When you’re looking at welding processes for carbon and low-alloy steels, especially in fabrication, construction or repair environments, one method that often comes up is Flux-Cored Arc Welding (FCAW). In this article we’ll explore what FCAW is, how it works, where it shines (and where it doesn’t), and answer some frequently asked questions. The goal: clear, technically sound but readable for engineers, procurement specialists and industrial end-users.

.png)

I. Flux-Cored Arc Welding Definition & Process Overview

At its simplest, FCAW is an arc-welding process in which a hollow tubular electrode (wire) continuously feeds into the weld zone, and the wire carries a core of flux. The flux and/or optional shielding gas protect the molten weld pool from atmospheric contamination.

Key characteristics:

Continuous wire feed (rather than stick electrode)

Tubular shell containing flux (and sometimes alloying additives)

Constant-voltage (or less commonly constant-current) power supply

Two basic types: with external shielding gas, or self-shielded (flux provides the protection)

Suitable for many ferrous materials (carbon-steel, some stainless, cast iron) but not ideally for aluminium or other exotic non-ferrous alloys.

Because the flux can generate protective gas and forms slag, FCAW is often more robust in less-ideal conditions (e.g., slightly contaminated base metal, outdoor work) than some other processes.

II. Types of Flux-Cored Arc Welding (FCAW)

We can broadly classify FCAW into two types:

1) Self-Shielded FCAW (FCAW-S)

In this type, the flux core within the electrode provides all the shielding—there is no external shielding gas cylinder. The flux melts, releases protective gases, and forms slag to protect the weld. Because there is no gas bottle to worry about, this is particularly useful outdoors, in windy conditions, or field work sites.

Advantages: portability, fewer external consumables, often more tolerant of surface condition.

Limitations: more smoke/fume, slag removal required, may have somewhat lower finish-appearance quality, and the electrodes may cost more.

2) Gas-Shielded / “Dual Shield” FCAW (FCAW-G)

Here, the tubular flux-cored wire is used with an external shielding gas (often CO₂ or Ar/CO₂ blends), in addition to the flux inside the wire, thus “dual” shielding. This approach is common in heavy fabrication, structural steelwork, and where high productivity and mechanical properties are demanded.

Advantages: higher deposition rates, better mechanical properties (when properly applied), works well in controlled shop environments.

Limitations: external gas means outdoor use may be restricted by wind or travel, more equipment/consumables, operator skill still matters.

III. How FCAW Works – The Technical Mechanism

Here’s a breakdown of the process in more engineer-friendly detail:

Arc initiation: The welding power-source (constant voltage typically) is connected; the hollow electrode (flux-cored wire) is fed through the welding gun. When the wire tip strikes the workpiece (or is close enough), an arc is struck and heat is generated.

Melting the base and filler: The arc melts both the wire (which becomes the filler metal) and the base metal surfaces. The molten filler, molten base metal and flux combine to form the weld pool.

Flux action / shielding: Inside the tubular wire the flux contains compounds that, under arc heating, decompose or react to produce shielding gas and slag. In gas-shielded versions, the external gas helps. This shielding prevents atmospheric gases (oxygen, nitrogen) from contaminating the molten metal.

Slag formation & solidification: After deposition, a layer of slag forms on top of the weld bead (in many FCAW wires). This must typically be removed (chipped or brushed) before subsequent passes or finishing.

Metal solidifies: The molten weld pool cools, the filler metal fuses with the base material, and a sound joint is formed (assuming proper parameters, technique and preparation).

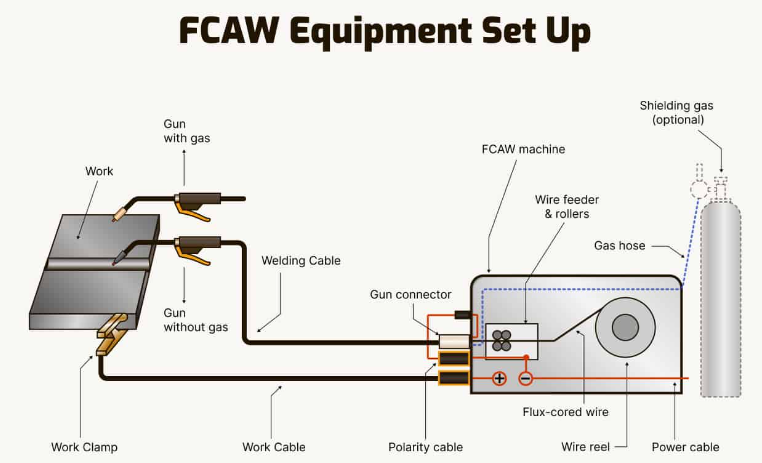

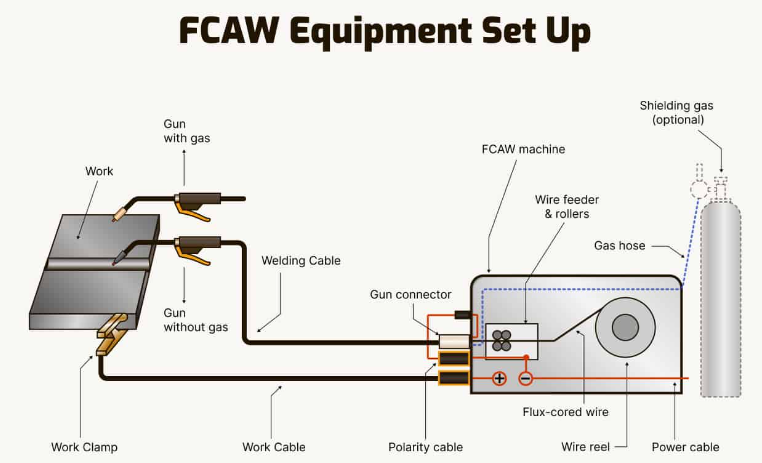

Key equipment & parameters

Power source: constant voltage (most common)

Electrical polarity: often DC electrode negative (straight polarity) for many self-shielded wires; gas-shielded wires may use DC electrode positive depending on wire design.

Wire feed system: suitable drive rolls (knurled for tubular soft wires) to ensure consistent feeding.

Travel speed, wire feed speed, stick-out (unmelted electrode length), gun angle and work preparation are all critical to weld quality. For example, stick-out for flux-cored might be around ¾ in (~19 mm) according to a reference for mild steel.

IV. Where FCAW is Used – Typical Applications

1) Addressing Common Issues

FCAW is widely applied in many sectors. Some common areas include:

Structural steel fabrication (beams, columns, trusses) — especially thick section steelwork.

Construction and infrastructure, including bridges, heavy equipment – where speed and robustness count.

Shipbuilding and marine repairs — field conditions, variable surface prep, large welds.

Pipe welding and pressure vessel fabrication (in certain cases) — where higher deposition rate and positional welding capability help.

Maintenance and repair work, especially outdoors or in wind-exposed places (self-shielded variant works well).

Hard-facing/surfacing alloys (some FCAW wires are designed for hard facing applications).

It’s less common for very thin sheet metal, fine aesthetic welds, or non-ferrous alloys such as aluminium. Some practitioners limit FCAW use to materials above ~20 gauge (~0.9 mm) or thicker, especially the self-shielded type.

V. Advantages & Limitations of FCAW

1) Advantages

High deposition rates: Because the wire continuously feeds and flux aids deposition, FCAW can be faster than stick or some MIG processes.

Good for outdoor / windy conditions (particularly self-shielded variant): No reliance (or less reliance) on external gas shield.

Tolerant of less-than-perfect base metal preparation: Slight rust, scale or drafts can be tolerated (especially self-shielded) compared to some other processes.

All-position capability: With the right wires, FCAW can weld in flat, horizontal, vertical and overhead positions.

Good penetration and mechanical properties (especially the gas-shielded/dual-shield variant) when properly applied.

2) Limitations

Smoke, fume and slag: The flux in the wire generates slag and more fume/smoke than some gas-only processes. Visual weld pool observation may be more difficult.

Slag removal required: After welding, slag must be chipped or brushed off before subsequent passes or finishing.

Equipment & consumables cost: Tubular wire is often more expensive than solid wire, and handling/storage may be more critical (flux must stay dry, wire condition must be good).

Not ideal for very thin materials: Because of slag, higher heat input, and other factors, self-shielded FCAW may not be suitable for delicate, thin workpieces (e.g.,<20 gauge).

Technique and parameter-control still matter: Although more forgiving in some respects, poor wire feed, wrong polarity, poor joint prep or travel speed can lead to defects (porosity, slag inclusions, lack of fusion).

VI. Practical Considerations & Best Practice Tips

1) Joint & material preparation

Clean the base metal as much as practical—while FCAW is tolerant, removing scale, rust or loose contamination will improve results.

Ensure good grounding/clamp contact—poor clamp connection can degrade weld quality.

For thicker sections, bevel edges or ensure suitable joint design to promote complete fusion.

2) Equipment setup

Use correct drive rolls: Tubular wire is softer than solid wire so knurled drive rolls give better “bite” without deforming the wire.

Set correct polarity and machine settings (voltage, wire feed speed) per wire manufacturer guidance or procedure charts.

Stick-out (electrode extension beyond contact tip) typically greater in FCAW than MIG—e.g., ~¾ inch (~19 mm) in one mild steel example.

3) Welding technique

Travel/Work angle: In flat position, travel angle ~5-15°, work angle ~90° for butt joint. In horizontal/vertical/overhead positions adjustments are needed due to gravity.

Gun technique: With slag-producing wires, use a drag (pull) technique—that is, pointing the gun toward the completed weld and dragging backward. One easy rule: “if there’s slag, you drag.”

Multi-pass welds: Ensure slag removal between passes; adjust parameters when welding in vertical/overhead positions (often reduce current/voltage by 10-20% due to gravity effects).

4) Quality and inspection

Visual inspection: Look for full fusion, correct bead shape, minimal undercut, no excessive slag inclusion.

Slag must be removed to allow inspection and finishing.

In critical applications (structural, pressure vessels) welds may need non-destructive testing (NDT) and adherence to designated standards/procedures. For example, certain competency units specify conformance to AS 1554 (Australia) or ABS (American Bureau of Shipping) etc.

VII. FAQ – Frequently Asked Questions

Q1. Is FCAW the same as MIG or GMAW?

No — while FCAW shares similarities with the Gas Metal Arc Welding (GMAW) (often called MIG) process in terms of continuous wire feed, the main difference is that FCAW uses a tubular, flux-filled electrode. The flux (and optionally shielding gas) provides the protection, whereas in MIG the electrode is solid and relies entirely on external shielding gas.

Q2. Can I weld aluminium with FCAW?

In general, no — FCAW is designed for ferrous materials (carbon steel, low alloy steel, some stainless) and the flux-cored wires for aluminium are not common or standardised. Aluminium welding typically uses other processes (GMAW with appropriate shielding gas, GTAW, etc).

Q3. What material thicknesses are suitable for FCAW?

FCAW is well-suited for moderate to thick sections. The self-shielded version is less recommended for very thin material (for example thinner than ~20 gauge) because of higher heat input, slag, and difficulty controlling the weld pool.

Q4. Which shielding gas is used in gas-shielded FCAW?

When an external shielding gas is used, common choices include carbon dioxide (CO₂) or blends of argon and CO₂ (for example 75% Ar / 25% CO₂) in the dual-shield variant.

Q5. Why is slag produced, and do I always have to remove it?

Yes. The flux inside the tubular wire melts and forms slag on top of the weld bead which serves to protect the weld as it solidifies and cools. Before subsequent weld passes (in multi-pass welds) or for final finishing, the slag must be removed to ensure quality and allow inspection.

Q6. What are common defects specific to FCAW and how can I avoid them?

Some common defects include porosity (if gases are trapped in the weld pool or shielding is inadequate), slag inclusion, lack of fusion, undercut or improper penetration. Avoidance means: proper wire feed & polarity, correct stick-out, clean base metal, consistent travel speed, correct shielding (or flux health in self-shielded version), and appropriate technique.

Q7. Is FCAW harder to learn than other welding processes?

It depends. Compared to manual stick (SMAW) or TIG (GTAW) processes, FCAW may be more forgiving in certain conditions (especially self-shielded outdoors) but still demands correct parameter setup, wire feeding, and good technique. So while it may have a “lay-up” advantage, achieving high quality welds (especially in critical applications) still needs skill and practice.

Conclusion

FCAW is a flexible, high-productivity arc welding process using a flux-filled tubular electrode, often with continuous wire feed and usually constant-voltage.

Two main flavours: self-shielded (no external gas) and gas/dual-shielded (external gas + flux).

The process offers strong advantages for outdoor, structural, thick-section and positional welding, due to high deposition and robust shielding options.

But it also has limitations: slag removal is required, more fume/smoke, higher consumable cost, and less suitability for thin-gauge or aesthetic welds.

Understanding joint preparation, equipment setup, technique and proper parameter control is critical for weld quality.

For industrial buyers, procurement managers and engineers: matching the correct wire type (self vs gas-shielded), machine capability (wire feed system, polarity, voltage range), and application (material thickness, position, environment) is crucial for achieving cost-effective and quality welds.

Related articles:

1. What is GMAW (MIG Welding) & How Does it Work?

2. The Ultimate Guide to TIG Welding: Mastering the Basics and Beyond

3. An In-depth Guide to Submerged Arc Welding (SAW) & Its Industrial Applications

4. How Does A Laser Welding Machine Work?

5. How MMA Welding (SMAW) Drives Modern Manufacturing: A Complete Guide

.png)