When choosing a welding method for your project, the decision between Laser Welding and TIG Welding is foundational. Laser welding can deliver high speed, precision, and narrow heat-affected zones, while TIG welding remains a gold standard for control, surface finish, and metallurgy. The phrase Laser Welding vs. TIG Welding encapsulates a trade-off: speed versus finesse, automation versus manual control, penetration versus flexibility. In this article, we’ll examine the differences between Laser Welding vs. TIG Welding, compare their strengths and limitations, discuss ideal use cases, and help you choose which method best suits your project.

I. Why Compare Laser Welding and TIG Welding?

Over decades, gas tungsten arc welding (commonly called TIG) has built a reputation for high-quality welds, especially in thin materials or where aesthetics, metallurgical purity, and precision are paramount. However, the rise of modern laser welding—especially fiber lasers and diode-pumped systems—has introduced a compelling alternative, particularly in automated or high-throughput contexts.

Understanding Laser Welding vs. TIG Welding means understanding how each method deposits heat, how material responds, how practical each is under automation, and how the trade-offs play out in a production setting. We’ll break down the technical foundations, compare key metrics, explore real-world application scenarios, and conclude with guidance on which method is “better” for different classes of projects.

II. How do Laser Welding and TIG Welding Work?

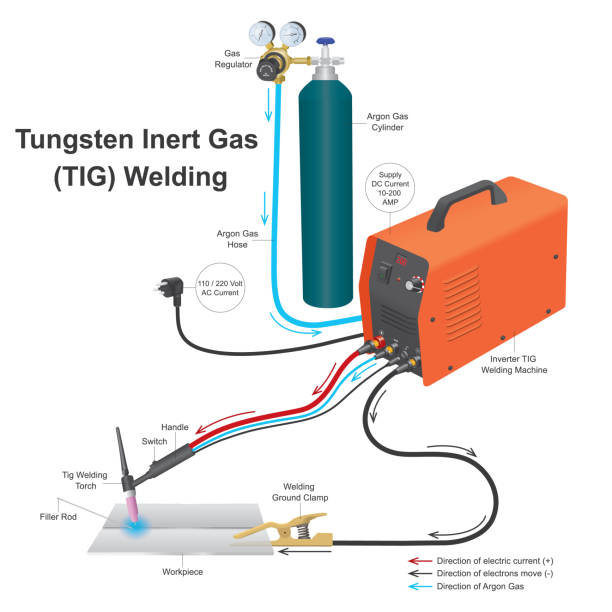

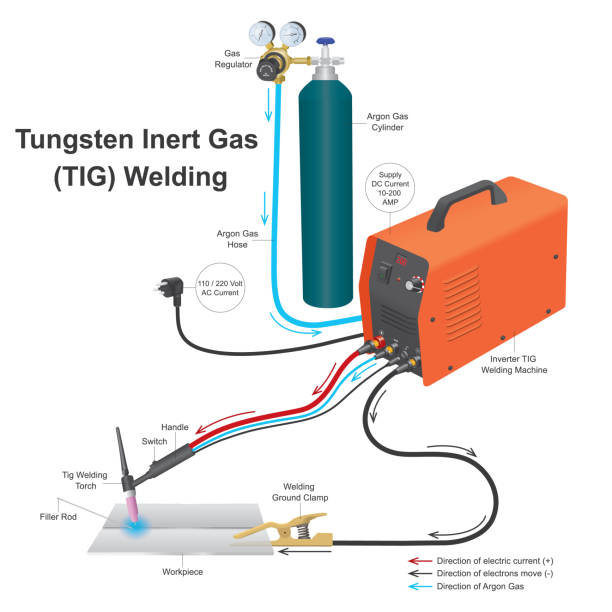

1) What Is TIG Welding?

TIG (Tungsten Inert Gas), also known as GTAW (Gas Tungsten Arc Welding), uses a non-consumable tungsten electrode to create an electric arc between the electrode and the workpiece. The heat generated melts the base metal (and optionally filler wire), while inert gas (often pure argon) shields the weld pool from atmospheric contamination. The operator (or automation) must carefully control arc length, current, filler feed (if used), and travel pace.

TIG welding is prized for:

Fine control of heat input

Clean, high-quality weld surfaces

Ability to weld exotic alloys or thin materials

Flexibility (with or without filler, manual or automated)

However, TIG is relatively slow, demands skilled operators, and can introduce distortion if over-applied.

2) What Is Laser Welding?

Laser welding uses a concentrated beam of light (a laser) to deliver energy to a narrow spot of the workpiece. The intense energy density melts and fuses the adjacent surfaces (sometimes forming a keyhole) to produce a weld. The beam can be continuous, pulsed, or modulated; in some systems, filler wire can be delivered to the melt zone if needed.

Key advantages of laser welding include:

Extremely localized heat input

High welding speed

Capability to automate with precision

Narrow weld seams and minimal post-processing

Because the laser beam is non-contact and can be precisely delivered, it is especially suitable for automated, repeatable processes.

Laser beam welding is widely used in precision industries, automotive, electronics, medical devices, battery modules, and wherever repeatability, throughput, and minimal distortion are required.

III. Comparison: Laser Welding vs. TIG Welding

Below we compare the two processes across critical dimensions.

1) Speed, Throughput & Productivity

One of the most cited distinctions is speed. Laser welding typically achieves much higher welding speeds than TIG welding.

In real-world comparisons, laser welding can be around 4× faster than TIG in many part geometries.

Because laser processing is continuous and highly focused, the bottleneck often shifts from energy delivery to motion kinematics or handling stages.

TIG welding, even when automated, remains slower, especially because of arc initiation, filler handling, and operator adaptation overhead.

In a high-volume environment, the per-weld cycle time advantage of lasers often justifies their higher capital cost.

Thus, when throughput is a priority, laser welding often dominates.

2) Heat Input, Distortion & Heat-Affected Zone (HAZ)

Because lasers concentrate energy in a narrow beam and frequently use high power density, they inherently confine heat penetration.

Laser welding produces lower overall heat input into the part, which reduces warping, distortion, and residual stresses.

The heat-affected zone (HAZ) is narrower, preserving more of the base material's microstructure around the joint.

TIG welding, by contrast, often has a broader HAZ and more thermal spread, which may require post-processing or distortion correction.

The reduced thermal footprint of laser welding is especially beneficial in thin materials, heat-sensitive assemblies, or when close tolerance is critical.

Thus, in applications where warpage or downstream alignment is sensitive, laser welding generally has the upper hand.

3) Weld Quality, Strength & Metallurgy

Quality is central to any welding decision. How do the two processes compare in resulting weld strength, defect rates, and metallurgical soundness?

Because laser welding uses heat more efficiently, less energy is wasted, and less metallurgical damage occurs in adjacent zones.

In controlled studies, laser welds on certain stainless steels have failed in the base metal rather than the weld zone, indicating weld strength comparable or superior to TIG in many use cases.

TIG welding, when performed by an expert, yields excellent metallurgical control, filler fusion, and clean joints—but is more sensitive to operator skill, contamination, and arc consistency.

TIG’s non-consumable electrode means no electrode material is introduced into the weld unless intended; but tungsten inclusion or tip wear can cause contamination or arc instability if not properly managed.

In many routine or high-throughput contexts, laser welding can rival or surpass TIG in joint strength and defect rates, especially when parameters are optimized.

4) Automation & Ease of Deployment

In modern manufacturing, how easily one can automate a welding process often tips the decision.

Laser welding is inherently well-suited to automation: consistent beam delivery, fewer consumables, and minimal operator intervention once parameters are set. Many systems are robot- or cobot-integrated.

Because laser welding has fewer “moving parts” like wire feeds or arc stabilization systems, integration is often easier.

TIG welding automation is more complex: wire feeding, electrode manipulation, arc initiation control, torch angle adaptation, and more. These factors make robotic TIG systems more challenging to calibrate and maintain.

In practice, robotic laser systems are increasingly used in production, especially for thin sheet joining and repetitive welds.

Thus, for scalable, consistent production, laser welding often has a higher “automatable quotient.”

5) Material & Thickness Compatibility

No welding method is universal. Which materials, thickness ranges, or dissimilar joins are feasible?

Laser welding works well on a wide variety of metals: steel, stainless steel, aluminum, titanium, nickel alloys, copper (with higher power), etc.

However, the reflectivity (especially of aluminum, copper) and thermal conductivity of some metals demand more laser power or preheating.

TIG welding is more forgiving on exotic alloys, thin sections, or mixed metals, especially when filler is needed for strength or composition control.

In thicker plate welding, TIG (or other arc methods) may be more practical, as laser power requirements scale and keyhole stability becomes challenging.

So in many thin-to-medium thickness regimes, laser is competitive or better; in heavy thick structures, TIG (or hybrid) may still have advantages.

6) Cost (Capital, Operating, Maintenance)

Cost is always central in engineering trade-offs.

TIG setups have lower initial capital cost than high-power laser welding systems and are well-understood in many fabs.

Operating costs: TIG uses filler wire (often consumable), higher labor due to slower speed, and more operator skill dependence.

Laser systems require higher upfront investment, beam-optic maintenance, alignment, safety systems, and potentially cooling infrastructure.

But in high-volume usage, the cycle time gains, lower labor cost, and lower post-processing can justify the capital.

Maintenance: lasers avoid electrode erosion issues, but require cleanliness, optical alignment, and safety upkeep. TIG systems contend with tungsten wear, electrode handling, and arc stability maintenance.

In short: TIG is cheaper to enter, laser pays off when scale, repetition, or precision justify it.

IV. Use Case Considerations & Selection Strategy

Given the above, how do you choose Laser Welding or TIG Welding for your project? Below are common use-case scenarios and decision guidance.

1) Thin Sheet & High-Volume Production

When you weld thin gauges (e.g. sheet metal assemblies, enclosures) and need consistent high throughput, Laser Welding often outperforms TIG by reducing distortion, accelerating cycle time, and automating the process.

Common in electronics, enclosure manufacturing, battery pack joining, HVAC panelwork, etc.

Because the joint tolerances are controlled in production, the gap sensitivity of lasers is less of a constraint.

2) Custom, Artistic, Small-Batch, or Complex Geometry

If your work is custom, decorative, or made of exotic alloys, TIG Welding may provide more flexibility, control, and adaptability.

The operator can modulate filler, torch angle, and weld path mid-run, something difficult for an automated laser to adjust on the fly.

In art fabrication, sculpture, jewelry, or retrofits, TIG still has strong relevance.

3) Repair, Field Work, Retrofitting

For on-site repair or maintenance, portability and adaptability matter. TIG’s lower infrastructure demand may make it easier to deploy.

Laser systems require optics, beam alignment, and safety enclosure, which may constrain mobility.

4) Mixed Thickness or Heavy Plate Welding

If your design involves thick sections, transitions between thick and thin, or heavy structural welds, TIG (or arc methods) may be more forgiving or practical.

Laser may struggle to maintain keyhole stability or require very high laser power in thick zones.

5) Automation, Robotics, and Long Runs

For long-run production or automated systems, Laser Welding is often more attractive due to ease of parameter repeatability, fewer consumables, and easier robot integration.

In these settings, TIG tends to become the bottleneck.

Thus, the ideal method often emerges from matching project constraints (thickness, volume, geometry, automation readiness) to the process strengths.

V. Summary Table: Laser Welding vs. TIG Welding

| Attribute | Laser Welding | TIG Welding |

|---|

| Speed / Throughput | High (≈ 3–5× TIG in many cases) | Moderate to slow |

| Heat Input / Distortion | Very low, narrow HAZ | Higher, broader HAZ |

| Weld Quality / Strength | Excellent, lower defects | Excellent under expert control |

| Automation Potential | High | Moderate to challenging |

| Tolerance to Gap / Geometry | Sensitive, requires good fit | More forgiving |

| Materials / Thickness | Good across many, thin to medium | Flexible, can support thick and exotic |

| Capital Cost | Higher | Lower |

| Operating Cost | Lower per unit at scale | Higher labor and consumables |

| Maintenance Complexity | Optics, alignment, cleanliness | Tungsten wear, arc stability |

| Best for | High volume, precision, automated production | Custom, small runs, reactive repair, varied geometry |

Conclusion: Which One Is Better?

In the debate of Laser Welding vs. TIG Welding, the answer is not a binary “laser always wins” or “TIG is obsolete.” Rather, the correct choice depends on your project’s requirements in thickness, geometry, throughput, automation, and cost constraints.

If your production demands high throughput, precise control, minimal distortion, and you can enforce tight tolerances, Laser Welding will often deliver a superior ROI.

If your project emphasizes flexibility, manual intervention, complex geometry, or small batch variety, TIG Welding remains a powerful and versatile choice.

Many modern fabricators run both in tandem: TIG for prototyping, repair, or difficult joints; laser for volume runs or repeatable joints.

Related articles

1. Arc Welding vs. Laser Welding: The Key Differences

2. Pulsed vs. CW Laser Welding: Key Differences | Expert Insights

3. Laser Welding vs. TIG (Arc) Welding: Choosing the Best Method for Your Needs

4. Laser Welding vs. MIG Welding: Ultimate Comparison Guide

5. Laser Welding Vs Traditional Welding: Process, Advantages & Applications