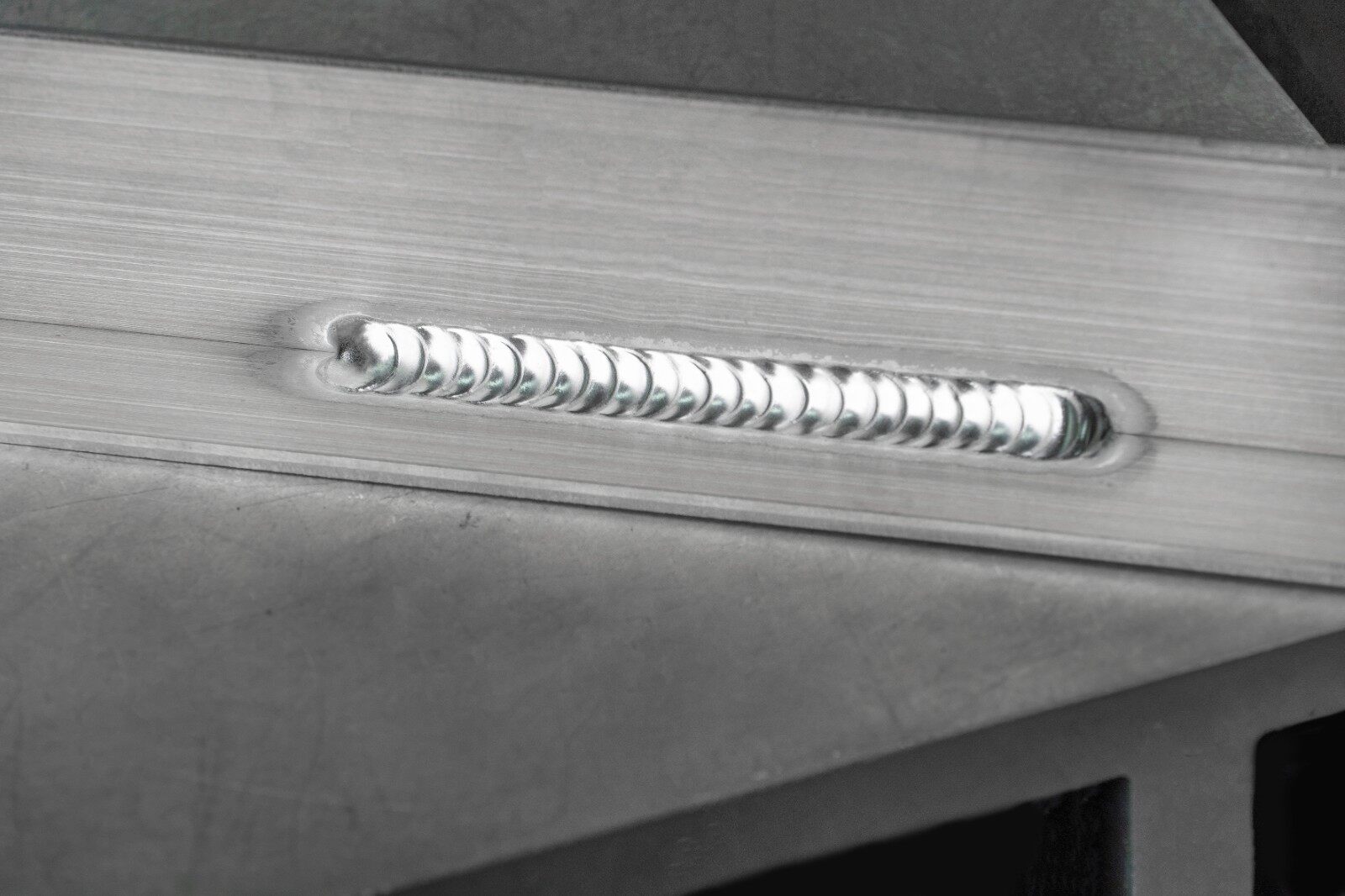

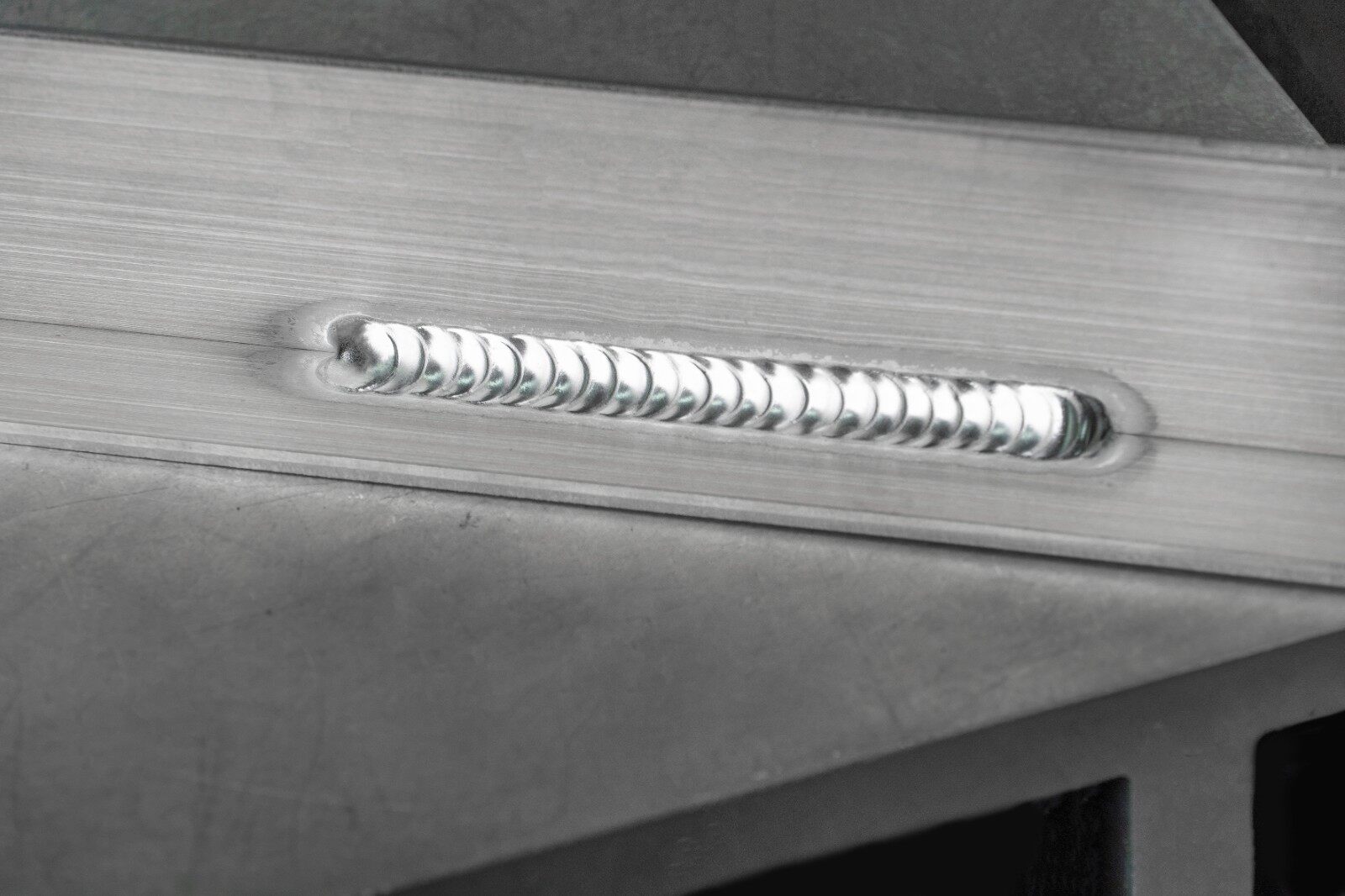

Tungsten Inert Gas (TIG) welding, formally known as GTAW (Gas Tungsten Arc Welding), is the definitive process for achieving strong, clean, and aesthetically superior joints on thin sheet metal. While the process offers unparalleled control, working with materials under 3mm (1/8 inch) is an unforgiving task where a fraction of a second can lead to disastrous warping or burn-through.

Mastering sheet metal TIG welding requires meticulous preparation, precise machine settings, and a consistent hand. This guide provides an in-depth, structured approach to mastering the TIG process specifically for thin gauge materials, ensuring your welds are strong, clean, and distortion-free.

I. What Is TIG Welding and Why It Is Ideal for Sheet Metal?

TIG welding uses a non-consumable tungsten electrode to create the arc that melts the base metal. The molten area, known as the weld puddle, is protected from atmospheric contamination by a steady flow of inert shielding gas, typically pure Argon. The operator adds a separate filler rod manually to the weld puddle.

1) The Thermal Challenge of Sheet Metal:

Thin sheet metal has very little thermal mass—it cannot absorb or dissipate the intense heat from the arc effectively. This means heat rapidly builds up, leading to the primary failure modes: warping (distortion) and burn-through.

2) TIG’s Unique Advantages for Thin Gauge:

TIG is the preferred choice for thin metals due to its superior control mechanisms:

Independent Heat and Deposition: Unlike MIG or Stick welding, where adding filler metal inherently requires increased amperage (heat), TIG separates the heat source (torch) and the filler (rod). This allows the welder to control the puddle size with the foot pedal (amperage) and feed the filler rod only when needed, minimizing overall heat input.

Pinpoint Arc Control: TIG allows the tungsten to be ground to a fine point, creating a focused, high-density arc. This concentrates the heat exactly where it’s needed, resulting in a narrow Heat Affected Zone (HAZ) and significantly less material movement.

Low Amperage Stability: Modern TIG inverters are designed to maintain a perfectly stable, smooth arc even at extremely low currents (down to 5–10 amps). This is essential for delicate work on materials like aluminum foil-thin gauge.

Aesthetics: TIG produces welds free of spatter and slag. The resulting bead is clean, requiring minimal post-weld cleanup, which is critical since grinding thin metal removes base material and weakens the part.

II. Tungsten Selection and Preparation

The tungsten electrode is your primary tool. Its material and geometry dictate the arc quality and heat focus.

1) Choosing the Right Tungsten Type:

For almost all sheet metal applications—including mild steel, stainless steel, and chromoly—you should use tungsten designed for DC (Direct Current) welding.

| Tungsten Type | AWS Designation | Tip Color | Ideal Applications | Notes for Sheet Metal |

| 2% Lanthanated | EWLa-2 | Blue | DC and AC, broad range. | Recommended standard. Excellent arc stability, holds a sharp point well at low amps. |

| 1.5% Lanthanated | EWLa-1.5 | Gold | DC and AC, general purpose. | Very similar performance to 2%, great all-rounder. |

| 2% Ceriated | EWCe-2 | Grey | DC, low amperage. | Excellent for starting and holding a point at the absolute lowest amperages. |

2) Selecting Tungsten Diameter:

The size of your tungsten must be matched to the amperage range required for the sheet metal thickness.

Too large a tungsten will lead to an unstable arc at the low amperages needed for thin metal.

Too small a tungsten will overheat and contaminate easily, dulling the point.

For the majority of sheet metal fabrication (0.8mm to 2.5mm thickness), the best choice is 1.6mm (1/16 inch) tungsten. This size provides stability without drawing excessive heat.

3) Grinding and Tip Geometry:

The shape of the tip is critical for focusing the arc and minimizing the HAZ.

Grinding Direction: Always grind the tungsten lengthwise (parallel to the rod). Grinding crosswise creates small grooves that cause the arc to wander and split, resulting in erratic heat.

Tip Geometry (Long Taper): For sheet metal, grind a long, sharp taper (around $2.5 \times$ the diameter). A sharper point creates a concentrated, narrow arc cone, allowing you to pinpoint the heat.

Separate Wheel: Use a grinding wheel designated only for tungsten to avoid contaminating your electrode with steel, aluminum, or other materials.

III. Filler Metal Selection

The filler metal provides the necessary alloy to strengthen the joint and helps bridge minor gaps. For sheet metal, the goal is to introduce the necessary material without cooling the puddle or requiring excess heat.

1) Matching Filler Metal to Base Material:

The filler alloy should match the base material composition.

| Base Metal | Recommended Filler Rod | Notes |

| Mild Steel/Carbon Steel | ER70S-2 or ER70S-6 | S-2 has better deoxidizers; S-6 is more common and often sufficient. |

| Stainless Steel (304) | ER308L | Low-carbon version minimizes sensitization (carbide precipitation). |

| Stainless Steel (316) | ER316L | Used when molybdenum content is required for corrosion resistance. |

| Aluminum (General) | ER4043 | Flows better and has a lower melting point than 5356, making it excellent for thin sheet. |

2) Filler Rod Diameter for Sheet Metal:

The most common error in sheet metal TIG welding is using a filler rod that is too thick. A thick rod acts as a heat sink; when you dab it into the puddle, it pulls so much heat that the surrounding base metal melts before the rod does, often leading to keyholing or burn-through.

The filler rod should generally be thinner than the base metal.

| Sheet Thickness | Recommended Filler Rod Diameter |

| 0.8mm - 1.0mm (approx. 20 gauge) | 0.9mm (.035") or 1.0mm |

| 1.5mm (approx. 16 gauge) | 1.0mm or 1.6mm (1/16") |

| 2.0mm - 3.0mm (approx. 14 - 11 gauge) | 1.6mm (1/16") |

3) Autogenous TIG Welding:

For extremely thin materials (under 0.8mm) or perfect fit-up joints (like outside corners or lap joints), you may consider Autogenous TIG Welding.

Definition: Fusing the edges of the base metal together without adding any external filler rod.

Application: This technique minimizes the introduction of any foreign material, resulting in a very clean, low-profile weld. It requires extremely stable, low amperage and perfectly fitted edges with no gaps.

IV. TIG Welding Machine Settings for Sheet Metal

Precise machine setup is mandatory for controlling the thermal input on thin materials.

1) Amperage Selection:

Your amperage setting dictates the heat and penetration. A common starting guideline for DC TIG on steel is 30 to 40 Amps per millimeter of thickness.

The key is to set your maximum amperage slightly higher than the required welding current (e.g., 60-70 amps for 1.5mm steel). This allows the operator to use the foot pedal to quickly ramp up and initiate a quick puddle, then back off immediately to the working amperage.

| Sheet Thickness | Amperage Range (DC Steel) | Reason |

| 0.8mm | 30 - 45 A | Very low heat required; focus on speed. |

| 1.5mm | 55 - 75 A | Requires quick initiation, but fast travel speed. |

| 3.0mm | 90 - 120 A | Standard thickness; still requires high speed. |

2) Polarity Selection:

DCEN (Direct Current Electrode Negative): Used for mild steel, stainless steel, chromoly, and titanium. This configuration concentrates approximately two-thirds of the heat into the workpiece, providing deeper penetration and a cooler tungsten tip.

AC (Alternating Current): Used exclusively for aluminum and magnesium. The AC cycle alternates between electrode negative (penetration) and electrode positive (cleaning action) to break up the oxide layer that forms on aluminum.

3) Shielding Gas and Flow Rate:

The shielding gas protects the weld puddle and the hot tungsten from oxidation.

Gas Type: 100% Pure Argon is the standard for virtually all sheet metal TIG welding (steel, stainless, aluminum). For more specialized high-speed or heavy-duty work, Argon/Helium mixtures may be used, but Argon is ideal for precision.

Flow Rate: Use a moderate flow rate to maintain laminar (smooth) coverage. Too little flow leads to contamination; too much causes turbulence, which pulls ambient air into the shield.

Recommended Flow: 8 to 15 CFH (Cubic Feet per Hour) or 4 to 7 LPM (Liters per Minute).

Post-Flow: Ensure your machine’s post-flow timer is set correctly (4–8 seconds). This continues the gas shield after the arc has stopped, protecting the extremely hot weld and tungsten as they cool down.

V. Sheet Metal Preparation

Preparation accounts for 50% of TIG welding success, and on sheet metal, it's closer to 90%.

1) Cleaning the Base Metal:

Contaminants—mill scale, rust, oil, grease, paint—will instantly cause porosity (bubbles) and unstable arc characteristics.

Mechanical Cleaning: Grind or wire brush the joint area until the metal is bright and shiny. Clean a minimum of 1 inch on either side of the seam.

Chemical Cleaning: Wipe the entire area down with a solvent like Acetone to remove any lingering oils or grinding dust.

2) Joint Fit-Up and Support:

The goal is a perfect fit with zero gaps.

Zero-Gap Fit: Even a hairline gap will cause the arc to melt the edges away before they can be joined. Use clamps, magnets, or jigs to ensure the edges are flush and tight.

Heat Sinking (Chill Blocks): To prevent burn-through and control warping, place a backing bar made of Copper or Aluminum directly beneath the joint and clamp it firmly. These materials are highly conductive and will wick heat away from the thin metal, keeping it flat.

VI. Tack Welding Thin Sheet Metal

Tack welds are essential to prevent the thin sheets from pulling apart or overlapping once the heat is applied. On sheet metal, tacks must be small, frequent, and fast.

Frequency: Place a small tack weld every 25mm to 50mm (1 to 2 inches) along the joint length.

The "Blast Tack" Technique: Set your machine 10–20 amps higher than your working current. Press the foot pedal fully for a split second (0.5 seconds) to instantly fuse the edges. This uses high energy for an extremely short duration, minimizing the heat spread into the surrounding material.

Warp Control Tacking: For long seams, alternate the placement of tacks. Start in the center, place the next tack near one end, then the next tack near the opposite end, and repeat. This helps distribute the initial shrinkage forces.

VII. FAQs

Q1: Why does my tungsten keep dipping into the puddle?

Q2: What if I burn a hole through the sheet metal?

A: Stop immediately and let the part cool. Place a copper backing plate behind the hole. With the tungsten freshly ground, use the lowest stable amperage and strike the arc on the edge of the hole. Slowly "walk" the puddle toward the center, feeding tiny drops of filler to bridge the gap.

Q3: How can I minimize warping on long, straight seams?

A: Use the Back-Stepping or Skip Welding method. Instead of welding the joint continuously from one end to the other, weld a 1-inch section, skip 2 inches, weld another 1-inch section, and repeat. Once the metal has cooled, go back and fill the gaps. This distributes the heat input and resulting contraction stress.

Q4: Do I need to back purge stainless steel sheet metal?

A: Yes, absolutely. When welding stainless steel, oxygen contamination on the backside causes sugaring (a brittle, rough surface) which destroys the corrosion resistance. You must tape off the backside of the joint and feed pure Argon into the area before and during welding.

Conclusion

TIG welding sheet metal is a rewarding discipline rooted in precision and preparation. Success hinges on a few core principles: Control Heat Input, Ensure Perfect Fit-Up, and Move Fast.

By implementing the right consumables—like the sharp, long-tapered tungsten and the thinner-than-base-metal filler rod—and utilizing advanced techniques like strategic tacking and heat sinking, you gain the control necessary to produce flawless, warp-free joints every time.

For TIG power sources engineered to provide the stable, low-amperage arc characteristics essential for thin-gauge fabrication, explore the Megmeet MetaTIG DC Series.

Related articles:

1. 9 Tips for Welding Thin Gauge Sheet Metal

2. Pulsed Welding Technology Solves Sheet Metal Problems

3. Tips for Welding Sheet Metal With MIG or TIG

4. How To Weld Dissimilar Metals?

5. MetaTIG ACDC HF TIG Welders 315/400/500A