When setting up welding equipment, one of the key decisions is whether to use alternating current (AC) or direct current (DC) output. This choice influences arc stability, weld penetration, metal compatibility and weld appearance. In this article you’ll learn what AC and DC welding really mean, how their behaviour differs in practice, the pros and cons of each, and guidelines to help you choose the right current for your project.

I. What are AC and DC in welding?

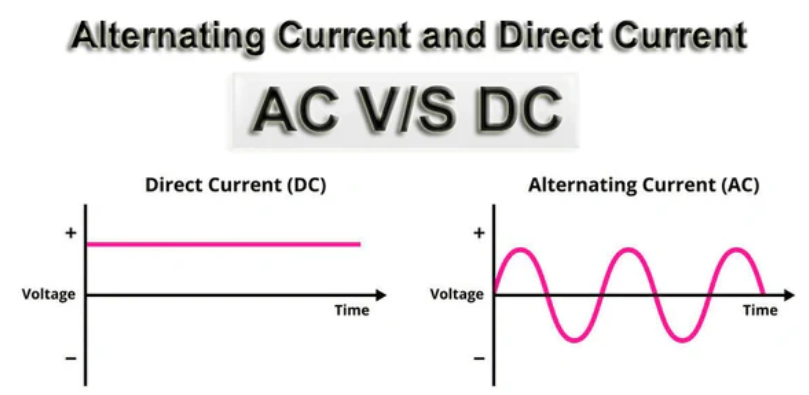

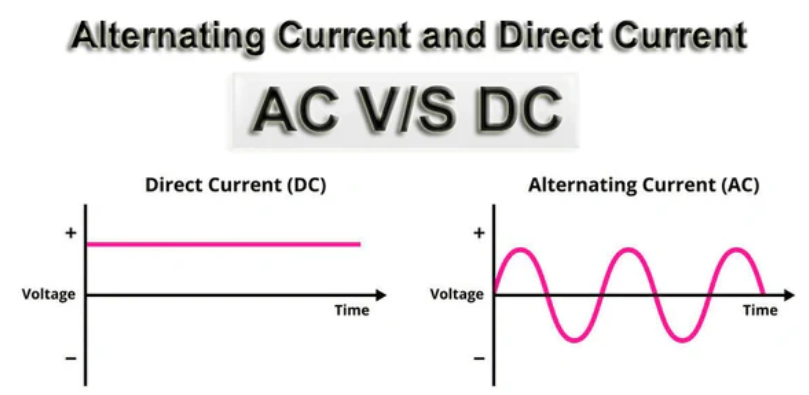

AC (Alternating Current): The current changes direction many times per second (in a 50 Hz system approx. 100 reversals per second; in a 60 Hz system approx. 120) so the welding output alternates between electrode-positive and electrode-negative.

DC (Direct Current): The current flows in one direction only. The electrode may be connected to the negative terminal (DCEN, electrode negative) or to the positive terminal (DCEP, electrode positive).

These distinctions aren’t just theoretical—they have practical effects on the arc, heat distribution, weld pool behaviour, and how the weld reacts to magnetic fields.

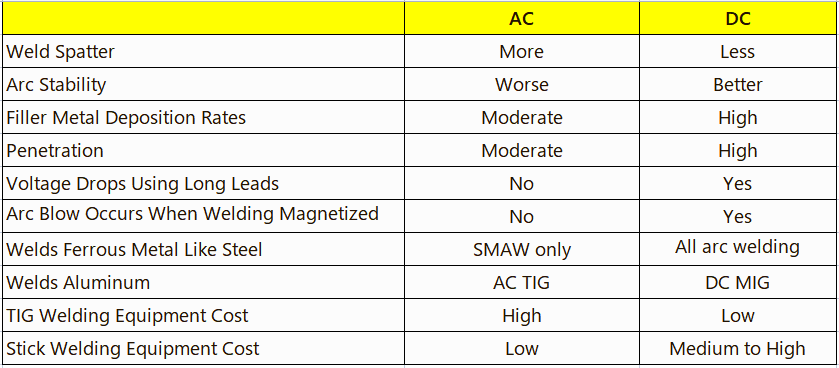

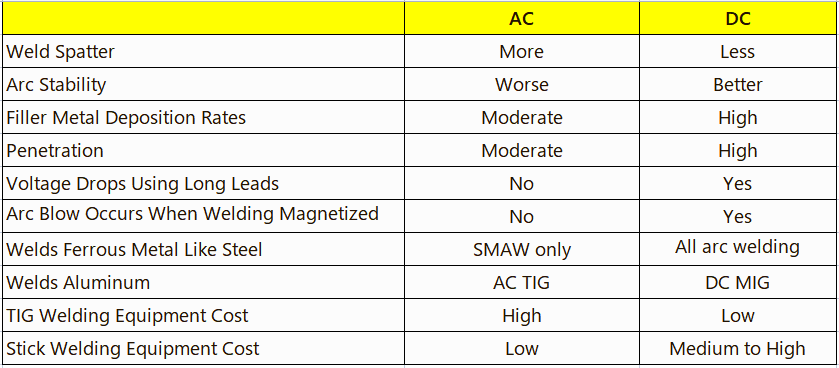

II. Key Differences between DC and AC Welding

1) Arc stability & direction

With DC, the welding current and polarity remain constant, which generally gives a smoother, more stable arc and more predictable puddle behaviour.

By contrast, AC constantly reverses polarity, which can cause the arc to extinguish and reignite at each zero-crossing unless the power source is designed to compensate. This can reduce stability in some cases.

2) Magnetic arc blow

Arc blow is the phenomenon where magnetic fields (often in magnetised parts or corners) deflect the arc away from its intended path. Because AC reverses direction many times per second, the magnetic field does not build a fixed direction strong enough to sustain arc blow—therefore AC helps reduce arc blow.

DC, however, being unidirectional, may be more prone to arc blow in certain geometric or magnetised conditions.

3) Penetration, heat concentration and bead quality

DC welding often provides deeper penetration, more consistent bead appearance, and higher deposition rates (for consumables) because all the heat direction and current is focused in one direction.

AC welding tends to distribute heat more broadly (because of the reversing polarity) and may produce less penetration and a somewhat rougher bead depending on application.

4) Metal/material considerations

Some metals require AC welding because of surface oxides or special cleaning needs (for example aluminium). DC is typically used for a wide range of ferrous metals and many production welding contexts.

5) Equipment cost and flexibility

AC machines can be simpler and cheaper in some circumstances. But machines that can output both AC and DC (or very stable DC) are more flexible—though naturally the more flexible the machine the higher the cost.

III. Pros & Cons of DC and AC Welding– Side-by-Side

| Current Type | Pros | Cons |

|---|

| AC | Better for materials needing cleaning action (oxide removal) and for controlling arc blow in magnetised workpieces. Useful for some non-ferrous alloys. | Arc less smooth in some cases, penetration may be lower, more complex to control unless machine is designed well. |

| DC | More stable arc, smoother bead, better penetration, high productivity for many steels and standard alloys. | More prone to arc blow in some cases, less suited for certain oxides/non-ferrous metals without cleaning, equipment cost may be higher. |

IV. When to choose AC vs DC – Practical guidelines

Here are some practical decision points to guide your selection:

Material type: If you’re welding aluminium or magnesium (which have heavy oxide layers), AC becomes more favourable because the alternating polarity helps “scrub” the oxide layer and improves weld quality.

Magnetised or complex geometry work: If you expect arc blow (corners, magnetised steel, tight geometry), AC may reduce those risks.

Steel, stainless, standard production: DC is often the default choice for its performance and stability.

Access, fit-up and cleaning: If parts are heavily oxidised or the fit is poor and cleaning is limited, using AC might compensate somewhat—but ideally you still clean.

Production volume & cost control: For large-volume steel fabrication, DC gives efficiency advantages.

Equipment capability: What your machine supports (AC only, DC only, or AC/DC) may dictate the choice.

V. Myths & Clarifications

Myth: “AC is inferior to DC in all cases.” – Not correct. AC has valuable uses (especially non-ferrous metals, oxide cleaning, arc blow control).

Myth: “DC always penetrates better.” – In many contexts yes, but if the fit-up is poor, or the oxide layer thick, or the part magnetised, DC may underperform without proper prep.

Clarification: “AC means less heat.” – Not necessarily less heat, but the heat distribution and arc behaviour differ; penetration may differ. Heat input still depends on current, amperage, travel speed etc.

Clarification: “One machine is always better.” – The best machine supports both if you weld a wide variety of materials; but for a focused production job select the optimum for that use.

FAQs on DC Arc Welding in Specialized Applications

Q1. Can I weld steel with AC?

A1: Yes — you can weld steel with AC output, but in many cases DC will give better results in penetration, bead profile and arc stability for steel. AC might be used if the machine only supports AC, or if the job has specific constraints (like magnetised part).

Q2. Why does aluminium often require AC?

A2: Aluminium forms a tenacious oxide layer which has a higher melting point than the base metal. AC output alternates polarity which helps to break up the oxide layer (during positive half-cycle) and then provide fusion (during negative half-cycle). This cleaning action is more difficult with DC alone.

Q3. What is meant by DCEP and DCEN in DC welding?

A3: DCEP (Direct Current Electrode Positive): The electrode is positive, so heat concentrates at the electrode, which can be good for certain filler-metal droplet transfer or stick welding modes.

DCEN (Direct Current Electrode Negative): The electrode is negative, heat concentrates at the workpiece, leading to deeper penetration. For TIG, DCEN is usually preferred.

Q4. Does using DC always prevent arc blow?

A4: No—actually DC can be more prone to arc blow because the direction is constant and residual magnetic fields can deflect the arc. AC, by reversing direction frequently, reduces sustained magnetic build-up and tends to mitigate arc blow especially in magnetised materials or corners.

Q5: My machine supports both AC and DC — how should I choose?

A5: Start with the material and joint requirements:

If you’re working with aluminium, magnesium or a lot of oxide / magnetised parts → favour AC or AC mode.

If you’re welding standard steels, stainless, high-productivity work with clean surfaces → favour DC.

Then refine based on observed arc behaviour, bead appearance, penetration and production speed. Test on scrap first.

Conclusion

AC and DC welding are both powerful tools in the fabricator’s toolbox — neither is universally superior. The choice comes down to material, cleanliness/fit-up, geometry, magnetic conditions, and production goals.

By understanding how AC alternates polarity (and helps cleaning/arc-blow control) and how DC offers stable unidirectional current (improving penetration and bead quality), you can select the correct mode for each job.

When in doubt, perform a brief test on scrap under the expected conditions, evaluate bead integrity, penetration and arc stability, then lock in the mode that best suits your workflow.

Related articles:

1. AC DC TIG Welding Machine: Unleash Precision with Megmeet

2. Best TIG Welders: Buyer's Guide For TIG AC/DC Welding Machines in 2023

3. AC vs DC Welding: Which One is Better for TIG Welding?

4. AC Vs DC Stick Welding – Which One Is The Best & Why?

5. TIG Welding with DC vs. AC Current