Welding has long been the backbone of vehicle manufacture and repair: it joins metal components to build robust, safe and cost-effective vehicles. In 2025, the demands placed on the automotive industry—lighter weight, mixed materials, higher productivity, electric and hybrid powertrains—mean that welding technology must evolve accordingly.

This guide sets out a clear, accessible overview of modern welding technology in the automotive industry: how it’s used, what processes matter, key material and automation challenges, and what’s coming next.

I. The Role of Welding in Automotive Manufacturing

Welding is essential because the car is a complex assembly of many parts that need to be joined, often in high volumes and to strict quality and safety standards.

1. What welding enables:

Joining sheet-metal body panels (doors, hoods, roofs) into a unified structure.

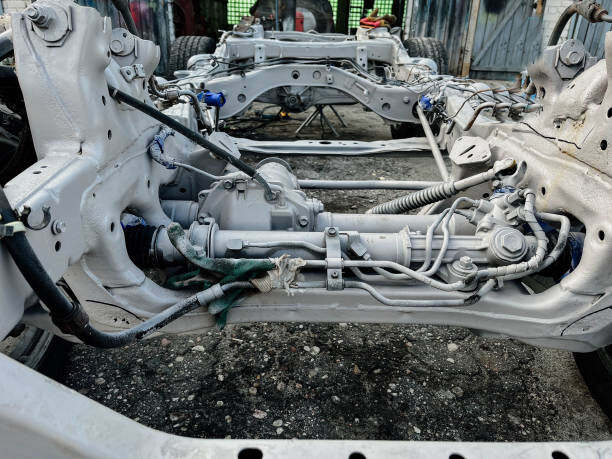

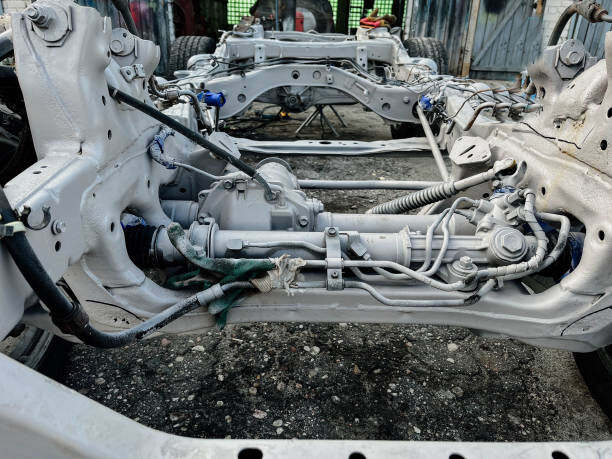

Building chassis and sub-frames that must withstand structural loads, vibration and fatigue.

Joining powertrain and drivetrain components (engine blocks, transmissions, exhaust systems) where weld integrity matters.

Accommodating non-structural elements (interior brackets, seat frames) as well as new systems such as battery trays and electric-vehicle modules.

2. Why welding remains irreplaceable:

Welded bonds can offer continuous, high-strength connections that fasteners (bolts, rivets) can struggle to match.

Welding supports more flexible designs and material choices—such as joining dissimilar metals or thinner metals for lighter weight.

High-volume production demands fast, repeatable joining methods—both in manufacturing and increasingly in repair.

In short: underpinning modern vehicle production and repair, welding technology enables the advances in design, materials and manufacturing efficiency.

II. Key Welding Processes in Modern Vehicle Production

Automotive manufacturers use a variety of welding processes—selected based on material, design, production volume, and repair vs manufacturing environment. Below are the major ones relevant in 2025.

1. Resistance Spot Welding (RSW):

Perhaps the most widely used in vehicle body manufacture, especially for sheet metal joining.

Process: Two electrodes clamp overlapping sheets, an electric current passes, generating heat and forming a nugget joint.

Advantages: Extremely fast (a weld may be completed in under a second), good for coated sheets and high-volume production.

Typical use: Vehicle body “body-in-white” (BIW) sheet-metal assemblies.

2. Gas Metal Arc Welding (GMAW / MIG)

A versatile arc welding method where a continuously-fed wire electrode melts together with the base metal, under inert/active gas protection.

Advantages: High deposition rate, good for many thicknesses, fairly easy to automate.

Uses: Body panels, frames, structural components where speed and flexibility are needed.

3. Gas Tungsten Arc Welding (GTAW / TIG)

A precision arc welding process using a tungsten electrode and shielding gas; often used with a filler rod, sometimes without.

Advantages: Very fine control, strong, clean welds; suitable for non-ferrous metals (e.g., aluminium, magnesium).

Uses: Critical structural parts, repair work, thin sections requiring aesthetic/quality finish.

4. Laser Welding

A high-precision fusion welding method using focused laser beams to join metals.

Advantages: Minimal heat input, narrow welds, fast cycle times, less distortion.

Uses: Sensitive or precision components (battery modules, electronic housings), tailored blank welding, mixed-material structures.

5. Friction Stir Welding (FSW)

A solid-state joining process: a rotating tool produces frictional heat, plasticizing the materials and forging them without reaching melting temperature.

Advantages: Excellent for aluminium and other lightweight alloys, minimal defects, low distortion, environmentally friendly (no filler, no shielding gas).

Uses: Lightweight vehicle structures, aluminium doors/hoods/trunks, electric-vehicle battery trays.

6. Hybrid Welding

Combines two or more processes (e.g., laser + arc) to exploit complementary strengths.

Example: Laser-assisted arc welding gives high penetration, speed, gap-bridging capability.

Use: Thicker autobody panels, complex assemblies where a single method falls short.

III. Material Challenges & Joining Innovations

Modern vehicles increasingly use lightweight materials, mixed-material assemblies, and structural complexity. That raises new welding challenges.

1. Lightweight & Mixed Materials

Automakers are under pressure to reduce vehicle weight (for fuel efficiency or electric range) and yet maintain crash safety. This means more aluminium, magnesium, high-strength steels, and dissimilar material joints.

Traditional fusion welding methods may struggle: higher heat input, distortion, metallurgical defects, difficulty with dissimilar metals.

2. Solid-State Joining Gains Ground

Solid-state methods such as FSW (and its variant FSSW—friction stir spot welding) are increasingly used for challenging joints. For example:

FSSW is gaining popularity for aluminium alloys due to reduced defects and better joint integrity.

FSW allows aluminium-aluminium, aluminium-copper, or aluminium-steel joints with lower distortion and better fatigue life.

3. Advanced Steels & High Strength Materials

High-strength steel (HSS) and ultra-high-strength steel (UHSS) are common in safety-critical vehicle structures. Welding these demands precision and minimal metallurgical damage. RSW, laser and hybrid methods are key here.

4. Repair and After-market Considerations

In the repair sector, welding technology must adapt to mixed-material panels and complicated joint types (e.g., bonded + riveted + welded assemblies). Knowledge of material compatibility and correct welding method is vital.

IV. Automation, Digitalisation & Quality Assurance

In 2025, welding in automotive manufacture isn’t just about heat and metal—it’s about integration with automation, real-time monitoring and digitalisation.

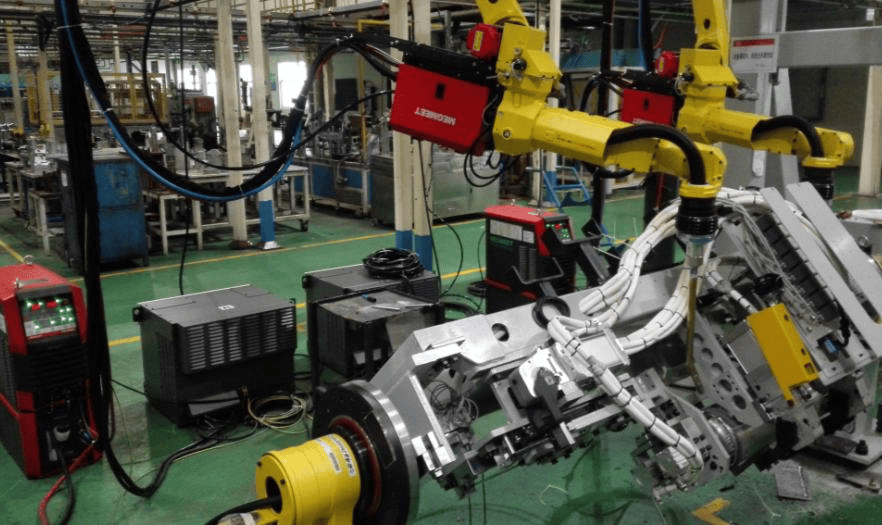

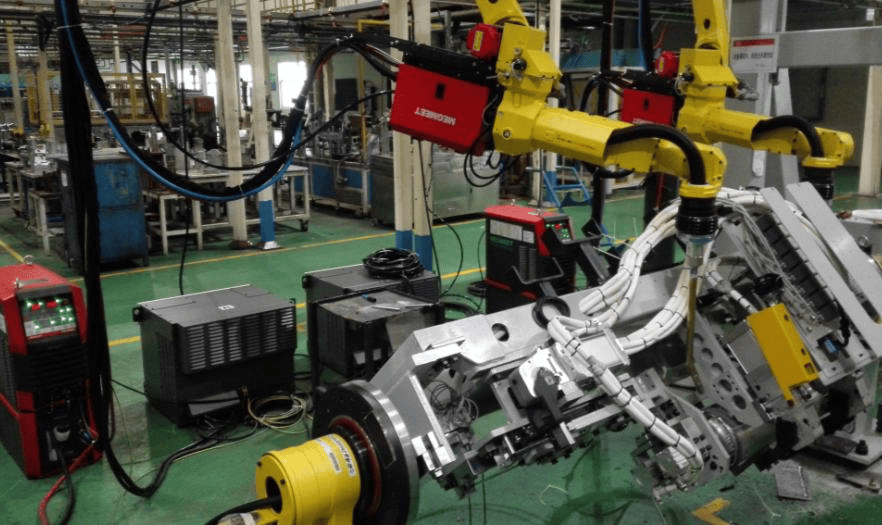

1. Robotic Welding & Automation

High-volume automotive production uses robotic welding arms for consistent, fast, repeatable welds. Automation eliminates many human variabilities (fatigue, inconsistencies) and improves safety by keeping humans out of hazardous zones.

2. Vision, Sensors & Smart Welding

Next-generation systems use cameras, sensors, thermal imaging and AI to guide weld robots, adapt to part variation, detect defects and self-optimise processes. For example, vision-guided robotic welding can identify joint position shifts and correct in real time.

3. Real-Time Quality Control

In resistance spot welding, for example, dynamic resistance curves and other signals provide digital signatures of weld quality—and clustering algorithms can detect deviations and flag potential defects.

Similarly, data from laser welding or FSW can feed into analytics systems for predictive maintenance and process optimisation.

4. Integration with Industry 4.0

Welding systems increasingly form part of the digital manufacturing ecosystem: connected machines, cloud-based analytics, feedback loops for process improvement, traceability for welds (which matters for safety certification).

V. Sustainability in Automotive Welding

Sustainability is no longer optional. Automotive welding must deliver productivity and minimise environmental impact.

1. Energy Efficiency

Modern welding machines reduce idle power consumption, recover heat, optimise process cycles. For example laser and friction-stir processes use less heat input and thus less energy.

2. Reduced Waste & Emissions

Processes with minimal filler material, gas shielding or post-processing (such as FSW) reduce waste. Robotic weld cells prevent re-work and scrap, and high-precision welding reduces distortion and material usage.

3. Lightweighting and Material Efficiency

By enabling joining of lighter materials and mixed-material designs, modern welding contributes to vehicles that consume less fuel (or less battery energy) and thus lower lifetime emissions.

4. Long-Term Durability

Good welding ensures structure longevity, which reduces the need for replacements, repairs or early scrapping of vehicles—further enhancing sustainability of the overall product life cycle.

VI. Best-Practices for Implementation & Repair

Whether you’re on the factory floor or in an automotive repair shop, these practical guidelines apply.

1. Choosing the Right Process

Match welding method to material, joint design, production volume and quality requirements. For sheet-metal body in high volume: RSW or laser + arc hybrid. For non-ferrous alloys: FSW.

Consider repair environment: manual vs robotic, electrode / torch access, ease of setup.

2. Surface Preparation & Weld Setup

Cleanliness matters: remove coatings, paint, rust, oil to avoid weld defects.

Set parameters (current, speed, arc length or tool speed) appropriately and test on scrap if possible.

Use appropriate shielding gas / flux / tool design for the metal involved.

3. Quality Monitoring

Use sensors and data monitoring where possible: electrode force, current/voltage curves (for RSW), arc stability, weld pool geometry.

Visual inspection and, where required, non-destructive testing (NDT) or destructive testing for critical components.

4. Choosing the Right Process

Match welding method to material, joint design, production volume and quality requirements. For sheet-metal body in high volume: RSW or laser + arc hybrid. For non-ferrous alloys: FSW.

Consider repair environment: manual vs robotic, electrode / torch access, ease of setup.

5. Automation & Operator Training

If implementing robotic weld cells: focus on programming, fixture design, safety (barriers, interlocks), maintenance.

For manual operations: ensure operator training, certification, and understanding of material behaviour (especially with mixed materials).

6. Repair Shop Considerations

For mixed-material vehicles (e.g., aluminium + steel body panels) ensure you're using the correct welding method and precautions to avoid galvanic corrosion or weakness.

Maintain up-to-date equipment calibrated for the types of materials you encounter.

VII. Future Outlook

Looking ahead, several trends are shaping the next chapter of welding in the automotive industry.

1. Increased Use of Lightweight & Dissimilar Materials

As vehicle electrification accelerates and regulations tighten, welding techniques capable of reliably joining aluminium, magnesium, copper, steel and composite materials will become more widespread. FSW and hybrid processes will grow.

2. Greater Automation & AI Integration

Robotic welding systems increasingly will be guided by AI, machine-learning models and real-time sensor feedback—reducing human intervention, optimising weld quality and enabling predictive maintenance.

3. Smart Manufacturing Ecosystem

Weld cells will connect to broader manufacturing systems: self-diagnosing weld guns, automatic electrode change, direct traceability of welds in supply chain, and digital twins of welding processes.

4. Sustainability Advancements

Welding methods with even lower energy consumption, minimal consumables, and improved recyclability will be developed. Solid-state welding (FSW) will find more applications, and manufacturing processes will increasingly run on renewable energy.

5. Repair & Retrofit Ecosystem

With vehicles increasingly built from advanced materials, the repair ecosystem will evolve. Mobile weld robots, vision-guided portable welders, and augmented-reality operator support will become more common.

Conclusion

Welding remains a central pillar of automotive manufacturing and repair. In 2025, modern vehicles demand more: joining mixed materials, achieving lighter weight, delivering high throughput, and doing so sustainably. The key welding processes—resistance spot, MIG/GMAW, TIG/GTAW, laser, friction stir and hybrids—are all part of the toolkit. The smart use of automation, sensors, data analytics and process control helps manufacturers and repair shops deliver high quality and consistency.

As materials and vehicle architectures continue to evolve—particularly with electric and autonomous vehicles—the welding industry will adapt, delivering innovations that keep vehicles safe, efficient and competitive. Understanding the right process for the right job, investing in automation and quality control, and always keeping an eye on sustainability will deliver success.

Ready to Upgrade Your Automotive Welding Process?

Explore Megmeet’s cutting-edge automotive welding solutions and discover how we can help you achieve your manufacturing goals. Visit us at https://www.megmeet-welding.com/en/solutions/automotive.

Related articles:

1. Welding the Future of Automotive Manufacturing

2. An in-depth Guide for MIG Welding Automotive Parts

3. Industrial lasers and applications in automotive welding

4. Efficient Welding Technologies and Innovative Welding Solutions For Automotive Industry

5. How to Choose the Best Automotive Welding Equipment?