Aluminum is a material beloved across industries, from aerospace to automotive, thanks to its exceptional strength-to-weight ratio and natural resistance to corrosion. Yet, for metalworkers, it presents a significant challenge: welding it effectively.

The primary difficulty lies in aluminum’s unique chemistry. While pure aluminum melts at a relatively low temperature (around 1,200°F or 660°C), the moment it is exposed to air, it forms a protective layer of aluminum oxide. This oxide layer is incredibly tough, stable, and has a melting point of approximately 3,600°F (1,980°C)—three times higher than the base metal.

If this stubborn oxide layer isn’t removed during the welding process, it prevents proper fusion and leads to inclusions, porosity, and poor-quality welds. This is where Alternating Current (AC) Tungsten Inert Gas (TIG) welding becomes indispensable. AC TIG welding is the precise, controlled solution that simultaneously cleans the surface oxide and provides the necessary heat for deep penetration, delivering the high-quality, aesthetic welds aluminum demands.

Tungsten Inert Gas (TIG) welding Aluminum.jpg)

I. The AC TIG Advantage: Penetration vs. Cleaning

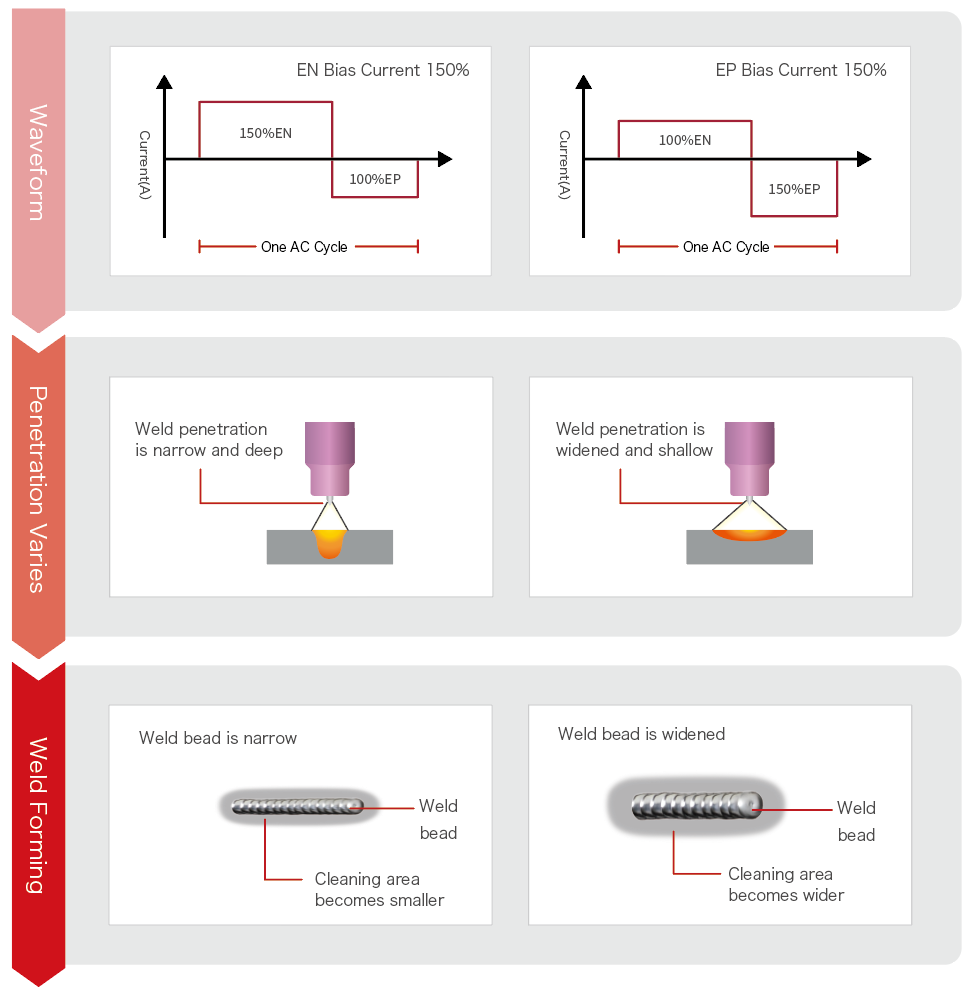

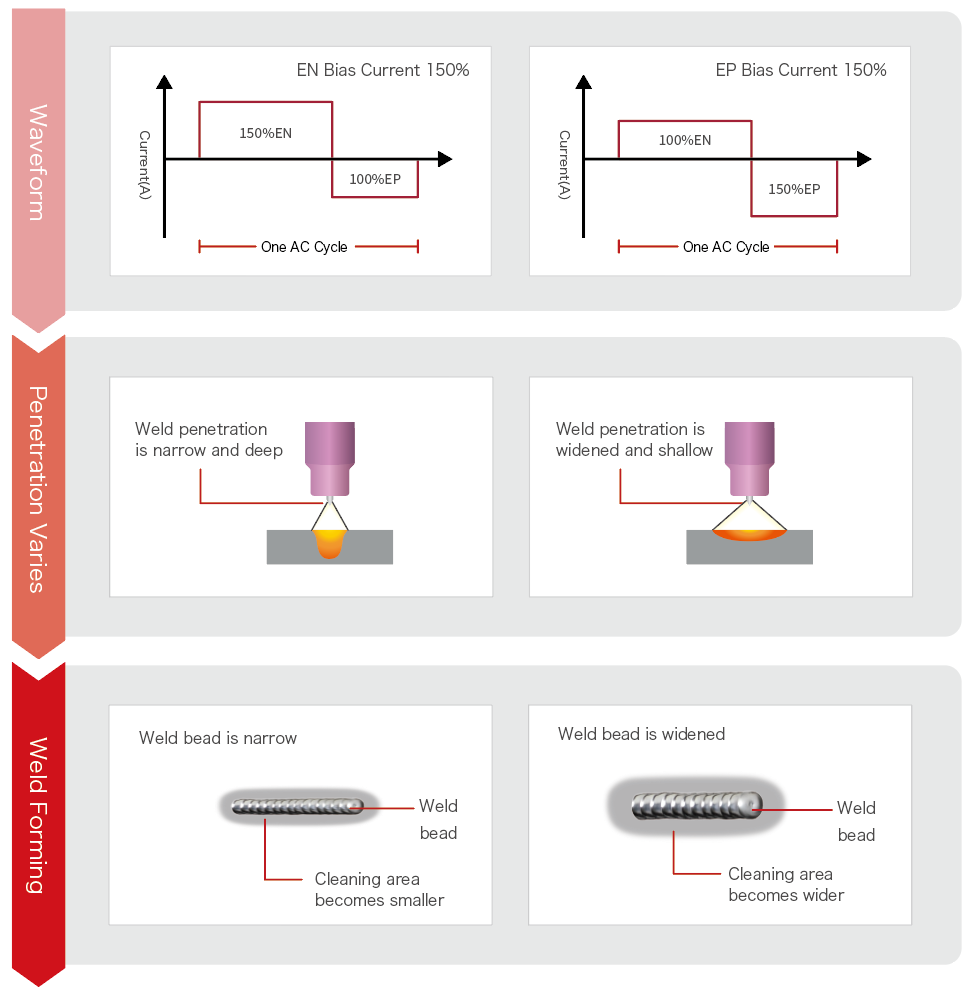

Unlike Direct Current (DC) TIG welding, which only provides penetration, AC welding uses an oscillating current that switches polarity rapidly. This rapid switching allows the welding process to perform two critical, opposing functions required for flawless aluminum welding:

1) Electrode Negative (EN) – The Penetration Phase

When the tungsten electrode is negative (EN, or DCEN), electrons flow from the tungsten into the workpiece. This concentrates heat on the material, providing the deep penetration necessary to melt the aluminum base metal and establish the weld puddle.

2) Electrode Positive (EP) – The Cleaning Phase

When the electrode is positive (EP, or DCEP), electrons flow from the workpiece to the tungsten. This action, known as the “cleaning phase,” blasts away the surface aluminum oxide layer. This action is akin to an ion etching process, clearing the path for the EN cycle to properly fuse the clean base metal underneath.

Result: Effective oxide removal, essential for fusion, but it also focuses heat on the tungsten electrode, potentially leading to erosion or "balling."

In older AC machines, these two cycles were split 50/50. However, modern, sophisticated inverter-based AC TIG welders allow the operator to independently control the time (or percentage) spent in each phase, which is the key to optimizing the weld.

II. Decoding AC Balance Control

AC Balance Control is the single most important parameter when TIG welding aluminum. It defines the ratio of time spent in the penetration (EN) phase versus the cleaning (EP) phase over a single AC cycle. It is typically expressed as a percentage of the EN cycle (e.g., 75% EN).

Adjusting the Balance

The balance setting is a direct trade-off between tungsten longevity/penetration and cleaning action.

| AC Balance Setting (EN %) | EP % (Cleaning) | Effect on Weld and Tungsten | Ideal Applications |

| High EN (75%–80%+) | Low EP (25%–20%) | Increased Penetration, narrow weld bead, reduced etched zone (better appearance), longer tungsten life. | Clean, fresh aluminum; thick plates; automated welding. |

| Low EN (60%–70%) | High EP (40%–30%) | Increased Cleaning Action, wider weld bead, shallow penetration, higher risk of tungsten balling. | Dirty, heavily oxidized, or old aluminum; thin sheet metal (to prevent burn-through). |

Best Practice Starting Points

For most applications on relatively clean aluminum, a good starting point is 65% to 75% EN.

If the weld puddle appears dirty, scummy, or contains "peppering" (small gray or black specks, indicating trapped oxides), the EN percentage is too high. You need to decrease EN (increase cleaning action).

If the tungsten electrode is quickly eroding, deforming, or forming a large ball, the EP percentage is too high. You need to increase EN (reduce heat on the tungsten).

Crucial Note on Prep: AC Balance is the last line of defense. The base material must always be mechanically cleaned with a stainless steel brush dedicated only to aluminum, followed by a solvent wipe (like acetone) to remove oils and debris. A clean part allows you to use a higher EN setting, maximizing penetration and tungsten life.

III. Shaping the Arc: AC Waveforms and Frequency

Modern inverter technology gives the welder unparalleled control by allowing adjustments to the shape of the AC current wave and the speed at which it cycles. These advanced controls are crucial for tailoring the arc behavior to the specific job.

1) Adjustable AC Output Frequency

The AC frequency is the rate (measured in Hertz, Hz) at which the current completes a full cycle (EN to EP and back). While conventional AC machines were limited to the wall frequency (50 or 60 Hz), advanced inverters can adjust frequency from 20 Hz up to 400 Hz.

High Frequency (120 Hz to 400 Hz)

Effect: The arc becomes more focused, narrower, and stable, acting almost like a laser beam.

Benefits: Increased directional control, faster travel speeds, deeper, more precise penetration, and a narrower bead profile. This is ideal for fillet welds, corner joints, and intricate work.

Low Frequency (20 Hz to 80 Hz)

Effect: The arc is softer, wider, and less focused.

Benefits: A wider weld puddle and bead, excellent wetting action, and maximum energy transfer across a broad area. This is ideal for applications requiring heavy metal deposition or filling wide gaps. A standard starting point for general-purpose aluminum is often 120 Hz to 200 Hz.

2) Selecting an AC Waveform

The waveform determines the characteristic and "feel" of the arc and the puddle behavior. Advanced AC TIG welders, such as Megmeet MetaTIG HF AC TIG Welder, typically offer several choices:

Advanced Square Wave: Offers a fast, dynamic, and focused arc. It provides quick transitions, leading to a fast-freezing puddle, deep penetration, and high travel speeds. This is the choice for maximum productivity and control.

Soft Square Wave: Provides a smoother, more "buttery" arc than the advanced square wave. The puddle is fluid and controllable, offering good wetting action for general purpose welding.

Sine Wave: Provides the softest arc, reminiscent of traditional transformer machines. It is often the quietest, offers good wetting action, but provides less directional control than square waves.

Triangular Wave: Reduces the overall heat input into the weld while still allowing for peak amperage to be used. It promotes quick puddle formation, minimizes weld distortion, and is particularly effective for welding thin aluminum materials where warping is a major concern.

IV. Advanced Control: Independent Amperage

For the most demanding or specialized aluminum jobs, advanced AC TIG machines provide Independent Amperage Control (also called Independent Amplitude Control).

Traditionally, when you adjusted the main amperage dial, both the EN and EEffective Cleaning of the Oxide LayerP cycles changed proportionally. With independent control, you can set the EN amperage and the EP amperage completely separately.

How Independent Amperage Maximizes Performance

Optimized Penetration and Tungsten Life: The operator can pour a high amperage (e.g., 300 EN Amps) into the workpiece for deep penetration while dialing back the cleaning current (e.g., 150 EP Amps) to protect the tungsten electrode from excessive heat.

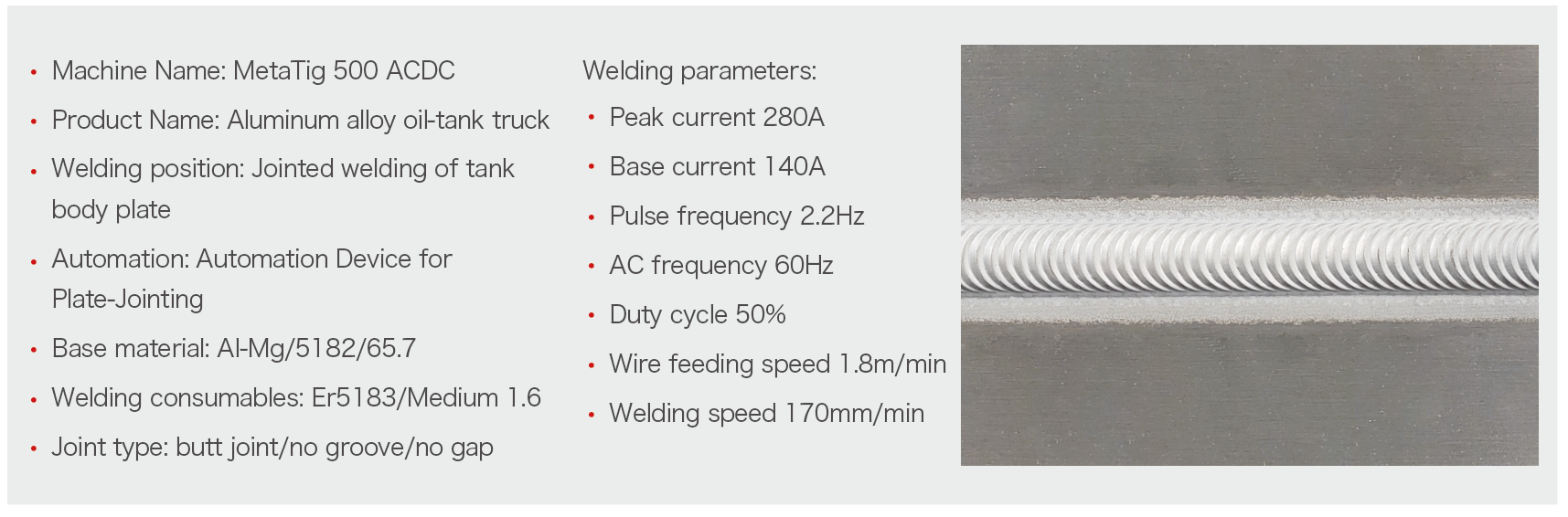

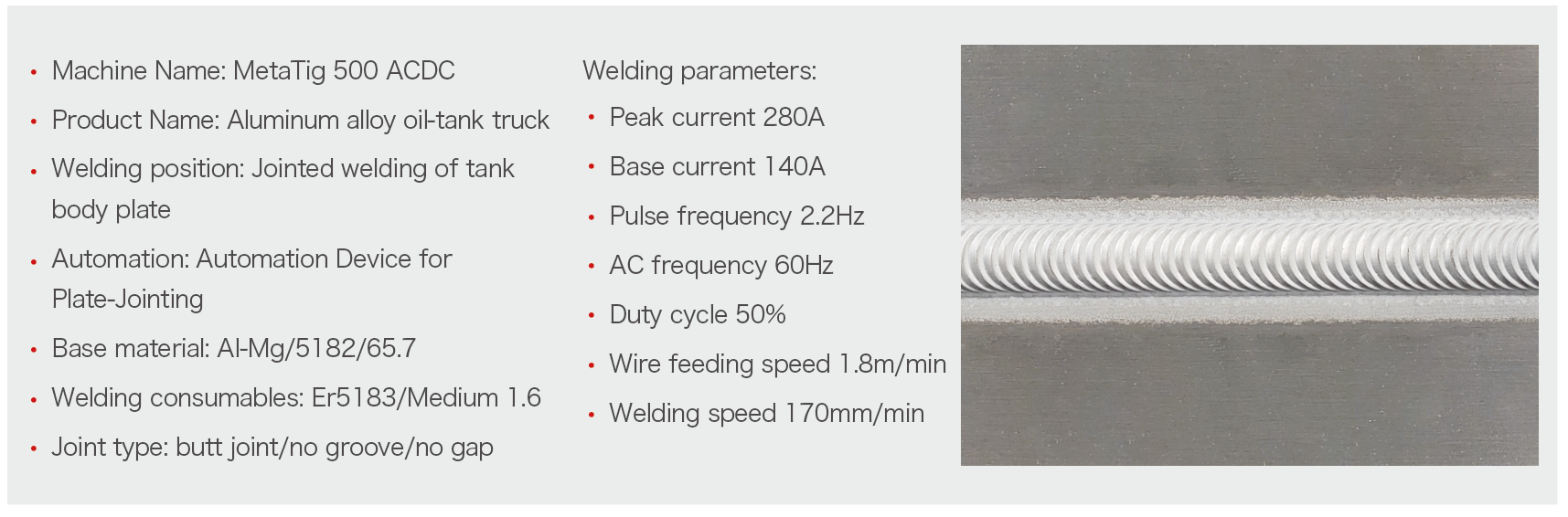

Faster Travel Speeds: By maximizing the EN current, the welder can significantly increase travel speeds and filler metal deposition rates. Case studies have shown that utilizing independent amperage control can dramatically cut production time compared to traditional AC welding methods.

Smaller Tungsten Usage: Reducing the heat directed at the electrode (lower EP amps) permits the use of a smaller-diameter tungsten. A smaller tungsten electrode provides a more focused arc, allowing for greater precision when directing heat into the weld joint.

V. Essential Equipment and Setup for Aluminum

To achieve mastery in AC TIG welding aluminum, the advanced capabilities of the machine must be matched with correct consumables and meticulous preparation. The Megmeet line of advanced inverter-based TIG machines includes features that simplify this setup.

1) Tungsten Electrode Selection

Type: For AC TIG welding, electrodes containing zirconium or rare-earth mixes are often preferred for their ability to maintain a stable arc and resist contamination. Pure tungsten is also used but tends to "ball" more readily than alloyed options.

Tip Preparation: Unlike DC welding, which requires a sharp point, AC welding traditionally requires a balled tip for arc stability. However, with advanced square wave and independent control, a slightly truncated (blunted) point or a pointed tip can often be used to gain directional control while protecting the tungsten from excessive heat.

2) Shielding Gas and Flow

Gas: 100% pure Argon is the standard shielding gas for AC TIG welding aluminum, offering optimal arc stability and cleaning action.

Flow Rate: Ensure the proper flow rate (typically 15 to 25 cubic feet per hour, or CFH) is used. Too little gas leads to contamination; too much causes turbulence, drawing atmospheric air into the weld zone.

3) Key Machine Features (The Inverter Advantage)

Modern TIG machines built on inverter technology, like the Megmeet series, offer capabilities crucial for high-quality aluminum work:

High-Frequency (HF) Start: Essential for initiating the arc without contacting the tungsten to the work. This prevents tungsten contamination, ensuring a clean, smooth start every time.

Pulse Control: Allows the welder to cycle between a high peak current (for penetration) and a low background current (for cooling). This minimizes overall heat input, greatly reducing the risk of distortion or warping when working with thin gauge aluminum or heat-sensitive components.

High Duty Cycle: A machine with a high duty cycle ensures prolonged operation at high amperages without overheating, boosting productivity for large fabrication or high-volume work.

V. FAQs on AC Current in Aluminum TIG Welding

Q1: What causes “peppering” in an aluminum weld puddle?

A: "Peppering" refers to the appearance of small black or grey specs and a scummy surface texture in the weld puddle. This is a clear sign of trapped oxides and contaminants that have not been adequately removed.

Q2: Which AC waveform is best for thin aluminum?

A: The Triangular Waveform is often the best choice for thin aluminum (e.g., sheet metal). The triangular wave rapidly cycles to peak current for quick puddle formation but immediately drops off, significantly reducing the average heat input. This minimizes the time the base metal spends soaking up heat, effectively reducing the risk of burn-through and warping.

Q3: How does increasing AC Frequency affect the noise of the welder?

A: Increasing the AC frequency often makes the machine sound louder or sharper. The sound you hear is the rapid cycling of the AC current. While low-frequency welding (e.g., 60 Hz) can produce a soft, low humming sound, high-frequency welding (e.g., 200–400 Hz) produces a distinctly high-pitched, sharp whining noise. This is a normal function of the controlled current switching inside the inverter.

Q4: Is preheating aluminum ever necessary with modern AC TIG?

A: While advanced features like Independent Amperage Control and high AC frequency significantly reduce the need for preheating, it may still be beneficial when welding extremely thick aluminum sections (e.g., over 1/2 inch) or large, complex fabrications. Preheating reduces the thermal conductivity differential, helping the base metal reach the melting point faster and ensuring proper fusion at the root.

Conclusion

AC TIG welding is the standard for high-quality aluminum fabrication, and modern inverter technology has transformed the process from a difficult art into a precise science. By harnessing the power of independent controls—specifically AC Balance for managing oxide cleaning, AC Frequency for directional arc focus, and Waveform Shaping for puddle dynamics—welders can tailor the arc to virtually any aluminum application.

By investing in high-precision, technologically advanced equipment, such as the powerful TIG welders engineered by Megmeet, and committing to proper preparation and technique, welders can consistently achieve the strong, clean, and aesthetically superior results that define professional aluminum work. Mastering these principles is the key to elevating craftsmanship and maximizing productivity in the world of aluminum welding.

Related articles:

1. AC DC TIG Welding Machine: Unleash Precision with Megmeet

2. Best TIG Welders: Buyer's Guide For TIG AC/DC Welding Machines in 2023

3. AC vs DC Welding: Which One is Better for TIG Welding?

4. Multiprocess Welder with AC TIG -- Benefits, Features and Models

5. Why is AC current preferred in aluminum welding?

Tungsten Inert Gas (TIG) welding Aluminum.jpg)