In today's diverse fabrication and manufacturing environments, flexibility and efficiency are paramount. Having a single machine capable of handling multiple welding processes isn't just a convenience; it's a strategic advantage. This is where the concept of the multiprocess welding machine shines, offering the adaptability to tackle different materials, joint types, and repair tasks without changing equipment.

Leading the way in this space is the Megmeet Ehave2 CM Series, a range of industrial intelligent welding machines (available in 350A, 500A, and 630A) designed as All-in-one Welding Machines for a comprehensive suite of welding processes. Let's explore what makes a multiprocess machine so valuable and why the Ehave2 CM Series stands out.

I. What is a Multiprocess Welding Machine?

Simply put, a multiprocess welding machine combines the capabilities of several different welding power sources into one unit. Instead of needing separate machines for MIG, TIG, Stick (MMA), and other processes, a single multiprocess welder can switch between them, saving space, reducing cost, and increasing workflow efficiency.

II. The Megmeet Ehave2 CM Series: A True All-in-One Solution

The Megmeet Ehave2 CM Series takes the multiprocess concept to the next level. It's not just about having multiple processes; it's about having them work together intelligently and reliably. The Ehave2 CM Series supports an impressive range of processes:

CO₂/MAG/MIG Welding: The core of many fabrication tasks. Supports various wire sizes (0.8mm to 1.6mm, with customized 2.0mm and 2.4mm options) and materials, including MAG flux-cored carbon steel and MIG DC stainless steel. Offers Synergic/Separate adjustment for optimal parameter control.

Simple DC TIG Function: For applications requiring precise, high-quality welds, especially on thin to medium plates. Features scratch start/lift-start, extensive parameter settings, and overlapping arc control to reduce tungsten loss and ensure a 100% arc starting success rate.

MMA (Stick) Welding: Essential for welding thicker materials, dealing with less-than-perfect fit-up, and long cable operations. Supports electrodes up to 6.0mm and includes adjustable arc starting current and arc force for optimal performance.

Carbon Arc Gouging: A vital function for quickly preparing joints, cleaning roots, and reworking welds. The 630A model can gouge with carbon rods up to 12mm.

Fast Mode Weld Function: Ideal for speeding up spot welding and short-seam welding applications, boosting productivity.

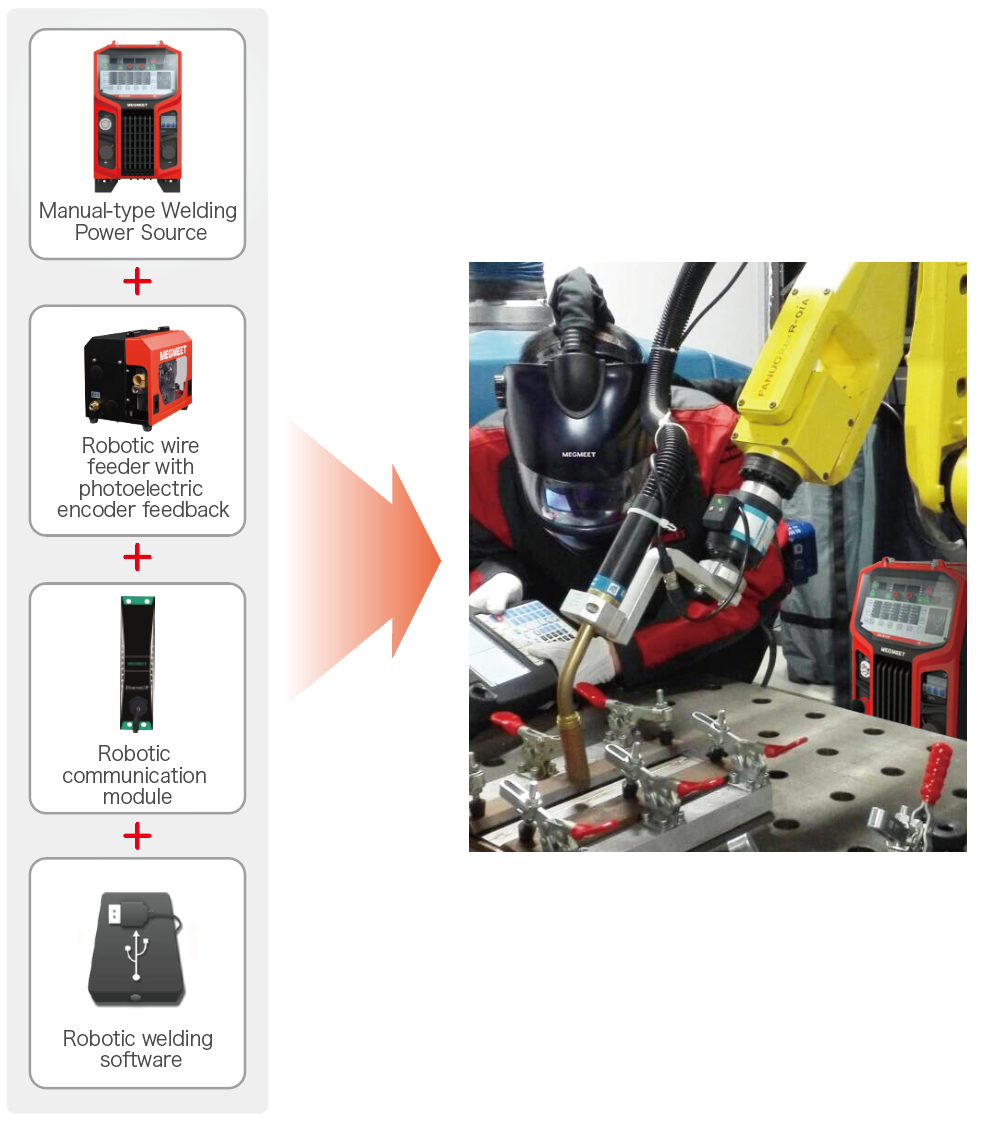

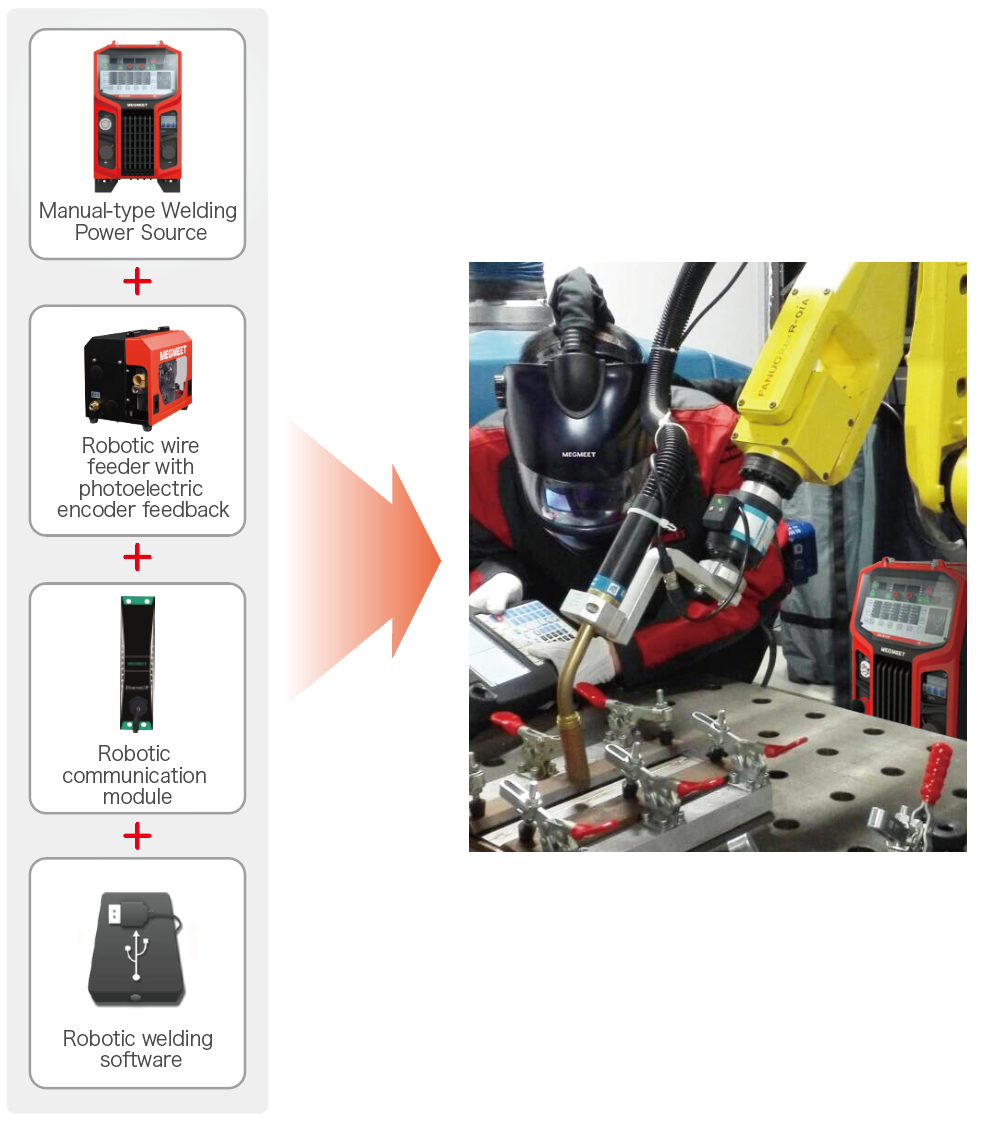

Other Functions: Includes capabilities that can be expanded to a robotic welding power source with the addition of accessories, making it future-proof.

This comprehensive list means that with a Megmeet Ehave2 CM machine, you are equipped for a vast majority of welding tasks in an industrial setting.

III. Engineered for Performance and Reliability

The Ehave2 CM Series isn't just versatile; it's built for demanding industrial use:

Advanced Patented Technologies: Incorporates more than 20 independent patented technologies, such as arc starting soft-transition control and TIG arc ignition energy control, ensuring higher reliability and better performance.

Improved Arc Starting: Droplet cleaning detection and control technology automatically removes the end of the wire before starting, significantly improving arc start success rate and quality.

Stable Long-Cable Welding: Welding voltage and welding current compensation function guarantees the stability of welding even with long cables (up to 50 meters) and ensures that actual values match preset values.

Robust and Durable: With a lightning protection level reaching Class D and a wide-range input voltage, the machines are suitable for severe power grids and can expand to work with generators.

High Duty Cycle: All models feature a 100% rated duty cycle, meaning they can weld continuously at their maximum amperage, essential for heavy-duty, harsh environments.

IV. Smart Features for Modern Fabrication

Beyond core welding performance, the Ehave2 CM Series integrates intelligent features for enhanced management and efficiency:

Extensive Expert Database & Parameter Management: Comes with an extensive expert welding database and offers up to 99 groups of welding parameters storage/calling channels with easy one-key operation, ensuring consistent results and simplifying setup.

WPS Adherence: Current and voltage limiting functions allow setting upper and lower limits, preventing operators from working outside of critical WPS parameters.

Seamless IoT Integration: RFID card-linking function allows for convenient management of machine usage authority and seamless connection with the Megmeet SMARC Smart Welding Cloud System (welding management system). This enables intelligent functions like parameter issuing, welding hours statistics, and critical welding parameter traceability.

Future-Proof and Upgradable: A U-Disk interface ensures customers can easily obtain Megmeet's foremost welding programs and customize functions via a simple USB upgrade. The potential to expand to a robotic welding power source adds significant long-term value.

V. Energy Efficiency: Saving Costs and Reducing Impact

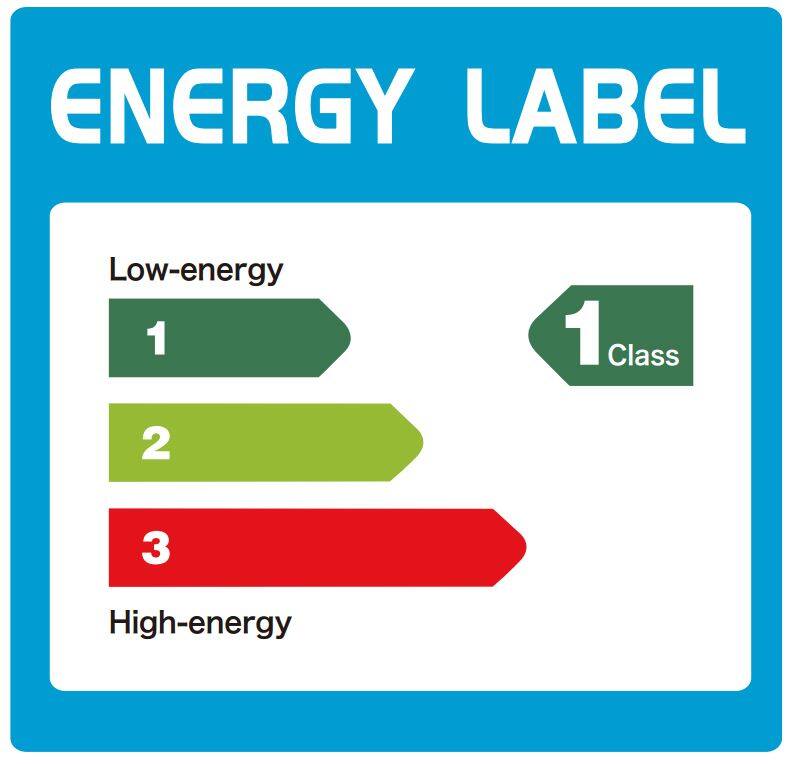

Inverter technology in the Ehave2 CM Series ensures first-class energy efficiency, meeting the national standard. This translates directly into significant electricity cost savings (estimated 3 kWh/day compared to other inverter welders working 4 hours a day at 300A) and a reduction in carbon emissions.

Conclusion: The Smart Choice for Versatility

The Megmeet Ehave2 CM Series multiprocess welding machines are more than just a collection of functions in one box. They represent a sophisticated, reliable, and intelligent solution for a wide range of industrial applications. Their ability to seamlessly switch between CO2/MAG/MIG, TIG, MMA, Arc Gouging, and Fast Weld processes, combined with advanced control technologies, robust build, smart features like IoT connectivity and parameter management, and impressive energy efficiency, makes them an indispensable tool for modern fabrication.

For businesses looking to consolidate equipment, increase flexibility, improve weld quality, enhance data traceability, and boost overall productivity in demanding industrial environments, the Megmeet Ehave2 CM Series is a compelling and powerful choice.

Unlock the full potential of your welding projects with the Megmeet Ehave-2 CM Series. Contact Megmeet Welding Technology today to experience the future of welding. For the latest welding tips, industry insights, and updates, visit the Megmeet-welding News Center or follow us on LinkedIn.

FAQs:

1. What welding processes does the Megmeet Ehave-2 CM Series support?

It supports MIG/MAG, TIG, MMA, FCAW, and more.

2. Is the Megmeet Ehave-2 CM Series suitable for aluminum welding?

3. What is the duty cycle of the Megmeet Ehave-2 CM Series?

4. Does the Megmeet Ehave-2 CM Series have safety protection features?

Yes, it includes input over/under voltage protection, phase loss protection, overheat protection, and short circuit protection.

Related articles:

1. Choosing the Best All-in-One Welder for Your Needs

2. All in One Welder: What Is It and Why You Need One

3. 7 Best Multi-Process Welders of 2023 – Reviews & Top Picks

4. 【New Product】Ehave-2 CM Multi-process Welding Machines

5. MIG/TIG/Stick Multi-Process Welders for Sale – Ehave2 CM