Laser welding is a highly precise and efficient welding technique used in various industries for joining metals with exceptional accuracy. When it comes to laser welding, two primary methods are commonly employed: pulsed laser welding and continuous wave (CW) laser welding. Understanding the differences between these two methods is crucial for selecting the most suitable approach for specific welding applications.

I. Pulsed Laser Welding

1) How pulsed laser welding work?

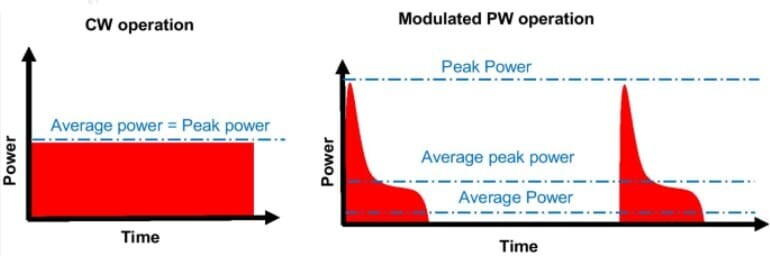

Pulsed laser welding operates by delivering laser energy in intermittent pulses, with precise control over pulse duration and frequency. This modulation of energy allows for controlled heating and melting of the material, resulting in precise welds with minimal distortion.

2) Advantages of pulsed laser welding:

The advantages of pulsed laser welding are manifold, making it a preferred method in diverse industrial applications. Here are some key benefits:

Precise Heat Control: Pulsed laser welding allows for precise control over heat input to the workpiece. This results in minimal thermal distortion and reduces the risk of heat-affected zones (HAZ), preserving the integrity of the welded material.

Controlled Weld Parameters: With pulsed laser welding, operators can modulate pulse duration and frequency, enabling precise control over weld depth and width. This level of control is crucial for applications requiring fine detail and accuracy.

Reduced Distortion: By delivering laser energy in short, controlled pulses, pulsed laser welding minimizes distortion in the welded material. This is particularly advantageous for welding thin materials or components with tight dimensional tolerances.

Versatility: Pulsed laser welding is versatile and can be used to weld a wide range of materials, including metals, alloys, and some plastics. This versatility makes it suitable for various industries, from automotive and aerospace to electronics and medical device manufacturing.

High Weld Quality: The precise control over heat input and weld parameters results in high-quality welds with excellent mechanical properties. This is essential for applications where weld strength, integrity, and aesthetics are critical.

II. Continuous Wave (CW) Laser Welding

1) Mechanism of CW laser welding

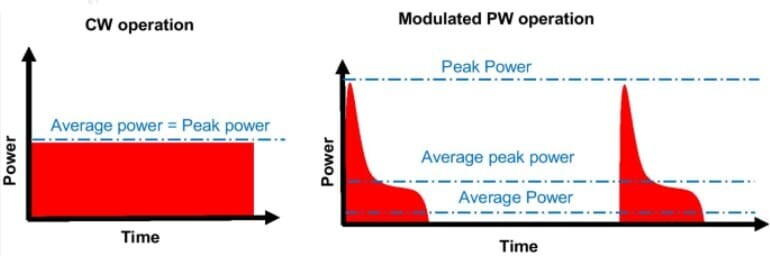

CW laser welding operates by delivering a continuous beam of laser energy to the workpiece, maintaining a constant energy output throughout the welding process. This continuous delivery of energy ensures consistent heating and melting of the material, resulting in stable and uniform welds.

2) Advantages of CW laser welding

Continuous Wave (CW) laser welding offers several distinct advantages:

High Welding Speeds: CW laser welding operates with a continuous beam of laser energy, allowing for rapid welding speeds. This makes it ideal for applications requiring quick turnaround times and high-volume production.

Enhanced Stability and Consistency: The continuous delivery of energy in CW laser welding ensures stable and consistent welds. This results in uniform weld quality and minimizes the risk of defects, contributing to overall process reliability.

Efficient Heat Transfer: CW laser welding efficiently transfers heat to the workpiece, enabling deep penetration and strong welds, particularly in thick metal components. This makes it suitable for welding applications where robust welds are essential.

Versatility in Material Thickness: CW laser welding excels in welding thick materials, providing the necessary power density to achieve deep penetration and strong fusion. It is commonly used in applications involving heavy-duty components or structures.

Suitability for High-Speed Production: Due to its high welding speeds and stable operation, CW laser welding is well-suited for integration into high-speed production lines. It enables rapid throughput while maintaining consistent weld quality, optimizing overall manufacturing efficiency.

Minimal Heat Affected Zone (HAZ): The efficient heat transfer in CW laser welding results in minimal heat-affected zones (HAZ) in the surrounding material. This helps to preserve the mechanical properties of the workpiece and reduces the risk of distortion or damage.

III. Application Areas Comparison

1) Pulsed laser welding applications

Pulsed laser welding is well-suited for applications involving thin sheet metal welding, where precise control over heat input and minimal distortion are essential. Additionally, it is commonly used in precision welding of small components, such as medical devices and electronics, where fine detail and accuracy are critical.

2) CW laser welding applications

CW laser welding excels in welding thick metal components, where high power density and efficient heat transfer are required to achieve deep penetration and strong welds. It is also widely used in high-speed production lines, such as automotive manufacturing, where rapid welding speeds are necessary to meet production demands.

To know 5 Applications of Laser Welding in Industries (Advantages & Cases)

IV. Considerations for Material Compatibility

1) Pulsed laser welding considerations

When considering pulsed laser welding, it is essential to take into account the sensitivity of the material to heat and the thickness of the material being welded. Additionally, pulsed laser welding may not be suitable for welding highly reflective materials due to the potential for energy loss and inconsistent weld quality.

2) CW laser welding considerations

For CW laser welding, compatibility with thick materials and the ability to manage heat effectively are crucial considerations. Additionally, CW laser welding may be more suitable for welding heat-sensitive materials, as the continuous delivery of energy allows for better control over heat input and minimizes the risk of thermal damage.

To know Essential Considerations for Laser Welding.

V. Conclusion

Choosing between pulsed and CW laser welding methods is a pivotal decision for achieving optimal welding results. The intricate differences in their mechanisms and applications underscore the need to match the technique with specific project requirements, ensuring superior weld quality and efficiency.

FAQs

1. Which welding method is better for thin materials requiring precision?

Pulsed laser welding due to its controlled energy bursts and minimal heat impact.

2. Can CW welding be used for delicate electronics assembly?

While possible, pulsed welding is more suitable due to its precision and minimized heat input.

3. Do these methods impact production costs differently?

Yes, pulsed welding might require more initial investment due to equipment, but CW welding may incur higher operating costs due to energy consumption.

4. Are there industries benefiting equally from both techniques?

Some industries, like automotive manufacturing, leverage both methods based on the application's specifics.

5. How do advancements in laser technology influence these welding techniques?

Advancements continually refine both methods, enhancing precision, speed, and versatility across industries.

Related articles:

1. How Does A Laser Welding Machine Work?

2. Laser Welding vs TIG Welding - What’s the Difference

3. Traditional Welding vs. Laser Welding

4. Laser Welding vs. MIG Welding: Ultimate Comparison Guide

5. Laser Welding: Which Materials Can You Weld?