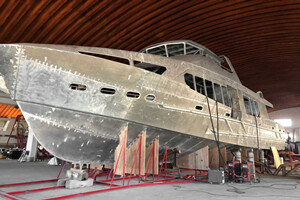

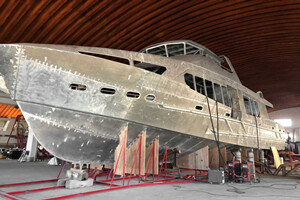

Welding is a cornerstone of modern shipbuilding—structural integrity, fatigue resistance, weld quality and production speed all hinge on how welding is performed. The demands in shipyards are different and tougher than many industrial fabrication shops: large plate sizes, variable fit-up, long weld runs, tough access, and demanding inspection criteria. According to the technical review by TWI, ensuring weld quality in ship construction is critical because flaws cost up to ten times more to repair than they do to avoid.

In this context, choosing the right welding machine is not just about “power output” – it’s about versatility, connectivity, remote control, long-cable stability, process control and robustness in harsh ship-yard conditions. Megmeet Artsen2 CM500C MIG/MAG Welders are engineered precisely with those ship-yard requirements in mind.

This article explores the challenges of ship-yard welding, outlines key machine requirements for shipbuilding, and explains how the CM500C addresses them. At the end, there’s a FAQ section to answer common questions.

1. Importance of Welding Quality in Ship Construction

Welding is not just a fabrication step in shipbuilding — it defines the integrity and service life of the vessel.

Poor welds can lead to deformation, cracking, or even catastrophic failure under stress. That’s why shipyards follow strict quality control standards, including:

ISO 3834 and EN 1090 for welding quality requirements.

AWS D1.1 and D1.2 for structural steel and aluminum welding.

Classification society inspections (e.g., DNV, ABS, LR) before vessel commissioning.

Each welded joint must ensure:

Full fusion and minimal porosity.

Low residual stress to prevent warping.

High toughness and resistance to fatigue and corrosion.

These demands make welding machine performance, process stability, and digital control critical factors in modern shipyard operations.

2. Welding Challenges in the Shipbuilding Industry

Ship-yard fabrication brings specific difficulties:

Large structural plates, heavy sections and long welds. The hull plating, girders, deck beams and bulkheads may span tens of metres. Using welding methods that support long weld runs, high deposition rates, and stable parameters is essential.

Access and cable/run-length issues. Inside hull compartments or in remote parts of the block shop you may have to weld hundreds of feet from the power source. Traditional cabling may cause voltage drop, interference, or cable failure.

Fit-up variability, tight tolerances and high inspection levels. The structural nature of ships means welds must meet demanding codes and classification society rules. Poor fit-up, high distortion or inappropriate machine behaviour leads to defects or rework.

Material mix and process flexibility. Ship structures may combine carbon steel, duplex/stainless steel, aluminium superstructures or transition joints. Machines need to support a variety of processes: CO₂/MAG, flux-cored, gouging and sometimes orbital or mechanised welding.

High productivity and cost-control pressure. With thousands of welds per vessel and tight margins, the machine must help minimise downtime, rework and operator fatigue. Automation or semi-automation is increasingly important.

3. Key features needed in a welding machine for shipyards

From the above, critical machine features for ship-yard use include:

Long-cable and remote control capability – supports remote feeder or torch control so welders can work far from the main unit.

Multi-process flexibility – support for CO₂/MAG, flux-cored wire, MMA/stick, carbon-arc gouging for root or repair work.

High duty-cycle at high amperage – ship structural welds often use high currents or long durations; machine must run reliably at e.g. 500 A or above at full duty.

Robust construction and protection – ship-yard environment is harsh; machine needs vibration, cable-stress, cable-length, electrical-noise resilience.

Parameter storage, remote adjustability & traceability – ability to store welding jobs, lock parameters, monitor performance and support job change-over quickly.

Energy efficiency and cost control – large ship-yard power demands reward efficient machines that reduce electricity losses and downtime.

Connectivity and integration – support for data logging, IoT/Industry 4.0 connectivity, remote diagnostics or robotic integration.

4. How the Artsen2 CM500C meets ship-yard demands

The Artsen2 CM500C series welders are specifically designed by Megmeet Welding Technology to address the unique demands of shipyard welding. These machines pose various advantages.

1) Advanced Technological Features:

Digital Microprocessor Controlled Inverter Technology: The Artsen2 CM500C is equipped with state-of-the-art digital microprocessor-controlled inverter technology, providing precise control over the welding process. This ensures consistent weld quality and minimizes spatter, even in challenging shipyard environments.

Synergic Control of MIG/MAG CO2 Welding Processes: With synergic control, the Artsen2 CM500C simplifies the setup and adjustment of MIG/MAG CO2 welding processes. Welders can achieve optimal welding parameters with minimal effort, increasing efficiency and reducing setup time.

Stable Welding with Extended Stick-Out Lengths: The Artsen2 CM500C allows for stable welding with stick-out lengths of up to 30mm, providing flexibility in welding positions and accessibility in confined spaces. This capability ensures high-quality welds, even in challenging shipyard conditions.

Vertical-Up Welding at 150A: Achieving stabilized vertical-up welding at 150A with flux-cored wire and a 50m interconnection cable set, the Artsen2 CM500C offers versatility and reliability for vertical welding applications commonly encountered in shipyard operations.

2) Enhanced Safety and Compliance Features:

Standard Locking Function: The Artsen2 CM500C comes with a standard locking function for both front panel locking and parameters range locking, enhancing security and preventing unauthorized changes to welding settings.

Job-Saving Features: With standard job-saving features that allow for the storage of up to 10 jobs, the Artsen2 CM500C facilitates quick transitions between different welding tasks, improving workflow efficiency and ensuring consistency in weld quality.

SMARC Welding Cloud System Support: The Artsen2 CM500C supports the SMARC welding cloud system, enabling networking with IoT solutions for real-time monitoring and management of welding operations. This connectivity enhances productivity, traceability, and quality control in shipyard welding processes.

3) Robust Construction and Reliability:

High Duty Cycle: The Artsen2 CM500C boasts a duty cycle of 500A 100% @ 40°C, ensuring continuous performance even in demanding shipyard environments where heavy-duty welding is required.

Multi-Operator System Compatibility: Convenient for building multi-operator systems, the Artsen2 CM500C optimizes resource utilization and productivity in shipyard welding operations.

Proven Record in Heavy Industries: With a proven record in heavy industries since 2014, the Artsen2 CM500C has demonstrated its reliability and durability in the most demanding welding applications.

High Tolerance Against Input Voltage Fluctuation: The Artsen2 CM500C exhibits high tolerance against input voltage fluctuation (25%+/-), ensuring consistent performance and reliability under varying power conditions.

Protection from Environmental Factors: Designed to withstand vibration, collision, moisture, and salty air, the Artsen2 CM500C offers superior protection for its PCB and wire-feeder, minimizing the risk of damage and ensuring long-term reliability in shipyard environments.

Self-Protecting Design and Error Code Display: The Artsen2 CM500C features a self-protecting design and error code display for easy maintenance and troubleshooting, reducing downtime and enhancing operational efficiency in shipyard welding operations.

5. Practical benefits in ship-yard workflows

Fewer machines needed: Instead of separate systems for welding, gouging and repair, the multi-process support reduces footprint and simplifies logistics.

Reduced downtime: With long-cable remote capability, welders can move quickly via scaffolds without needing to reconnect power units or worry about cable drag.

Consistent quality: Job storage and parameter lock-down enable repeatable weld settings, important in ship fabrication where non-conformance is costly.

Improved operator ergonomics: Lighter feeders, fewer cables and longer reach ease welder fatigue and fitting in tight hull spaces.

Better energy/cost control: Given the scale of ship yards (many high-current welds), efficiency gains can translate into significant cost savings over time.

6. Considerations when deploying in ship-yards

While the CM500C offers many strengths, ship-yard procurement should keep an eye on:

Wire-feed and torch system compatibility – Ensure push-pull or long-reach feeders match your scaffolding/fixture layout.

Training & job programming – The rich features (job channels, settings) require disciplined use; welders and supervisors must be trained to avoid parameter mismatch.

Cable routing & ground return paths – Long runs introduce voltage drop and potential noise; ship-yard power conditions must still meet cable and machine spec.

Consumables & service support – Given the heavy usage environment, robust consumable supply and local support strategy are crucial.

Fit-up and distortion management – Machine capability won’t compensate for poor joint fit, misalignment or inadequate fixture. As TWI notes, even advanced systems are limited by fit-up tolerances.

7. FAQs

Q1. Is this machine only for CO₂/MAG welding?

No — it supports CO₂/MAG, MMA (stick) and carbon-arc gouging in a single machine, making it versatile for ship structural welding, repair and re-work.

Q2. Why is remote cable length (100 m) important in ship-yards?

Ship-yards have large blocks, scaffolded compartments and long run-outs. Remote capability allows welders to work far from the main unit without sacrificing arc stability or having heavy control cables.

Q3. What duty-cycle should I look for in ship structural welding?

Heavy structural steel welding often uses high currents (e.g., 400-600 A) and may run extended time. A machine rated for 100% duty at your typical current is highly beneficial to avoid stoppages or overheating.

Q4. How does job channel storage help?

With multiple weld types (e.g., hull plating, stiffeners, decks) and various wire sizes/processes, job storage allows you to recall specific settings quickly, reducing set-up time and mistakes.

Q5. Does this machine support automation or robotic integration?

Yes — documentation shows compatibility with wire-feeder remote panels, parameter networks, job channels and broader connectivity. This enables integration into automated welding lines used in modern ship-yards.

Conclusion:

In the demanding shipbuilding environment—where large plates, diverse materials, long weld runs, tight spaces and high inspection standards converge—choosing a welding machine designed specifically for the challenge is critical. The Artsen2 CM500C delivers key features like long-cable remote performance, multi-process flexibility, high duty-cycle output and job memory that align closely with ship-yard needs.

For procurement managers, welding engineers and ship-yard fabrication leads, this machine represents not just a purchase but a strategic investment in productivity, quality and operational resilience. When used alongside good preparation, fit-up and welding procedure control, it helps ship-yards stay competitive, efficient and compliant in a complex global market. Visit Megmeet Welding to learn more about how the Artsen2 CM500C can transform your welding processes and elevate your capabilities in shipyard welding.

Related articles:

1. Types of Welding Defects in Shipbuilding and Their Remedies

2. Application of Welding Technology in the Shipbuilding Industry!

3. Ship Structural Welding International & Industry Standards

4. 15 Tips for Welding Aluminum in Shipbuilding Industry

5. Shipbuilding Welding - Using Artsen CM500 C Welding Machine