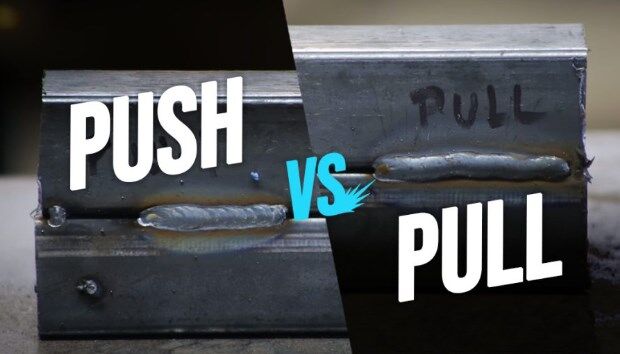

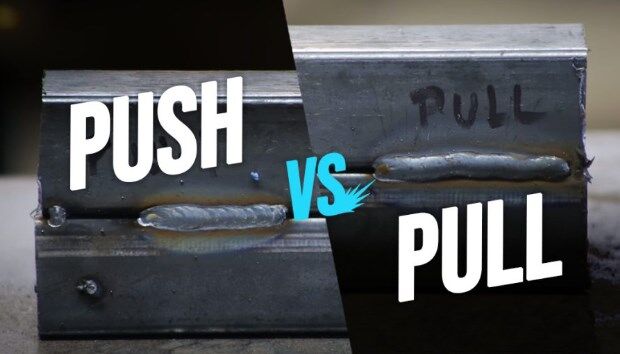

One of the first things a new welder learns—right after how to strike an arc and not to look at the light—is the direction of travel. In MIG welding (GMAW), you are either pushing the torch or pulling it.

Ask ten veteran welders which technique is better, and you’ll likely get ten different answers, five of which might involve a heated argument. The truth is that neither is "better" in a vacuum. Instead, "push" and "pull" are tools in your technical arsenal. Choosing the wrong one can lead to weak penetration, excessive spatter, or a weld that looks like a row of grapes sitting on top of the metal rather than being fused into it.

In this comprehensive guide, we are going to settle the debate. We will look at the physics of the arc, how travel direction changes your weld profile, and exactly when you should use each technique to get professional-grade results.

I. The Basics: What is Pushing and Pulling?

Before we get into the "why," let’s clarify the "what." Both terms refer to the work angle and travel angle of your MIG gun relative to the direction you are moving.

1) The Push Technique (Forehand)

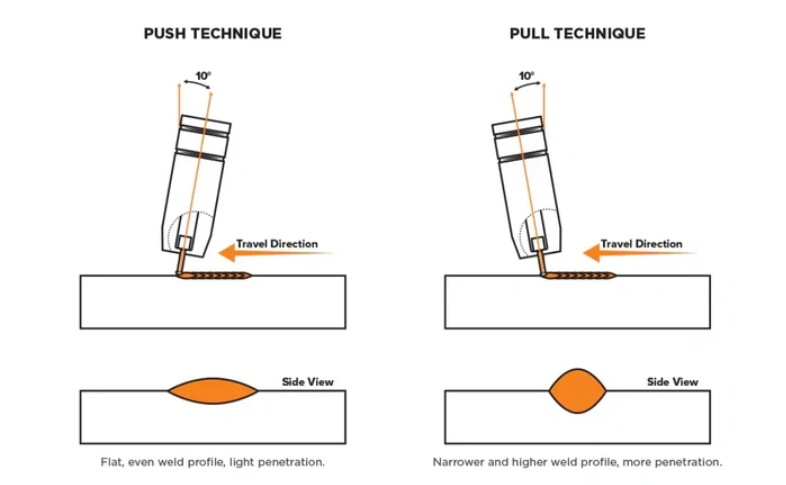

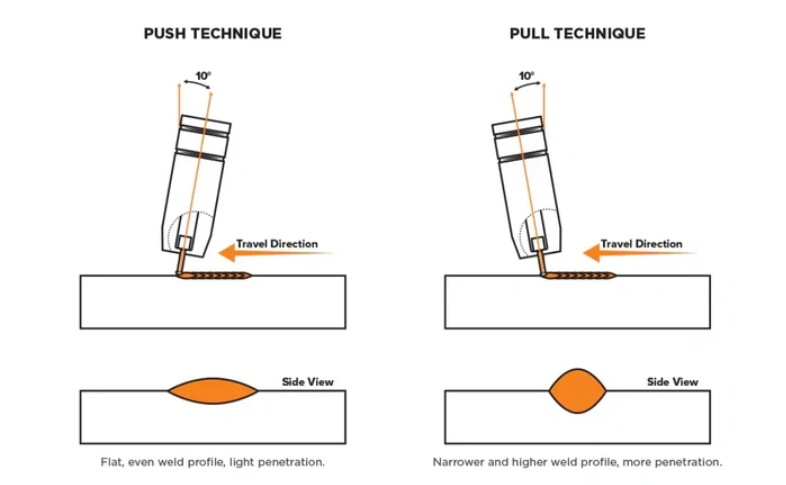

When you use the push technique, you point the MIG gun away from the completed weld bead. You are essentially "pushing" the arc and the gas shield ahead of you into the cold, unwelded joint.

The Movement: If you are right-handed and moving from right to left, the torch is tilted toward the left.

The Visual: You are looking at the "leading edge" of the weld puddle.

2) The Pull Technique (Backhand or Drag)

The pull technique, often called the "drag" technique, is the opposite. You point the MIG gun toward the weld bead you have already laid down. You are "dragging" the arc along the joint.

The Movement: If you are right-handed and moving from right to left, the torch is tilted back toward the right.

The Visual: You are looking at the arc as it sits on the "trailing edge" of the puddle.

II. How Travel Direction Affects Your Weld?

The direction you move doesn't just change your view; it changes how the heat is distributed and how the filler metal is deposited. This is due to the arc force.

1) Penetration Depth:

This is the most significant difference.

Pulling creates deeper penetration. When you drag the torch, the arc is directed straight into the base metal at the bottom of the joint. The heat is concentrated in a narrower area, punching deeper into the steel.

Pushing creates shallower penetration. Because the arc is pointing ahead, some of the arc force is "cushioned" by the weld puddle itself. The heat is spread out over a wider area.

2) Bead Width and Profile:

Pushing produces a flatter and wider bead. This is often preferred for aesthetic reasons on flat surfaces because it requires less grinding and looks "smoother."

Pulling produces a narrower and taller bead (higher reinforcement). Because the metal is being deposited into a more concentrated heat zone, it tends to "stack" higher.

3) Visibility:

Visibility is purely subjective but highly important.

Many welders prefer pulling because they have a clear view of the arc and the joint ahead. The torch isn't blocking the "path."

When pushing, the nozzle and your hand can sometimes obstruct your view of the joint, forcing you to lean over more to see where you are going.

III. The Golden Rule: "If it's Slag, You Drag"

If you’ve spent any time around old-school welders, you’ve heard this rhyme. It refers to processes that use flux to protect the weld, such as Stick (SMAW) or Flux-Cored (FCAW) welding.

In these processes, the melting flux creates a layer of liquid "slag" on top of the weld. If you push the torch, you run the risk of pushing that liquid slag underneath the arc. This traps the slag inside the metal, leading to a defect called "slag inclusion."

However, MIG welding (with solid wire and gas) has no slag. This means you have the freedom to push or pull based on the thickness of the metal and the position of the weld.

IV. When Should You Use the Push Technique?

Pushing is generally the default choice for modern MIG welding, especially in industrial manufacturing and automotive work.

1) Thin Materials (Sheet Metal)

If you are welding 22-gauge to 14-gauge steel, your biggest enemy is burn-through. Since pushing provides a wider, shallower bead with less concentrated heat, it is the safest way to join thin sheets without blowing a hole in them.

2) Aluminum Welding

You should almost always push aluminum. Aluminum has a heavy oxide layer on its surface that needs to be "cleaned" by the arc. When you push, the shielding gas and the arc force hit the metal before the puddle gets there, helping to clean the surface and prevent porosity. If you drag on aluminum, the weld will often come out black, sooty, and structurally weak.

3) Vertical-Up Welding

When welding a joint from the bottom to the top (vertical-up), you are essentially pushing the puddle up the wall. This allows the arc to stay on the leading edge of the puddle, ensuring fusion into the root of the joint.

V. When Should You Use the Pull (Drag) Technique?

Dragging isn't "wrong," but it is specialized for certain conditions where strength is the only priority.

1) Thick Structural Steel

If you are welding 1/2-inch plate and you need to ensure the weld "bites" deep into the root for maximum strength, dragging is the way to go. The concentrated heat ensures that the two thick pieces of steel actually become one.

2) Gas-Shielded Flux Core (Dual Shield)

Even though this uses a MIG-style gun, it involves slag. As the rule goes: "If it's slag, you drag." Dragging ensures the slag stays behind the arc where it belongs.

3) Cleaning Up "Cold" Welds

If you find that your welds are "cold lapping" (the metal is just sitting on top of the surface without melting in), switching to a drag technique can often help the arc "dig" into the base metal better.

VI. Comparison Table: Push vs. Pull at a Glance

| Feature | Push (Forehand) | Pull (Drag/Backhand) |

| Penetration | Shallow | Deep |

| Bead Shape | Flat and Wide | Narrow and Tall |

| Heat Input | Spread out | Concentrated |

| Spatter | Slightly more | Slightly less |

| Visibility | Puddle focused | Arc/Joint focused |

| Best For | Thin metal, Aluminum | Thick steel, Flux-core |

VII. Factors That Influence Your Choice

Beyond just the direction of travel, two other factors will determine if your weld is a success: Torch Angle and Travel Speed.

1) The 10-to-15 Degree Rule

Whether you are pushing or pulling, you should never tilt your gun too far. The ideal angle is usually 10 to 15 degrees from vertical.

If you tilt too far (say, 45 degrees), your shielding gas will "bounce" off the metal instead of covering the puddle. This leads to porosity (tiny bubbles in the weld).

A steep angle also makes the arc unstable and increases spatter.

2) Travel Speed

If you push too slowly, the puddle will get ahead of the arc, causing "cold lap" where the weld doesn't fuse to the metal.

If you pull too fast, the bead will become very thin and "ropey," failing to provide enough filler metal for a strong joint.

VIII. FAQs: Mastering Your MIG Technique

Q1: Does pushing or pulling create more spatter?

Generally, dragging (pulling) creates slightly less spatter because the arc is more stable when it’s digging into the metal. However, if your machine settings are correct, the difference in spatter between pushing and pulling should be negligible.

Q2: Can I push with Flux-Core wire?

Q3: Which is better for a "beginner"?

Many instructors recommend starting with the push technique. It encourages a better habit of "watching the puddle," and since most modern MIG work is on thinner materials (like 1/8" or 3/16"), pushing is the more versatile skill to master first.

Q4: Is pushing better for "Multi-pass" welds?

When doing multiple layers on thick metal, the first "root pass" is often dragged for maximum penetration. Subsequent "fill" and "cap" passes are often pushed to create a smoother, wider finish that blends into the surrounding metal.

IX. Practical Tips for Better MIG Welds

Check Your Gas Flow: No matter how you move the torch, if your gas flow is too low (below 15 CFH) or too high (above 30 CFH), your weld will be ruined. Aim for 20–25 CFH for most indoor work.

Clean Your Metal: MIG welding does not like rust, oil, or mill scale. Spend five minutes with a flap disc before you weld, and your choice of push vs. pull won't matter nearly as much as the clean fusion you'll get.

The "Stay on the Edge" Trick: Whether pushing or pulling, always keep your arc on the leading 1/3 of the weld puddle. If you get too deep into the center of the puddle, you lose penetration. If you get too far ahead, you'll get burn-through.

Listen to the Sound: A good MIG weld sounds like "sizzling bacon." If it sounds like a series of "pops" or a "hiss," your voltage and wire speed are out of sync with your travel direction.

Conclusion: Use the Right Tool for the Job

In the end, the "Push vs. Pull" debate isn't about which one is right; it’s about understanding the physics of the arc. Use the push technique when you need a smooth finish, when working on thin materials, or when welding aluminum. Use the pull technique when you need maximum penetration on thick structural steel or when working with flux-cored wire.

A professional welder is someone who can switch between these techniques without thinking twice. By mastering both, you ensure that your welds are not only visually appealing but also structurally sound.

Achieving this level of versatility requires a machine that can adapt as quickly as you do. For heavy-duty industrial applications, the power and consistency of the welding source are paramount. Megmeet heavy-duty industrial welding machines are engineered to provide the stable arc and precise wire feed necessary for both pushing and pulling on high-demand projects. Their advanced digital control systems ensure that whether you are seeking the deep penetration of a drag weld or the clean finish of a push weld, the machine maintains the optimal parameters for a flawless finish every time.

Related articles

1. Push or Pull Mig Welding: Which One to Choose?

2. AC vs DC Welding: Which One is Better for TIG Welding?

3. What is an Inverter Welder & How it Works (Top 6 Inverter Welders)

4. Inverter vs Transformer Welders: Which One Reigns Supreme in Welding?

5. Porosity in Welding: Causes, Types, Effects and Solutions