Robotic welding is no longer a luxury reserved for high-volume automotive plants. Today, factories of all sizes—metal fabrication shops, machinery manufacturers, home-appliance producers, construction-equipment suppliers, and even small welding workshops—are adopting automated welding systems to improve quality, productivity, and consistency.

But while demand for automation is rising, choosing the right robotic welding system is still overwhelming for many companies. A welding robot is not just a machine; it is a long-term investment that reshapes production workflows, labor allocation, cost structure, and product quality.

This guide breaks down the decision-making process into clear, practical steps so you can confidently select a system that matches your actual welding needs—not just what looks impressive on a catalog.

I. Why Companies Are Moving Toward Robotic Welding

Before selecting a system, it’s important to understand why robotic welding has become such a strong industrial trend:

Higher Weld Consistency: Manual welders vary in technique, speed, torch angles, and fatigue levels. Robots do not. Once programmed, a robot repeats the same movement thousands of times with identical results—critical for industries where weld reliability must be guaranteed.

Better Productivity: A robot can weld faster, for longer hours, and without breaks. Automated systems significantly increase throughput, especially in repetitive, high-volume product lines.

Improved Safety: Robotic welding removes operators from extreme heat, arc flash, fumes, and awkward welding positions.

Reduced Labor Shortages: Skilled welders are harder to find worldwide. Automation allows companies to allocate experienced welders to high-skill tasks while robots handle repetitive jobs.

Lower Production Costs: Although the initial investment is higher, robotic welding reduces scrap, rework, and consumable waste—leading to long-term cost savings.

With these benefits in mind, the next question is simple: How do you choose the right robotic welding system for your factory?

II. The Importance to Choose the Right Robotic Welding System

Selecting a robotic welding system requires more than comparing robot models or reading specification tables. The real challenge is translating your production needs into a system configuration that enhances throughput, quality, and reliability. Many companies invest in automation but fail to achieve expected ROI because they skip this systematic evaluation.

Below is a practical, industry-proven approach used by experienced integrators and manufacturing engineers. Each step addresses a real constraint found in factories—material variation, part geometry, takt-time targets, layout limitations, and long-term scalability.

This step-by-step method ensures you develop a robotic welding strategy that fits your operations today and remains valuable as your production evolves.

III. How to Choose the Right Robotic Welding System: Step-by-Step Guide

1. What Are You Welding? (Material, Thickness, Joints, Variations)

A welding robot cannot perform better than the parts it receives. Understanding your workpiece characteristics dictates everything—from arc modes to robot size, fixture design, and sensor requirements.

1) Material Considerations (deepened)

Robots weld a wide range of metals, but each has specific requirements:

| Material | Considerations |

|---|

| Carbon Steel | Easiest to automate; stable arc characteristics. |

| Stainless Steel | Needs clean surfaces and precise heat input control. |

| Aluminum | Requires stable arc ignition, advanced waveform control, and excellent wire feeding. |

| High-strength alloys | Often require pulsed or special arc modes. |

2) Material Thickness

3) Joint Types

Common joints include butt joints, lap joints, fillet joints, and multi-angle configurations. Complex geometries may require:

4) Workpiece Variation

If every part is identical, selection is easy. If each part varies slightly, you may need:

2. What Production Volume and Cycle Time Do You Need?

Production volume largely determines the type of robotic cell you should invest in.

1) High-volume, mass production

Best choice: Dedicated robotic welding cells

Advantages: highest productivity, lowest unit cost, fully optimized process paths.

2) Medium-volume production

3) Low-volume, high-mix production

If you produce many variations in small quantities, consider:

Cobots and flexible automation solutions allow frequent changeovers without long reprogramming times.

3. What Level of Welding Quality Is Required?

Every industry has different tolerance for weld aesthetics, strength, and repeatability. The welding system must be aligned with your quality expectations.

1) High Structural Integrity Requirements

For automotive components, pressure vessels, pipes, or heavy equipment:

Penetration consistency must be guaranteed

Heat input must remain stable across shifts

Multi-pass routines require precise arc control

Weld data documentation may be mandatory

This is where intelligent digital welding power sources (like Megmeet’s) with advanced waveform algorithms matter.

2) Cosmetic Appearance Requirements

Some applications—stainless products, furniture frames, consumer appliances—prioritize bead appearance:

Pulsed MIG or TIG is often preferred

Low-spatter arc modes

Stable, “soft” arc characteristics

Slow, controlled travel with consistent arc length

3) General Fabrication Requirements

Where welds are functional but not highly cosmetic:

Robust, high-deposition MIG

Reliable wire feeding

Simple, repeatable weld paths

Understanding quality requirements prevents overspending on unnecessary features while ensuring the system meets industry standards.

4. What Level of Automation Fits Your Factory Layout?

Factory layout, floor space, and workflow determine what type of robotic cell you can realistically deploy.

1) Single-Station Cells

Suitable when:

They simplify automation and require minimal integration.

2) Two-Station A/B Cells

The most common choice for medium-volume operations:

3) Positioner-Based Systems

Critical for complex or large parts that require multi-angle welding:

Tilt-rotate positioners align joints with ideal welding angles

Improve penetration and reduce defects

Enable coordinated motion between robot and positioner

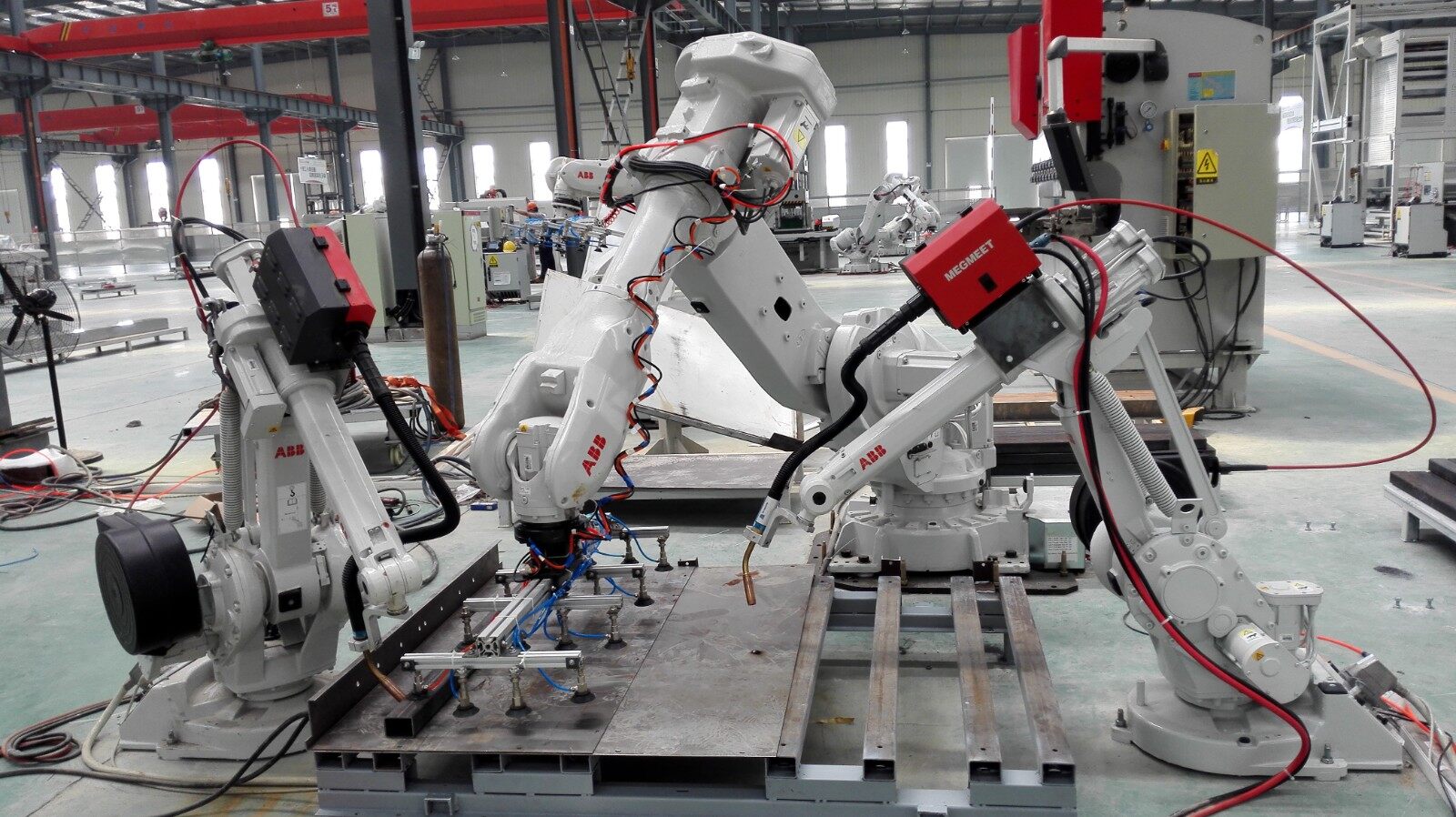

4) Multi-Robot Cells

Useful when:

High deposition rates are required

Large weldments must be completed quickly

Multi-pass welding demands parallel operation

5) Cobot Welding Systems

Ideal for high-mix, low-batch manufacturing:

Choosing the right cell structure ensures your robotic system integrates naturally with your production flow.

IV. What Makes a Good Robotic Welding System? Key Selection Criteria

| Category | What to Evaluate | Why It Matters | What a Good System Looks Like |

|---|

| Welding Performance | Arc stability, penetration, spatter level, waveform control | Determines weld quality, consistency, and rework rate | Stable arc at high speeds, low spatter, adaptive arc modes, strong start/stop performance |

| Power Source Capability | Integration, digital control, pulse processes, multi-material support | Ensures compatibility and optimizes welding parameters | Seamless robot communication, advanced pulse MIG/MAG, aluminum and stainless capability |

| Robot Arm Specifications | Reach, payload, repeatability, mounting options | Affects accessibility, cycle time, and weld accuracy | ±0.02–0.06 mm repeatability, sufficient payload, optimized reach, flexible mounting |

| Torch & Wire Feeding System | Cooling method, neck geometry, wire feed stability | Directly influences arc behavior and uptime | Water-cooled for high duty cycle, push-pull for aluminum, anti-collision protection |

| Fixturing Quality | Positioning accuracy, clamping method, repeatability | Poor fixturing equals poor welds—robots need stable parts | Rigid, heat-resistant fixtures with fast, repeatable clamping |

| Cell Layout & Safety | Space, accessibility, fume extraction, guarding | Ensures safe, efficient operation and reduces downtime | Well-ventilated cell with proper guarding, easy loading, clear operator access |

| Software & Programming | Interface usability, path planning, parameter control | Impacts production setup time and changeover flexibility | Intuitive programming interface, offline simulation support, stable parameter control |

| Adaptability to Part Variation | Seam tracking, touch sensing, adaptive fill | Helps the robot manage inconsistent fit-up | Integrated sensing systems with reliable edge/joint detection |

| Durability & Maintenance | Component lifespan, spare parts availability, service support | Affects long-term cost, uptime, and reliability | Robust design, long torch life, easy access to consumables, responsive technical support |

| Production Efficiency | Cycle time, arc-on time, robot utilization | Determines whether the investment meets ROI | Optimized motion paths, high arc-on time, effective station switching (e.g., dual tables) |

| Automation Compatibility | Connectivity with conveyors, positioners, MES/PLC | Future-proofing for production line integration | Standardized communication protocols, expandable automation interfaces |

| Total Ownership Cost | Energy use, consumables, rework, maintenance | Defines long-term economic viability | Low spatter = fewer consumables, stable arc = reduced rework, efficient power usage |

| Scalability | Ability to add fixtures, new programs, expansion modules | Ensures system can grow with business needs | Modular cell design, flexible programming, future-ready architecture |

V. How to Evaluate a robotic Welding System Supplier

Choosing a reliable supplier is as important as choosing the right robot. Look for companies that offer:

✔ Strong technical support

✔ Local service teams

✔ Training programs

✔ Proven welding process expertise

✔ Long-term spare-part availability

✔ Integration support

✔ Application consultation

A good supplier should help evaluate your parts, recommend fixturing, and optimize welding parameters—not just sell a robot.

Conclusion: Make an Informed Decision

Choosing the right robotic welding system requires more than comparing robot arms—it is a coordinated decision involving process evaluation, fixturing design, power source selection, safety planning, and on-site support. By following a structured, step-by-step approach, companies can significantly reduce risk, improve weld consistency, and unlock substantial productivity gains.

If you need help selecting a robotic welding system or exploring Megmeet-compatible automation solutions, Contact us at https://www.megmeet-welding.com/en/contacts to discover how we can help you achieve superior results.

Related articles:

1. Integration of automated welding and additive manufacturing

2. The future of welding automation: artificial intelligence and machine learning

3. Robotic Welding & Complete Automation Solutions

4. Automatic Welding Machine Basics You Must Know

5. Megmeet - Pioneering Chinese Welding Machines for Precision and Automation