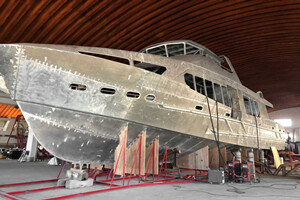

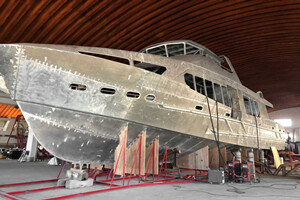

In modern shipbuilding, aluminium structures play an increasingly important role: lighter weight, better corrosion resistance and improved fuel efficiency are major advantages. However, welding aluminium in a shipyard environment presents distinct challenges. Quality, repeatability and speed are critical—and failure to address key factors can lead to high rework, weak joints or costly downtime. This article explores how to boost aluminium welding performance in marine fabrication, with clear, practical steps your team can apply.

Why aluminium welding demands special attention

Aluminium differs from steel in several ways that influence welding: it has a higher thermal conductivity, lower melting point, a tenacious oxide layer and higher sensitivity to contamination (moisture, hydrogen, oxide).

In shipbuilding applications, additional considerations include large plate thicknesses, variable joint fit-up, fatigue and corrosion resistance demands, and the requirement for high productivity. For example, recent reviews note that weld-induced deformation and residual stresses are key in marine aluminium plate welding.

Therefore improving performance means addressing both metallurgical/process fundamentals and shipyard-scale operational practices.

Tip 1. Start with correct base material selection and understand its implications

Selecting the right aluminium alloy for shipbuilding and knowing how it responds to welding is the first foundation. For example, newer marine‐grade alloys such as 5383 or 5059 have been developed to replace older standards (e.g., 5083) in the shipbuilding sector, offering higher yield strength and better fatigue/corrosion properties.

Key actions:

Review which alloy the plate is (5xxx, 6xxx series, etc) and confirm recommended filler and procedure.

Confirm documentation (supplier certificates) for plate temper, thickness and condition—these affect weld behaviour.

For thick hull plates or high-speed craft, consider the alloy’s weldability and the associated filler metal selection.

Outcome: Fewer surprises during welding (poor fusion, cracking or distortion) and a clearer procedure baseline.

Tip 2. Focus intensely on joint preparation, cleaning and fit-up:

Aluminium’s oxide film melts at a far higher temperature than the aluminium beneath it. This means that failing to remove oxide or moisture leads to defects such as porosity or lack of fusion.

In a marine‐scale environment where plates are large and fit-up may vary, consistency in cleaning and fit-up is especially important.

Practical steps:

Ensure plates are stored dry, at stable temperatures; introduce into the welding environment 24 hours in advance if possible to stabilise.

Remove oil, grease, moisture and oxide with appropriate solvent cleaning, followed by a stainless steel brush dedicated for aluminium.

Design joint fixtures and tack-up strategies that maintain consistent gap, alignment and avoid excessive distortion.

Inspect fit-up visually and with gauges: uneven gaps, misalignment or surface oxides can degrade weld quality and productivity.

Outcome: Improved first‐pass quality, less rework, better repeatability and higher throughput.

Tip 3. Match process selection and parameter settings to material thickness and joint type

Aluminium welding in shipbuilding often involves a range of thicknesses (from panels to large hull plates), and each scenario demands an optimized process and parameter set. According to expert guidance, for aluminium:

Short-circuit transfer is generally not recommended due to rapid solidification and risk of lack of fusion or porosity.

Pulsed MIG (or other spray/controlled transfer modes) provide benefits on aluminium: better bead control, less distortion, higher deposition rate.

TIG welding remains useful for thinner materials or when appearance/precision are critical, but slower in deposition.

Recommendations for shipbuilding:

For thick structural plates, ensure the welding machine and wire feed system are capable of the required current and are stable for aluminium’s demanding behaviour.

Calibrate travel speed and heat input: too slow = burn-through or distortion; too fast = lack of penetration or fusion.

Select filler metal compatible with the base alloy, based on table charts or verified procedure qualification.

Outcome: Reduced defects, fewer passes required, better joint integrity and improved weld productivity.

Tip 4. Control heat input, distortion and residual stresses

In the marine aluminium weld context, control of distortion and residual stresses is critical, because hull integrity, fatigue life and dimensional accuracy matter. Recent research highlights that weld-induced deformation and residual stresses have a significant impact on ultimate structural strength of aluminium ship components.

Practical measures:

Use the lowest heat input consistent with achieving full fusion and required mechanical properties.

Minimise wide weaving or unnecessary multi-pass arcs when simpler stringer beads will suffice.

Introduce fixture supports and clamps to restrain distortion during welding—hob-plates, jigging and fixture alignment are key.

After welding, implement controlled cooling or mechanical straightening procedures if needed.

Outcome: Better dimensional control, fewer corrective operations (hammering, grinding), and long-term durability of welded assemblies.

Tip 5. Pay attention to consumables, wire feed‐equipment and welding station logistics

Even in shipbuilding scale operations, poor consumable performance or inconsistent wire feed can dramatically slow productivity or degrade weld quality, especially with aluminium. In industrial aluminium welding, typical issues include bird-nesting (wire tangling), burn-back, inconsistent feed rate, and poor arc stability.

Key focus areas:

Ensure wire feed system is set up for aluminium wire: liner condition, drive rolls properly matched (often U-groove for soft aluminium), minimal slack/twist in gun.

Inspect contact tips, nozzles, liners and torch consumables regularly; build in preventive maintenance intervals.

Verify shielding-gas supply and flow (see next section) as part of consumable planning.

Evaluate work-station layout to minimise poor feed runs (long feeders, awkward routing) and ensure quick consumable changes.

Outcome: Improved arc stability, less downtime for wire feed issues, higher weld consistency and faster production cycles.

Tip 6. Manage shielding gas, flow and environmental conditions:

For aluminium welding, shielding gas strategy and ambient conditions are more critical than many realise—especially in a shipyard where wind drafts, open‐air conditions or variable coverage can interfere.

According to welding practice guides, aluminium welding is especially susceptible to porosity due to hydrogen absorption and oxide contamination.

Best practices:

Use high-purity inert gas (argon) and ensure flow rates are appropriate for thickness and application. For thicker sections or challenging coverage, consider argon/helium blends if justified.

Shield trailing areas, joint gaps and backside of welds appropriately to avoid wind-driven turbulence or contamination ingress.

Maintain gas supply infrastructure: leak-free pipelines, correct regulator settings, monitoring of flow/pressure, and avoid sharing gas supply across many stations without oversight.

Monitor ambient temperature/humidity: aluminium is sensitive to moisture and condensation; ensure parts and consumables are dry.

Outcome: Lower porosity rate, higher first-pass yield, better mechanical and aesthetic weld quality, and lower scrap/rework.

Tip 7. Monitor performance, collect data and apply continuous improvement

In the shipbuilding environment, welding operations of aluminium structures are major contributors to cost and schedule. To improve performance you need feedback loops: measuring, analysing and acting. Recent studies emphasise data capture, residual stress/deflection monitoring and simulation as routes to optimisation.

Implementation suggestions:

Track key metrics: number of welds/pass per shift, rework rate, joint fit-up defects, consumable costs, distortion correction hours.

Use visual dashboards or simple reporting to highlight trends: e.g., if certain weld stations show higher rework, look for root causes (fit-up, operator, consumables).

Hold regular review meetings with welding engineering, fabrication supervisors, consumable/maintenance staff and operators to discuss metrics and corrective action.

Update procedures when improvement opportunities are identified (fixture revision, consumable change, technique adjustment).

Outcome: Continuous upward performance trend, fewer surprises, cost and schedule control, and stronger adoption of best practices.

Tip 8. Train welders and fabricators specifically for aluminium shipbuilding conditions

Even in a semi‐automated or large fabrication environment, the human element remains important. Aluminium welding demands awareness of its peculiarities. Educational guides emphasise cleaning, property differences (oxidation, conduction, heat input) and technique adaptation for aluminium versus steel.

Training focus areas:

Ensure all welders/fabricators understand aluminium’s metallurgical behaviour (oxide layer, heat conduction, porosity risk, distortion) and how this differs from steel.

Run module sessions specifically on joint prep, consumables handling, wire feed system setup for aluminium, gas/wind issues, distortion control.

Maintain practical practice sessions on actual shipyard alloys, thicknesses and joint types (not only thin gauge demo work).

Use cross-discipline training: welding engineers, supervisors, fixture designers, maintenance. Everyone should understand their role in aluminium welding performance.

Outcome: Fewer operator‐caused defects, improved responsiveness to issues, greater ownership of weld-quality performance and efficiency.

Tip 9. Design fixtures, tooling and workflows for repeatability and speed

In ship hull fabrication, many welds are repetitive, but productivity suffers if fixturing, positioning, part handling and workflow are inefficient. Weld speed and consistency are directly tied to how quickly parts are loaded/unloaded and how stable the joint presentation is.

Best practice steps:

Standardise fixture design for similar plate types to reduce set-up time and misalignment.

Use pre-loaded jigs where feasible so welding can commence quickly when the part enters station.

Ensure part presentation (orientation, cleanliness, clamp layout) minimises variation in gap, bevel, angle, edge condition. Variation in joint prep is a frequent cause of rework.

Review part-flow logistics: ensure welders spend minimal time waiting on parts, consumables or quality checks.

Outcome: Higher throughput, shorter cycle time per part, lower non-productive time and improved cost-efficiency.

Tip 10. Maintain quality control, inspection and corrosion/structural integrity considerations

Especially for aluminium used in marine structures, quality goes beyond “looks good” – fatigue life, corrosion resistance, structural integrity under dynamic loading all matter. The ship‐building context demands robust quality control.

Key practices:

Use welding procedures qualified for the specific aluminium alloy and thickness combination; include inspection criteria (e.g., penetration depth, porosity limits, distortion).

Implement non-destructive inspection (NDT) where required: e.g., dye‐penetrant, ultrasonic, radiography as applicable for marine spec.

Post‐weld cleaning and protection: aluminium weld zones may require treatment (removing soot, flux residues if any, ensuring proper coating or surface treatment for marine service).

Monitor for corrosion risk: although aluminium is more corrosion‐resistant than many steels, poor welds, contamination or‐fit issues can localise corrosion.

Outcome: Robust structural performance, reduced warranty or life‐cycle risk, higher customer confidence and fewer in-service failures.

Frequently Asked Questions (FAQs)

Q1: What are the most common defects when welding aluminium plates in a shipyard?

Typical defects include lack of fusion or penetration, porosity (due to hydrogen/moisture or poor gas shielding), burn-through or distortion (from excessive heat input), wire feed problems (bird-nesting) and dimensional distortion/warp. Good practice guides from industrial sources confirm these as core aluminium welding issues.

Q2: Do I need specialized welding machines for marine aluminium welding?

While basic welding systems may work, for large plates and high throughput you’ll benefit from machines designed for aluminium characteristics: good wire feed systems, pulsed transfer capability (for MIG), inverter-based machines that allow better heat input control. The key is match to the job requirements rather than overspending.

Q3: Can aluminium welding performance gains really reduce cost in a shipyard?

Yes. Improved performance means fewer re-passes, less rework, lower consumable/use cost, faster cycles, fewer distortions to straighten, and improved structural quality. Over a large ship hull build these savings add up. Research in marine aluminium welding also shows better monitoring and process stability drive lifecycle cost benefits.

Q4: Is fitting tolerance more critical in aluminium welding than in steel?

Yes, it is. Because aluminium conducts heat rapidly and solidifies more quickly, joint conditions (gap, misalignment, bevel) and how consistently parts are presented matter more. Variation leads to unpredictable weld pool behaviour, increased defects and slower welding speeds. Investing in good fixturing and tolerance control pays off.

Q5: When should I invest in automated or advanced welding technology for aluminium?

When production volume, part repetition, size, joint complexity or quality demand make manual-intensive methods inefficient. For example, if you have many identical large-plate welds, automation, fixture standardisation, offline programming and data monitoring all deliver returns. But even for smaller series ship fab, the fundamentals above deliver major gains without major capital outlay.

Conclusion

Improving aluminium welding performance in shipbuilding is not just about selecting a weld machine—it’s about aligning material, process, tooling, consumables, people and control systems. From choosing the right alloy and preparing the joint, to managing heat input, tracking data and enforcing quality, each element matters.

By focusing on the ten areas above—material selection, joint prep, process tuning, heat/distortion control, consumables/feed, gas/environments, metrics & feedback, training, fixturing/workflow and quality control—you transform welding from a cost centre into a strategic asset.

Implementing these improvements will take coordination across fabrication, engineering, maintenance and quality teams—but the payoff is measurable: fewer defects, higher yield, faster build times and better in-service performance.

If you’d like to adapt these practices to your shipyard environment or explore how your welding team could benchmark performance improvements, feel free to connect with us for a deeper review.

Related articles:

1. Welding Aluminum vs. Welding Steel: Key Differences

2. MIG and TIG Guidelines for Aluminum Welding

3. Advantages of Utilizing Pulsed MIG Welding for Aluminum

4. How to Successfully MIG Weld Aluminum [Guide]?

5. How to TIG Weld Aluminum: A Beginner's Guide