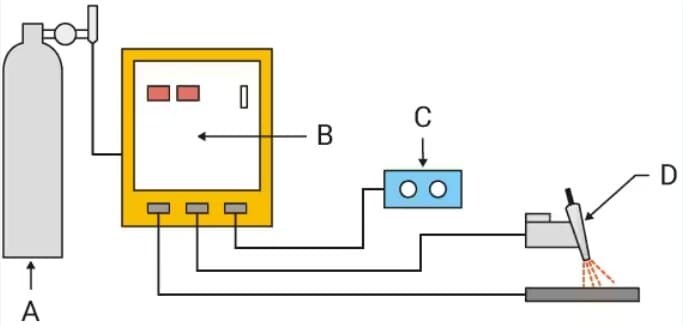

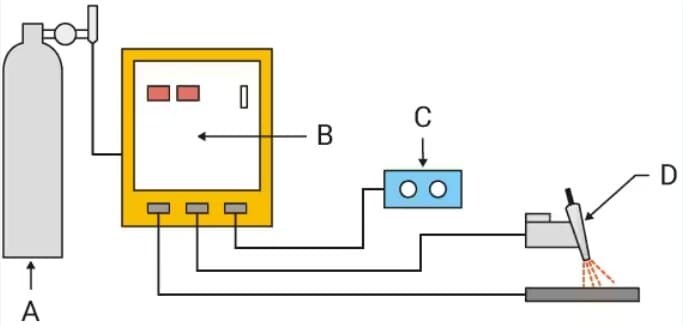

3) Equipment Overview

| Component | Function | Key Setup Notes |

|---|

| Power Source | Supplies current (DC/AC) | Use DC for steels, AC for aluminum |

| Torch | Directs arc to workpiece | Choose torch rated for intended amperage |

| Electrode (Tungsten) | Maintains stable arc | Select correct size/type for current |

| Filler Rod | Adds metal to joint | Match alloy to base material |

| Shielding Gas | Protects weld pool from atmosphere | Use pure argon or argon-helium mix |

| Foot Pedal / Hand Control | Regulates amperage | Allows fine control during welding |

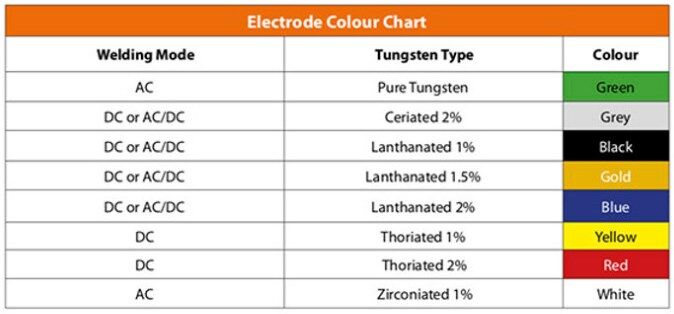

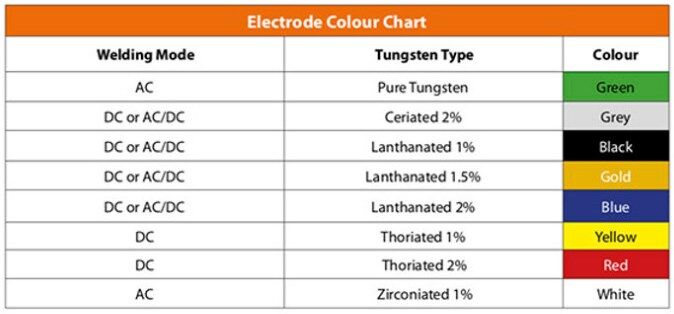

III. Choosing the Right Tungsten Electrode

Tungsten selection affects arc stability, start quality, and contamination resistance.

| Tungsten Type | AWS Color Code | Current Type | Typical Use |

|---|

| Pure Tungsten | Green | AC | Aluminum, magnesium |

| 2% Thoriated | Red | DC | Carbon steel, stainless steel |

| 2% Ceriated | Grey | DC/AC | General-purpose; easy arc start |

| 2% Lanthanated | Blue | AC/DC | Stable arc, long life |

Tip shape:

IV. Setting Amperage, Gas Flow, and Arc Length

Finding the right settings is crucial for control and penetration.

| Material | Thickness (mm) | Amperage Range (A) | Electrode Size (mm) | Filler Rod (mm) | Gas Flow (L/min) |

|---|

| Mild Steel | 1.0 – 3.0 | 30 – 90 | 1.6 | 1.6 | 6 – 8 |

| Stainless Steel | 1.0 – 3.0 | 40 – 100 | 1.6 | 1.6 | 7 – 9 |

| Aluminum | 1.5 – 4.0 | 60 – 120 | 2.4 | 2.4 | 8 – 10 |

| Copper / Brass | 1.0 – 3.0 | 70 – 130 | 2.4 | 2.4 | 8 – 10 |

Arc length rule:

V. Mastering Torch and Filler Coordination

1) Torch Control

Maintain a 10°–15° torch tilt in the travel direction.

Keep the arc short and consistent.

Avoid touching the tungsten to the weld pool or filler rod — contamination ruins arc quality.

2) Filler Feeding

Keep the filler rod inside the shielding gas zone.

Dip the rod gently into the leading edge of the puddle, not the center.

For rhythm practice, tap filler every second — dip, pause, move — to maintain uniform bead ripples.

Pro Tip: Practice “dry runs” — moving the torch and filler together without striking an arc. This builds muscle memory and improves steadiness.

VI. Managing Heat Input

Heat control is one of the defining challenges of TIG welding.

Tips to Control Heat:

Use the foot pedal to fine-tune current as the puddle develops.

Travel steadily — too slow causes overheating and distortion, too fast causes lack of fusion.

For thin materials, try pulsed TIG mode (if available) to maintain penetration without overheating.

Use chill bars or copper backing to absorb heat on thin sheets.

VII. Common TIG Welding Problems and Fixes

| Issue | Likely Cause | Solution |

|---|

| Porosity | Contaminated base metal or filler; poor gas shielding | Clean thoroughly; check for drafts; ensure proper gas flow |

| Tungsten contamination | Tungsten touched weld pool or filler | Regrind tungsten; reduce arc length |

| Lack of fusion | Travel too fast or low amperage | Slow down; increase current |

| Burn-through | Too much heat on thin metal | Lower amperage; use pulsed TIG; faster travel |

| Oxidized weld color | Gas flow interrupted or too low | Increase flow rate; check for leaks |

| Distortion | Overheating or prolonged heat input | Use tack welds, proper clamping, and faster travel |

VIII. Intermediate Techniques — Level Up Your TIG Welding

Once you’ve mastered the basics, it’s time to refine your control, consistency, and versatility.

effect.jpg)

1) Practice with Different Joints:

Work on butt, lap, fillet, and corner joints in all positions (flat, vertical, overhead).

Each requires adjusting your torch angle and travel speed slightly.

2) Experiment with Pulse TIG:

Pulsed current alternates between high and low amperage.

Benefits:

3) Use a Gas Lens:

4) Keep a Welding Log:

Record your settings, material type, and results. Over time, this builds your personal “database” of successful TIG parameters — invaluable for consistency.

IX. TIG Welding Safety Essentials

Even though TIG produces less spatter and fumes than other processes, safety remains critical:

Wear a proper auto-darkening helmet (shade 10–12).

Use leather gloves and long-sleeve flame-resistant clothing.

Ensure grounding cables are tight and clean.

Ventilate your workspace, especially when welding stainless steel or exotic alloys.

X. Quick Reference TIG Welding Table

| Metal Type | Current Type | Polarity | Recommended Tungsten | Shielding Gas |

|---|

| Mild Steel | DC | Straight polarity (DCEN) | Thoriated or Lanthanated | 100% Argon |

| Stainless Steel | DC | DCEN | Ceriated or Lanthanated | 100% Argon |

| Aluminum | AC | — | Pure or Lanthanated | Argon / Argon-Helium mix |

| Copper | DC | DCEN | Thoriated | Argon |

Conclusion

TIG welding is often described as the “art form” of welding — it rewards precision, patience, and discipline. For beginners, focus on fundamentals: cleanliness, torch angle, and steady filler rhythm. As you advance, fine-tune heat control, explore pulsing, and build comfort across positions and materials.

Remember:good TIG welders aren’t born — they’re built through repetition and reflection. Every bead you lay down teaches you something new about how heat, metal, and movement interact.

Related articles:

1. MIG/MAG, MMA, TIG Welding: Choosing the Right Technique

2. TIG Welding: What is Scratch-Start, Lift-Arc and HF Ignition?

3. About Tungsten in TIG Welding: Types, Selection and Use

4. Welding Tips: 6 Secrets of Beautiful TIG Welding

5. How to Solve 10 Common TIG Welding Problems [Guide]

effect.jpg)