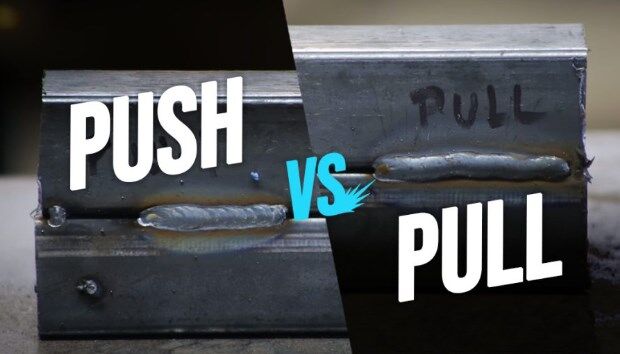

MIG (Metal Inert Gas) welding is one of the industry's most versatile and widely used welding processes. It offers high efficiency, adaptability to various metals, and clean results. However, one common question among welders is whether to push or pull the MIG welding torch. Both techniques have their advantages and disadvantages, and the right choice depends on several factors, including the type of metal, joint thickness, weld position, and desired weld appearance. In this article, we will explore the pros and cons of push vs. pull MIG welding and guide you in choosing the right technique for your specific welding projects.

I. What are the Push and Pull techniques in MIG Welding?

Before diving into the advantages and disadvantages, let’s clarify what pushing and pulling mean in MIG welding:

Pushing: This technique involves tilting the welding torch forward and moving it in the opposite direction of the weld pool. The torch is pushed away from the direction of travel.

Pulling: In this method, the torch is tilted backward and dragged along the direction of the weld pool. The torch is pulled toward the direction of travel.

II. Advantages and Disadvantages of Pushing and Pulling

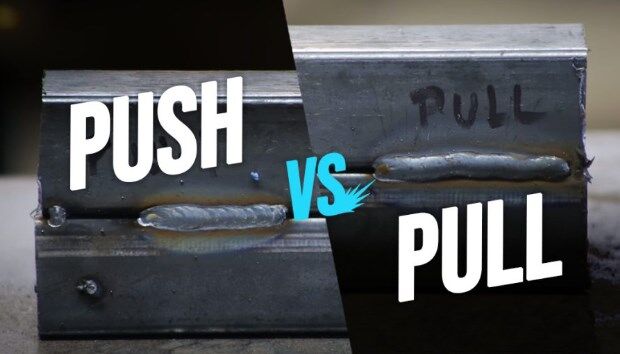

Pushing and pulling mig welding have different effects on the weld pool, the penetration, the bead shape, and the appearance of the weld. Here are some of the pros and cons of each technique:

1. Pushing Technique

1) Advantages:

Flatter and Wider Weld Bead: Pushing creates a wider weld pool, resulting in a smoother and more uniform bead. This is ideal for applications where aesthetics are important.

Better Visibility: The forward tilt of the torch provides a clearer view of the weld pool, making it easier to control the process and avoid defects like porosity or lack of fusion.

Reduced Spatter: Pushing reduces spatter and slag formation because the shielding gas covers the weld pool more effectively.

Suitable for Thin Metals: This technique is ideal for welding thinner materials, such as aluminum, which require less penetration and a broader surface coverage.

2) Disadvantages:

Less Penetration: Pushing provides less penetration into the base metal, making it less suitable for thick materials or applications requiring high strength.

Incompatible with Flux-Cored Wire: Pushing can cause slag inclusions when used with flux-cored wire, as the forward motion traps slag in the weld pool.

2. Pulling Technique

1) Advantages:

Deeper Penetration: Pulling creates a narrower and deeper weld pool, providing greater penetration into the base metal. This is ideal for thick materials and applications requiring high structural integrity.

Stronger Welds: The deeper penetration results in a stronger and more durable weld, suitable for heavy-duty applications.

Ideal for Flux-Cored Wire: Pulling is the recommended technique when using flux-cored wire, as it prevents slag from being trapped in the weld pool. The slag forms behind the weld and can be easily removed after cooling.

Better for Vertical and Overhead Welds: Pulling provides better control over gravity, preventing molten metal from sagging or dripping in vertical and overhead positions.

2) Disadvantages:

Poor Visibility: The backward tilt of the torch can block the welder’s view of the weld pool, increasing the risk of defects.

Increased Spatter: Pulling blows the shielding gas away from the weld pool, leading to more spatter and requiring additional cleaning after welding.

Narrower and Higher Bead: This technique produces a narrower and higher bead, which may not be ideal for applications requiring a smooth, flat surface.

III. How to Choose Between Pushing and Pulling

There is no definitive answer to whether pushing or pulling mig welding is better, as both techniques have their merits and drawbacks. The choice depends on several factors, such as:

1. Type of Metal:

Aluminum and other thin, non-ferrous metals are typically welded using the pushing technique due to their low melting points and the need for surface coverage.

Steel, especially thicker sections, is often welded using the pulling technique for deeper penetration and strength.

2. Type of Wire:

Solid wire is best used with the pushing technique for better gas coverage and reduced spatter.

Flux-cored wire is ideal for the pulling technique as it prevents slag inclusions and offers deeper penetration.

3. Weld Position:

Flat and Horizontal Welds: Both techniques can be used, but pushing is preferred for a smoother appearance.

Vertical and Overhead Welds: Pulling is the better choice for controlling molten metal flow and preventing sagging.

4. Desired Weld Appearance and Strength:

If aesthetics are a priority (e.g., automotive or decorative applications), pushing is preferred for a flatter and smoother bead.

If strength is critical (e.g., construction or heavy machinery), pulling is better for deeper penetration and stronger welds.

IV. Tips for Better MIG Welding Results

Regardless of whether you choose to push or pull, here are some best practices to improve your MIG welding skills:

1. Optimize Your Machine Settings:

Adjust the voltage, amperage, wire feed speed, and gas flow rate according to the type of metal, thickness, and joint design. Use manufacturer recommendations or welding charts to find the optimal settings.

2. Maintain Consistent Torch Technique:

Hold the torch at a consistent angle and distance from the workpiece to ensure even heat distribution and a uniform weld bead.

Avoid excessive weaving or oscillation, as it can lead to uneven results.

3. Prepare the Metal Properly:

Clean the metal thoroughly to remove dirt, rust, oil, or paint. Use a wire brush, grinder, or sandpaper to ensure a clean surface.

Align and clamp the metal securely to prevent gaps or misalignment in the joint.

4. Wear Proper Safety Gear:

Always wear gloves, a welding helmet, goggles, and an apron to protect yourself from sparks, spatter, and radiation. Work in a well-ventilated area to avoid inhaling fumes.

5. Practice, Practice, Practice:

V. Real-World Applications and Case Studies

1. Automotive Industry:

Aluminum body panels are often welded using the pushing technique for a smooth, aesthetically pleasing finish.

Steel chassis components are welded using the pulling technique for maximum strength and durability.

2. Construction:

Structural steel beams are typically welded using the pulling technique for deep penetration and strength.

Decorative metal railings may use the pushing technique for a smooth, flat appearance.

3. Shipbuilding:

Thick steel plates are welded using the pulling technique to ensure deep penetration and withstand harsh marine conditions.

Aluminum superstructures may use the pushing technique for a lightweight and corrosion-resistant finish.

VI. Conclusion

Pushing and pulling are both effective techniques in MIG welding, each with its unique advantages and disadvantages. The right choice depends on the type of metal, wire, weld position, and desired outcome. By understanding the differences and following the tips outlined in this guide, you can optimize your welding process and achieve professional-grade results.

If you want to learn more about MIG welding tips and tricks, you can check out these articles from Megmeet Welding:

MIG Welding Tips From Megmeet: This article provides some useful advice on how to improve your MIG welding skills and avoid common mistakes.

6 Common MIG Weld Patterns: This article explains the different types of MIG weld patterns that you can use to create various shapes and effects on your weld bead.

I hope you enjoyed reading this article and learned something new about push or pull MIG welding. If you have any questions or feedback, please feel free to contact Megmeet Welding Technology.

Related articles:

1. MIG Weld Push or Pull | When to Use Push vs Pull?

2. Push vs. Pull MIG Welding - Which Technique is Right for You?

3. How to Weld Vertical: Tips and Techniques for Various Processes

4. Vertical MIG Welding: Tips, Techniques, and Patterns

5. Pipeline Vertical Welding: A Comprehensive Guide for 2025