In today’s industrial landscape, businesses need welding equipment that can adapt. Rather than investing in separate machines for MIG, TIG, and stick welding, a multi-process welder combines several welding capabilities in one unit. This versatility offers streamlined workflow, fewer machines to maintain, and better utilization of floor space.

Whether you assemble sheet metal, fabricate structural parts or carry out repair work, picking the right multi-process welder is a strategic decision. This article will walk through the key criteria to compare machines, highlight what features matter most, and offer guidance on how to evaluate your choices. At the end there are FAQs to answer common questions.

I. Why choose a multi-process welder?

Businesses increasingly favour multi-process machines for several good reasons:

Flexibility: One machine handles more than one welding method (for example MIG, TIG, stick, flux-cored). That means fewer separate units and faster switching between processes.

Cost & space efficiency: Purchasing and maintaining one machine instead of two or three reduces capital and service costs, and frees up workshop space.

Training and workflow simplicity: Operators only have to learn one interface or control set, instead of being proficient on multiple distinct machines.

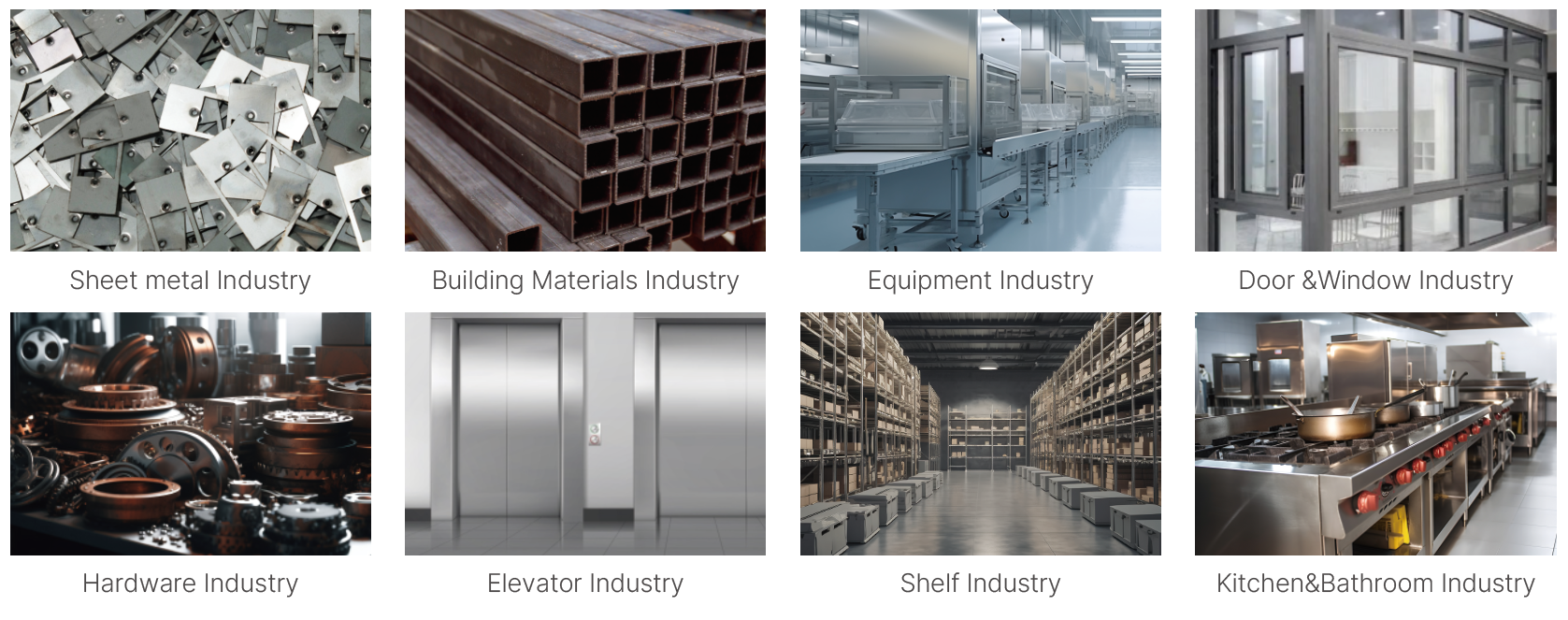

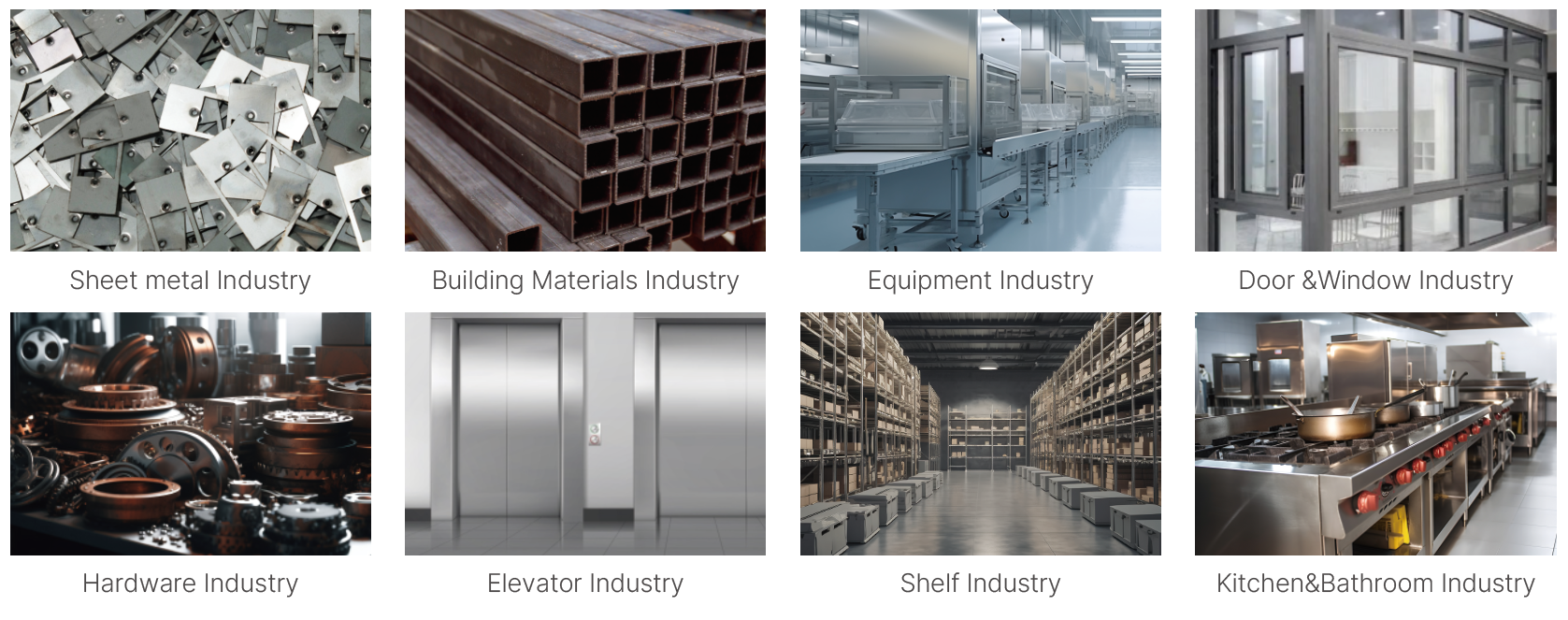

Adaptability: Especially for businesses that weld different materials (steel, stainless, aluminium) or handle varied projects, a multi-process unit supports varied job types without buying dedicated machines for each.

For these reasons, in fabrication shops, maintenance workshops and mobile/field welding units, multi-process welders are becoming a go-to choice.

II. Key criteria for selecting a multi-process welder

When choosing a machine for business use, you ought to compare machines on several technical criteria. Below are the major factors.

1. Welding processes supported

A true multi-process welder will enable you to switch among methods such as:

MIG (Metal Inert / Gas or sometimes gas-less)

TIG (Tungsten Inert Gas)

Stick (Shielded Metal Arc)

Flux-cored (self-shielded or gas-shielded)

Make sure the machine supports the specific combinations you need in your workflow (for example, if you weld aluminium you’ll likely need TIG or specialised MIG).

2. Material types and thickness range

Assess what metals and thicknesses your business commonly welds:

Steel, stainless steel, aluminium, etc.

The thickness of material drives the required current/amperage range. For example, thicker materials need more output capacity.

You’ll want a machine whose output range covers your typical jobs — not only the minimum but the upper end.

3. Power supply and input compatibility

Consider where you will install or use the machine:

Does your shop supply single-phase or three-phase power? What voltage is available?

If you need portability or field work, can the machine handle lower voltage or inverter technology?

Duty cycle: how long you can weld at a given amperage before requiring a cooldown. This affects productivity.

4. Duty cycle and productivity

Especially for business environments, one moment to check:

The duty cycle specification indicates how long you can weld before thermal overload protection kicks in (commonly expressed as % of 10 min interval).

A machine with a poor duty cycle at the amperage you use will force more downtime and reduce throughput.

Always check duty cycle at the current you expect to run, not only at the machine’s maximum rating.

5. User interface, controls & features

Ease of operation translates into faster setup, fewer errors and less training time:

Digital displays, pre-set/synergic programs, intuitive controls help in commercial environments.

Features like spool-gun compatibility (for softer wires or aluminium), gas/gasless switching, and advanced waveform control (for TIG) may be relevant depending on your material mix.

6. Maintenance, serviceability & lifespan

In business usage, uptime matters:

Look for machines with robust cooling, overload protection, accessible consumables and parts.

Evaluate how easy it is to replace wear parts (wire drives, torches, connectors) and whether local service centres exist.

Consider storage and transport if you move machines between jobs—weight, portability, protection matter.

7. Budget and total cost of ownership

Finally, balance upfront cost with long-term value:

A cheaper machine may save money initially but may incur higher consumable costs, lower duty cycle or more downtime.

Factor in training time, maintenance, spare parts, and machine flexibility.

Choose a machine sized right for your business—not excessively over-spec’d (costly) nor under-capable (bottleneck).

III. Top Multi-Process Welder Picks (Business Focus)

While I am not promoting any particular brand names, here are categories of machine-specs you might target for a business environment—use these as benchmarks when you search or request quotes.

Category A – General-purpose workshop machine

Supports MIG, TIG (DC) and stick processes

Typical output up to ~200 A (suitable for many steel fabrications)

Dual voltage (e.g., 230 V / 400 V), reasonable duty cycle (~40-60% at 200 A)

Gas/gas-less MIG switch, spool-gun ready for aluminium using MIG

This category suits a workshop that handles steel and stainless fabrication but may not specialise in aluminium or exotic alloys.

Category B – Heavy industrial / multi-material machine

Supports MIG, TIG (AC/DC), stick and flux-cored processes

Output range up to ~300-400 A or more

Three-phase input, high duty cycle (> 60% at high output)

Advanced digital interface, job memory, spool-gun ready, AC waveform control (for aluminium TIG)

Optional features: pulse MIG, mixed AC/DC TIG, automated switching

This category suits jobs where you handle steel, stainless, aluminium and need robust throughput: production fabrication, maintenance fleets, large structural modules.

Category C – Portable field or mobile unit

Compact multi-process unit (MIG/stick or TIG/stick)

Lower amperage (100-150 A) but rugged, inverter-based, lightweight

115 V/230 V auto-switch or even generator compatible

Lower duty cycle acceptable for repair & maintenance work

Useful for mobile services, site maintenance, smaller mobile fabrication units.

Note: When comparing machines from different suppliers, focusing on their “process-support” matrix (which process, material, thickness), duty cycle at working output, and input compatibility will allow you to filter effectively.

IV. How to Evaluate Your Specific Application

To refine selection for your business, work through the following questions:

What materials (and alloys) will you weld most frequently? (e.g., mild steel, stainless, aluminium)

What thickness range do you encounter most often? Is there a ceiling?

Which welding processes are required now and likely in the near future? (Will you need TIG aluminium down the road?)

What is the power supply available where the machine will be used? Grid power, three-phase, generator?

What are your throughput demands? How many welds/day or job changeovers?

What training level do your operators have? Do you need more automation/synergic setups?

What level of portability is required? Will the machine stay in one spot, or move between job sites?

What is your budget, and what is your expected lifetime for the machine (5, 10 years)?

By answering these, you can then assign a “minimum spec” and a “preferred spec” for each key criterion (process, output, duty cycle, interface). This helps you compare suppliers on a fair basis.

V. Maintenance and Best Practices for Multi-Process Machines

Once you select a machine, ensuring long-life and reliable performance is equally important:

Regularly clean the machine: remove dust, spatter, ensure ventilation is not blocked (important for cooling).

Inspect cables, connectors, torches and consumables for wear. Replace before failure.

Store the machine in dry, stable environment; protect from moisture and corrosion.

Follow manufacturer’s calibration/tracking of torch and drive conditions (wire feed, contact tips).

Train operators on switching between processes, setting up parameters correctly to avoid misuse or machine stress.

Monitor duty cycle usage: avoid consistently exceeding rated duty cycle, as this reduces lifespan.

Keep spare parts and consumables on-hand to minimise downtime.

VI. FAQ – Frequently Asked Questions

Q1. Are multi-process welders as good as dedicated single-process machines?

A: Multi-process machines are very good for applications where flexibility matters and you don’t run one process exclusively at high output all day. For highly specialised tasks (e.g., full-time TIG aluminium or very large structural stick welding) a dedicated machine may still have slight edge in performance. However for many businesses the multi-purpose machine offers excellent value without serious compromise.

Q2. Can a multi-process machine weld different base materials like aluminium, stainless, mild steel?

A: Yes—provided the machine supports the necessary processes (e.g., AC TIG for aluminium, appropriate MIG settings, correct shielding gas) and the amperage is sufficient for the thicknesses involved. Always check the machine’s specs for process-material compatibility.

Q3. How important is duty cycle for business use?

A: Very important. The duty cycle tells you how long you can weld at a given amperage before needing to stop. A low duty cycle means more downtime and lower productivity. For high-volume fabrication you’ll want a machine with a duty cycle suited to your working current, not just the maximum rating.

Q4. Do I always need separate shielding gases for different materials/processes?

A: Yes, usually. MIG and TIG processes typically require specific shielding gases depending on the metal and position (for example argon, argon/CO₂ blends, helium mixes). If a machine supports multiple processes/materials, ensure you have the correct gases available and that the machine supports gasless mode if required (for flux-cored).

Q5. How do I future-proof my machine purchase?

A: Choose a machine that not only meets your current needs but has headroom for process upgrades (e.g., ability to add TIG aluminium, spool-gun, higher amperage). Ensure the supplier offers modular options or expansion, good service network, and software/firmware updates.

Conclusion

For businesses that weld a variety of materials and processes, a multi-process welder offers significant advantages: flexibility, cost efficiency, reduced training overhead and streamlined maintenance. However, to fully realise those benefits you must select a machine that meets your demands across process types, material thickness, duty cycle and power-supply compatibility.

By using the structured criteria presented above, procurement managers, engineers and workshop leads can compare machines on technical merit rather than marketing claims. With proper maintenance and operator training, a well-chosen multi-process machine will serve your business reliably and support your production or repair operations for years.

Stay focused on: what you weld, how often, under what conditions—and then match those to the machine specs. That is the foundation of smart equipment investment.

Related articles

1. All in One Welder: What Is It and Why You Need One

2. Discover the Power of Megmeet Ehave-2 CM Welder Series: All-in-One Welding Machine

3. Multi-Process Welder Unlocks Efficiency and Versatility

4. Multiprocess Welder with AC TIG -- Benefits, Features and Models

5. Multipass Welding: What It Is and How to Do It Right?

6. Buying Your First Welder: Practical and Informative Guide