Choosing the right welding process is often the difference between a project that succeeds and one that fails under stress or looks unprofessional. Whether you are setting up a small workshop, managing a large-scale manufacturing line, or doing a quick repair on a farm, you have likely encountered the "Big Three" of the welding world: MIG, TIG, and Arc (Stick) welding.

Each method has its own physics, specialized equipment, and ideal use cases. While a MIG welder might be the "speed demon" of the shop, a TIG welder is the "perfectionist," and an Arc welder is the "rugged survivor" that works where others can't. This guide breaks down exactly how these processes work, where they shine, and how to pick the right one for your specific job.

I. Understanding the Fundamentals: What Is Arc Welding?

Strictly speaking, "Arc Welding" is a broad category that includes MIG and TIG. However, in the industrial world and among most professionals, the term Arc welding (or Stick welding) specifically refers to Shielded Metal Arc Welding (SMAW).

This process uses a consumable electrode—a metal rod coated in a chemical flux. When you strike the rod against the base metal, it creates an electric arc that generates intense heat, melting both the rod and the workpiece. As the flux coating burns, it creates a "smoke" or gas shield that protects the molten metal from the air, and it leaves behind a layer of "slag" that must be chipped off after the weld cools.

1) Pros of Arc/Stick Welding:

Rugged and Portable: It doesn't require high-pressure gas cylinders, making it easy to move around.

Outdoor King: Because it doesn't rely on a delicate shielding gas, wind doesn't affect it. It is the go-to for construction sites and farm repairs.

Forgiving: It can weld through rust, paint, and dirt better than any other process.

2) Cons of Arc/Stick Welding:

Messy: Produces significant spatter and a thick layer of slag that requires manual cleanup.

Not for Thin Metal: The intense heat makes it very difficult to weld thin sheets without burning holes through them.

II. The Production Powerhouse: What Is MIG Welding?

MIG (Metal Inert Gas) welding, technically known as Gas Metal Arc Welding (GMAW), is often described as the "point-and-shoot" method of welding. Instead of a single rod, a MIG machine uses a continuous spool of wire that is fed through a gun at a speed you control. An external tank of gas (usually an Argon/CO2 mix) flows through the gun to protect the weld pool.

1) Pros of MIG Welding:

Speed and Efficiency: It is the fastest manual process for long, continuous welds, making it perfect for manufacturing.

Easy to Learn: Most beginners can produce a decent-looking bead in minutes because the wire feed is automated.

Clean Finishes: Very little spatter compared to Arc welding, and no slag to chip off.

2) Cons of MIG Welding:

Indoor Use Only: Even a slight breeze can blow away your shielding gas, causing "porosity" (tiny holes) in the weld.

Bulky Equipment: You need a gas tank, a regulator, and a wire feeder, which limits portability.

III. The Precision Artist: What Is TIG Welding?

TIG (Tungsten Inert Gas) welding, or Gas Tungsten Arc Welding (GTAW), is the most surgical of the three. It uses a non-consumable tungsten electrode to create the arc. Unlike MIG or Arc, the electrode doesn't melt. Instead, you hold a torch in one hand to create the heat and manually dab a separate filler rod into the pool with your other hand, often controlling the heat with a foot pedal.

effect.jpg)

1) Pros of TIG Welding:

Extreme Precision: Ideal for thin-gauge metals and intricate work like roll cages, artwork, or aerospace parts.

Superior Aesthetics: Produces the cleanest, most beautiful welds (the famous "stack of dimes" look).

Zero Spatter: Because the process is so controlled, there is virtually no mess.

2) Cons of TIG Welding:

Difficult to Master: Requires high levels of coordination between your hands and feet.

Very Slow: It is a methodical process that takes much longer than MIG or Arc.

Strict Cleanliness: The metal must be perfectly clean; even a fingerprint can ruin a TIG weld.

IV. Quick Comparison Table: Which Process Fits Your Project?

| Feature | MIG Welding | TIG Welding | Arc (Stick) Welding |

| Learning Curve | Easy (Fastest to learn) | Hard (Steep curve) | Medium (Intermediate) |

| Welding Speed | Fast | Slow | Medium |

| Precision | Medium | High (Best for detail) | Low |

| Aesthetics | Clean | Beautiful/Seamless | Rough (Slag/Spatter) |

| Best Material Thickness | Thin to Thick | Very Thin | Thick/Heavy Plates |

| Outdoor Capability | Poor (Wind issues) | Poor | Excellent (Wind-resistant) |

| Equipment Portability | Low (Gas tank/Feeder) | Low | High (No gas required) |

V. Deep Dive: The Differences in Shielding Gas and Heat Input

The primary difference in these processes lies in how they manage the Heat-Affected Zone (HAZ)—the area of base metal that hasn't melted but has its properties changed by the heat.

In TIG welding, the heat is highly concentrated. You can pinpoint exactly where the energy goes, which keeps the HAZ small and reduces the risk of warping (distortion) on thin materials. In MIG welding, the heat is more spread out. While this allows for faster travel speeds, it can lead to more heat buildup in the material.

Heat input (Q) is a vital calculation for industrial projects to ensure the metal doesn't become brittle. The formula often used is:

formula.png)

Where V is voltage, I is amperage, v is travel speed, and u is the thermal efficiency (roughly 0.8 for MIG/Arc and 0.6 for TIG).

Shielding Gas Nuances:

MIG: Typically uses a "75/25" mix (75% Argon, 25% CO2). The CO2 is an "active" gas that helps the arc penetrate deeper into the steel.

TIG: Almost always uses 100% pure Argon. Because TIG is a delicate process, any active gas like CO2 would quickly contaminate the tungsten electrode.

Arc: Does not use gas tanks. The shielding is built directly into the "stick" coating, which vaporizes as you weld.

VI. Industrial Applications: Where the "Big Three" Are Used

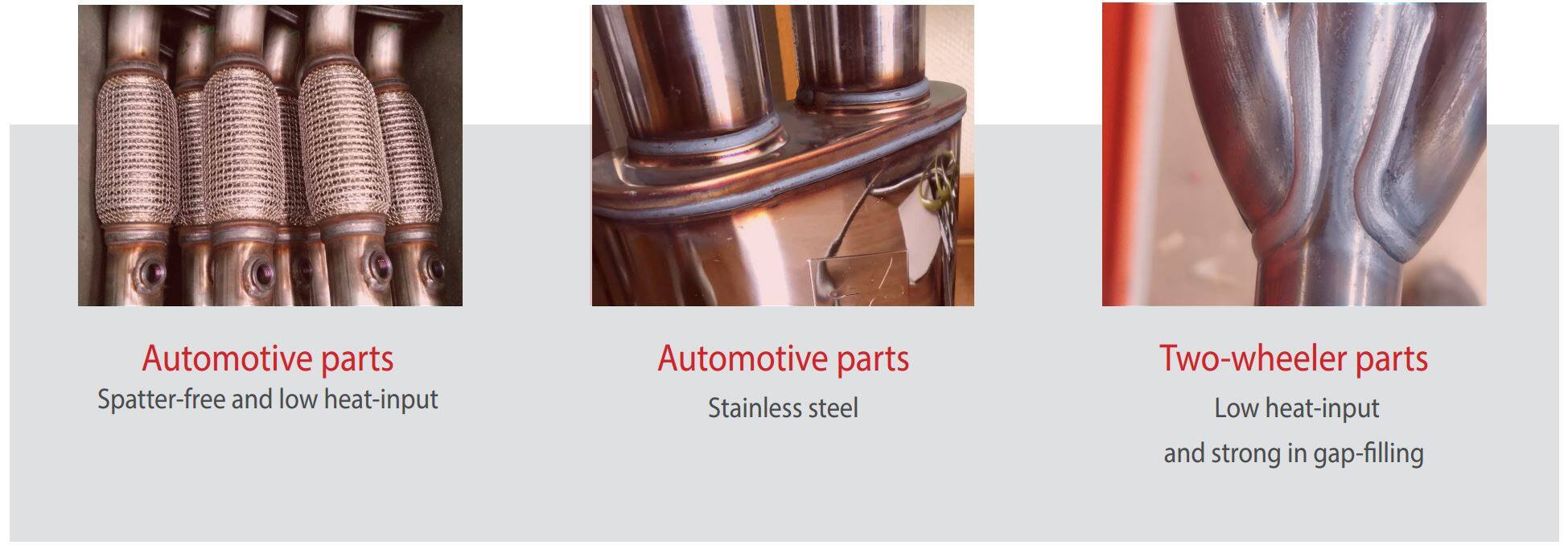

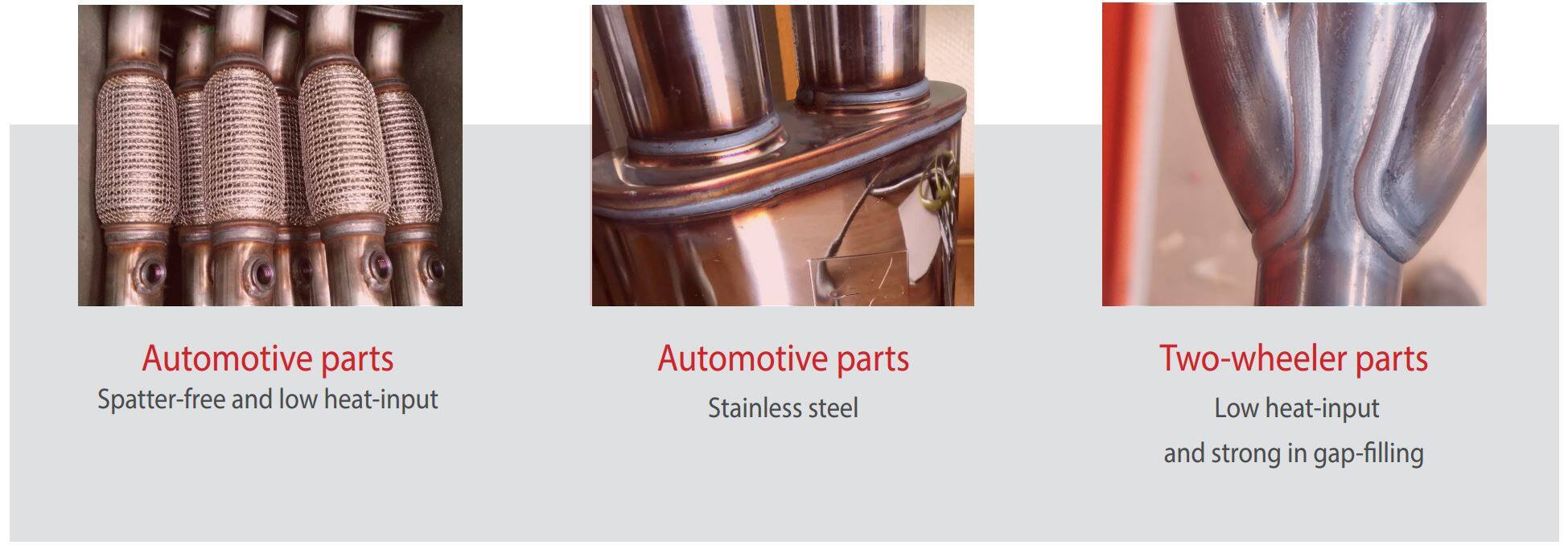

1. Automotive and Transportation:

MIG is the king of the assembly line. From welding car frames to exhaust systems, its speed and ability to handle varying thicknesses make it indispensable. TIG is reserved for custom work, like high-performance roll cages or aluminum body panels, where strength and appearance are critical.

2. Heavy Construction and Infrastructure:

Arc (Stick) welding dominates bridge building, skyscraper skeletons, and pipeline repairs. Its ability to work in high winds and on thick, scaly steel makes it the only choice for fieldwork.

3. Food, Pharmaceutical, and Aerospace:

TIG is mandatory here. In food and medical processing, welds must be perfectly smooth to prevent bacteria from growing in small pores. TIG provides the "sterile" finish and absolute penetration required for these high-stakes environments.

VII. FAQs

Q1: Can I use the same machine for all three processes?

Some modern "multi-process" welders can do MIG, TIG, and Stick. However, specialized TIG work (especially on aluminum) usually requires a dedicated AC/DC TIG machine with a foot pedal for the best results.

Q2: Which technique is cheapest to start?

Arc (Stick) welding is the most affordable. The machines are simpler, and you don't need to rent or buy gas cylinders. MIG has a medium startup cost, while TIG is usually the most expensive due to higher equipment and gas costs.

Q3: Is MIG or TIG stronger?

Technically, both can produce full-strength welds. TIG is often considered "stronger" in precision applications because the focused arc ensures better root penetration with fewer defects. However, a properly set MIG weld on thick plate steel is just as structurally sound.

Q4: Why can't I use MIG outdoors?

The shielding gas is very light. Even a small breeze can disrupt the gas blanket, exposing the molten metal to the air. If you must weld outdoors with a wire-fed machine, you should use Flux-Cored Arc Welding (FCAW) wire, which works like an Arc welder in wire form and doesn't need gas.

VIII. Elevating Performance with Megmeet Digital Inverters

As technology advances, the lines between these processes are becoming even more refined through digital control. Megmeet, a global leader in high-performance welding technology, offers industrial-grade solutions that take the guesswork out of these differences.

Megmeet welders utilize full digital IGBT inverter technology, operating at an ultra-high frequency of 110kHz. This high-precision control allows for:

Low-Spatter-Arc (LSA) Technology: Reducing spatter by up to 90% in MIG processes, bringing MIG finishes closer to TIG-quality smoothness.

Intelligent Expert Databases: Pre-programmed parameters for carbon steel, stainless, and aluminum, making it easier for operators to switch between different materials with high precision.

Extreme Stability: Their digital systems compensate for cable length and power fluctuations, ensuring that whether you are doing heavy-duty Arc welding or high-speed MIG production, the arc remains perfectly stable.

By integrating Megmeet's advanced power sources into your workflow, you can maximize the speed of MIG, the precision of TIG, and the reliability of Arc welding while significantly reducing energy consumption and post-weld cleanup time.

Related articles

1. Cold Metal Transfer (CMT) Welding VS. Retract Droplet Transfer (RDT) Welding

2. Pulsed vs. CW Laser Welding: Key Differences | Expert Insights

3. GMAW vs. CO2 Welding: A Comparison of Two Metal Arc Welding Processes

4. Laser Welding Vs. Arc (TIG) Welding

5. Traditional Welding vs. Laser Welding

FAQs on Welding Techniques

Q1: Which welding type is best for beginners?

A1: MIG welding is often recommended for beginners due to its ease of use and forgiving nature.

Q2: Can TIG welding be used for thick materials?

A2: While TIG welding is more commonly used for thin materials, it can also be used for thicker metals with the appropriate settings and technique.

A3: The primary differences between MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding lie in their techniques, applications, and the characteristics of the welding processes.

Q4: Is Arc welding suitable for outdoor use?

A4: Yes, Arc welding is suitable for outdoor use, making it ideal for construction and repair jobs conducted in open environments.

Q5: Are there eco-friendly variations of these welding methods available?

A5: Yes, there are eco-friendly variations and advancements within welding methods that prioritize environmental considerations. Some developments aim to reduce the environmental impact associated with traditional welding techniques. For example Cold Metal Transfer (CMT) Welding, Pulsed MIG (PMIG) Welding, Inverter-Based Welding Machines...

effect.jpg)

formula.png)