Welding shops today need machines that do more than one job well. Ehave2 CM Series Multi-process Industrial Intelligent Welders 350/500/630A from Megmeet is designed exactly for that: one power source that handles MIG, TIG and stick welding for fabrication shops, maintenance teams and industrial production. Below you’ll find an engineer-friendly, easy-to-read breakdown of what multi-process welders are, where the Ehave2 CM Series shines, what to watch for, and practical FAQs buyers actually ask.

I. What is a Multi-process Welder — and Why does it Matter?

A multi-process welder combines multiple welding methods (commonly MIG/GMAW, TIG/GTAW and stick/MMA) in a single power source so you can switch between processes without buying separate machines. That flexibility reduces floor space, lowers capital costs over time, and helps mixed-workload shops move faster between jobs. Modern multi-process systems also include digital controls, pre-programmed parameters and automation interfaces to improve repeatability and throughput.

II. Why Multi-process Welder Matters in Industrial Context

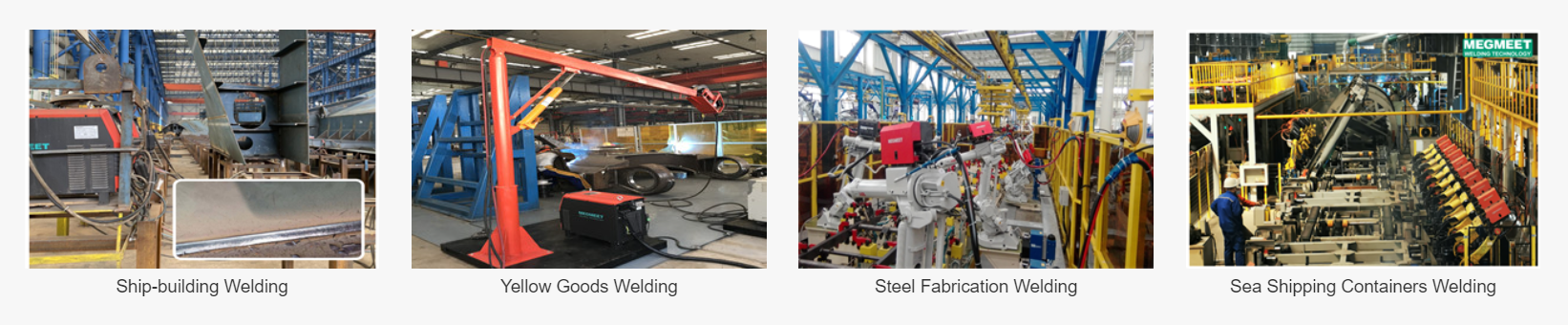

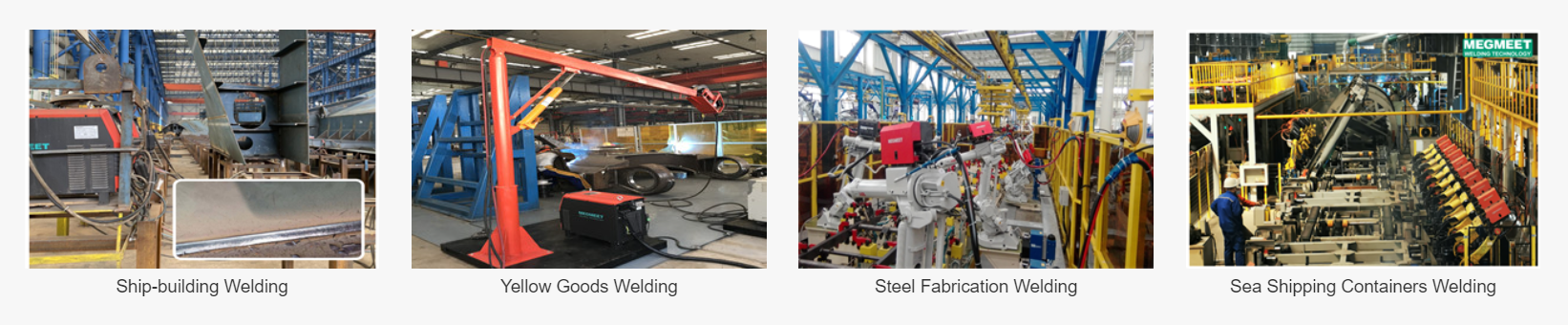

In fabrication, maintenance, ship-building or structural welding environments you may have a mix of tasks: high-speed MIG on carbon steel, precise TIG on stainless or thin plate, stick welding for field repairs, and gouging for weld preparation or rework. Typical single-process machines force you to allocate separate units; a multi-process system gives you one machine capable of handling most jobs. Buyer-guides emphasise that these systems become a strong value when they deliver robust arc control, industrial duty cycles and automation-friendly features (see general industry advice).

III. What to demand from a serious industrial multi-process machine

When you evaluate such machines for factory or heavy fabrication use, key criteria include:

Full process support (MIG, MAG, TIG, MMA) plus optional modes (gouging, fast-weld)

Strong arc quality: synergic/pulse control, droplet transfer stability

High duty cycle (ideally 100%) for continuous production

Long-cable capability and stable operation under electrical variation

Digital parameter management and repeatability (databases, job recall)

Service/support/spares for long-term operation

IV. Meet the Ehave2 CM Series – Features & Highlights

Megmeet positions the Ehave2 CM Series as an industrial intelligent multi-process family (available in 350A / 500A / 630A variants) built for production environments. Here are the features that matter day-to-day:

True multi-process capability. The unit supports MIG, TIG and stick welding, so single-workshops and mixed-process production lines can run one power source for varied jobs.

Advanced arc control (droplet necking detection). The Ehave2 CM includes droplet necking detection to improve arc starts and transfer stability — that reduces spatter and improves first-pass results on robotic or manual welding.

Large welding parameter database. Factory presets plus up to 99 programmable parameter groups make repeatable setups and process handovers quick — useful for shift work and complex part families.

Robust protection & reliability. Input over/under voltage protection, phase loss safeguards and limiting functions protect the power electronics in unstable supply environments. Megmeet promotes long-term duty and lightning protection for harsh shop conditions.

Industrial duty cycle. Models in this family are dimensioned for long runs and heavy jobs — look for higher duty-cycle ratings (e.g., 100% duty cycle options on certain configurations) when evaluating for production use.

These combined features make the Ehave2 CM Series a sensible choice when you need a single, durable unit that handles a range of welding tasks reliably.

V. Typical use cases of the Ehave2 CM Series – who benefits most?

Fabrication shops that build small to mid-size assemblies and need MIG for speed, TIG for precision and stick for field repairs.

Maintenance teams that must perform on-site steel repairs with different electrodes and gas setups.

Light production lines that mix manual and automated cells and need a standardised power source across stations.

Training facilities where students learn multiple processes on the same machine.

If your primary work is one process and it’s extremely heavy duty (e.g., full production SAW or continuous robotic MIG in a high-throughput plant), a dedicated single-process system may still make sense — but for many shops the flexibility wins out.

VI. How the Ehave2 CM Series stacks up — practical comparison point

When comparing multi-process systems, focus on these measurable items:

Arc control options — synergic curves, pulse modes, arc compensation and droplet transfer control. Ehave2’s droplet necking feature helps here.

Duty cycle & current range — choose the model (350/500/630A) that matches your typical weld thickness and continuous runtime. Megmeet lists several frame sizes for different workloads.

Wire feed and feeder integration — robust feeders and remote feed (SuperSnake-style extensions on some systems in the market) expand reach for automation. Check feeder compatibility and options.

Digital features & documentation — welding databases, parameter locking, and connectivity to quality tracking systems matter for traceability and repeatability. Ehave2 provides a programmable welding database.

Service & spare-parts availability — industrial users should verify local support, consumable supply and firmware/service tools before purchase. General industry guides recommend this as a buying priority.

VII. Installation, maintenance and tips for long life

Install on a stable, well-ventilated surface and protect from direct water and heavy dust.

Keep wire-feeder internals clean and check drive rolls and liners regularly.

Use recommended shielding gas mixes and wire types for the process; wrong gas/wire pairing is a common source of poor weld quality.

Verify supply voltage stability; advanced protections in the Ehave2 help, but unstable supplies shorten component life.

VIII. Buying checklist — what to ask your supplier

Which Ehave2 CM model fits my plate thickness and duty cycle? (350/500/630A options)

What wire feeders and torches are included or optional?

Can parameter groups be locked to prevent accidental changes? (Yes — parameter programming is supported.)

Is there remote control/automation interface for robot integration?

What local support, spare parts and warranty terms are available?

IX. FAQs (short, practical answers)

Q: Can I switch between MIG, TIG and stick mid-shift?

A: Yes — multi-process systems like the Ehave2 are designed for that. Switching may require changing torch/torch leads, shielding gas and consumable type, but the power source handles the electrical changes.

Q: Are multi-process welders slower or less reliable than single-process machines?

A: Older all-in-one machines had compromises, but modern industrial systems offer robust arc control and duty cycles comparable to single-process units for most applications. For extreme continuous production, dedicated machines still have an edge.

Q: Do I need special training to use the Ehave2 CM?

A: Basic welding skills are required for each process. The Ehave2’s preset database and programmable groups reduce setup time, but operators still need process knowledge for best results.

Q: Can these machines connect to factory quality tracking or logging systems?

A: Many modern systems include digital connectivity or support external data logging. Confirm the exact interface options for traceability needs.

Q: How do I decide between the 350/500/630A models?

A: Match the maximum continuous welding current and duty cycle to your thickest welds and longest continuous weld times. If you regularly weld thick plate or run long seams, choose a higher-rated model.

Conclusion

Multi-process welders like the Ehave2 CM Series give small and medium workshops professional flexibility: fewer machines to maintain, faster job changeovers and consistent presets for repeatable quality. For industrial users the deciding factors will be duty cycle, local service and integration capability. Compare specifications (arc modes, current range, duty cycle, feeder options) and, if possible, run a weld test using your actual materials before committing to a production purchase.

By choosing Megmeet, you’re not just investing in a machine—you're investing in a legacy of quality, innovation, and performance.

Ready to unlock the future of welding? Explore the Ehave2 CM series today and discover how it can transform your welding operations.

Related articles:

1. Multiprocess Welder with AC TIG -- Benefits, Features and Models

2. Top 10 Multiprocess Welders Recommended by Industry Experts

3. Latest welders features: intelligent, high efficiency, multi-functional

4. Multi-Process Welder Unlocks Efficiency and Versatility

5. 7 Best Multi-Process Welders of 2023 – Reviews & Top Picks

6. Megmeet 2nd Training on Electrical and After-sales Service

7. Megmeet Certificate inquiry