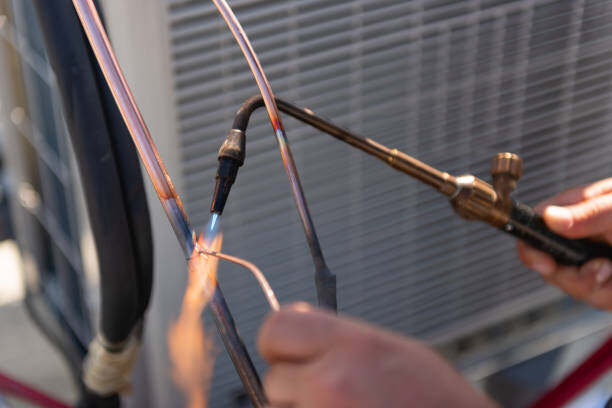

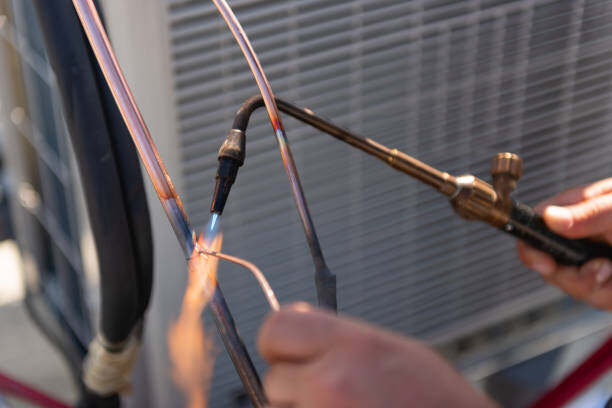

Welding aluminum is often described by professionals as "pushing wet spaghetti through a straw." If you are transitioning from welding mild steel to aluminum, you will quickly find that the hardware and techniques that worked perfectly for years suddenly fall short. Aluminum is soft, it has high friction, and it expands significantly when heated. These physical traits make aluminum MIG wire feeding problems—specifically birdnesting and burnbacks—a daily reality for many shops.

In high-stakes industrial environments, downtime caused by a tangled spool or a fused contact tip isn't just an annoyance; it is a drain on productivity. This guide breaks down why these feeding issues happen and provides practical, hands-on solutions to ensure smooth, stable wire delivery for clean, high-quality aluminum welds.

I. Why Aluminum Wire is Harder to Feed Than Steel?

To solve feeding problems, you first have to understand the metallurgy of the wire itself. Mild steel wire is rigid and has high column strength, meaning you can push it several feet through a gun cable with relative ease. Aluminum wire, particularly the common ER4043 and ER5356 alloys, lacks this stiffness.

Low Column Strength: Because aluminum is so soft, any resistance in the feeding path—whether it is a dirty liner or a tight bend in the cable—causes the wire to buckle. Instead of pushing through the obstruction, the wire folds over itself at the drive rolls.

High Coefficient of Friction: Aluminum wire "grabs" the surface of traditional steel liners. This friction creates drag, which requires the motor to work harder, leading to slippage or wire deformation.

Thermal Expansion: Aluminum expands much more than steel as it heats up. As the wire passes through the contact tip near the arc, it grows in diameter. If the tip isn't specifically sized for aluminum, the wire will seize inside, causing a "burnback."

II. Common Symptoms of Aluminum MIG Wire Feeding Issues

Before diving into the fixes, you need to identify what exactly is going wrong. Most feeding issues manifest in three ways:

Birdnesting: This is the most infamous aluminum welding problem. It occurs when the wire tangles and bunches up between the drive rolls and the inlet guide of the gun liner. It usually happens because the wire hit an obstruction further down the line, but the drive rolls kept pushing.

Burnbacks: The wire effectively welds itself to the inside of the contact tip. This stops the feed instantly and often requires the operator to replace both the tip and the wire.

Erratic Arc: If you notice your arc "fluttering" or jumping, it is often a sign of inconsistent wire speed. This can be caused by the drive rolls slipping on the wire or micro-snags inside the liner.

III. Solution 1: Setting Up the Right Drive Rolls and Tension

One of the most common mistakes is using standard "V-groove" drive rolls designed for steel. V-grooves are shaped to pinch the wire to get a grip. On soft aluminum, this pinch deforms the wire into an oval shape, making it much more likely to jam in the contact tip. It also "shaves" the wire, creating tiny aluminum flakes that clog your liner.

1) Use U-Groove Rolls

Always use U-groove drive rolls. These have a semi-circular bottom that cradles the wire without crushing it. This keeps the wire perfectly round and minimizes shaving.

2) The "Wood Block" Tension Test

Setting the drive roll tension is a balancing act. If it is too loose, the rolls slip. If it is too tight, you’ll cause birdnesting if there is even a minor snag.

The Test: Release the drive roll tension. Feed the wire out of the gun and point it at a piece of wood or a flat surface. Gradually tighten the tension until the wire feeds against the wood and begins to curl into a "c" shape without slipping at the rolls.

Pro Tip: Use the lowest possible tension that still provides consistent feeding. For aluminum, less is almost always more.

IV. Solution 2: The Importance of Non-Metallic Liners

If you are using a standard helically wound steel liner for aluminum, you are asking for trouble. Steel liners act like a file against the soft aluminum wire, scraping off shavings that eventually accumulate and block the path.

1. Switch to Teflon or Nylon

For aluminum, Teflon (PTFE) or Nylon liners are mandatory. These materials have a very low coefficient of friction, allowing the wire to slide through with minimal resistance.

2. Maintenance Tip: The Blow-Out

Even with a Teflon liner, aluminum dust can accumulate over time. Every time you change a spool of wire, use clean, compressed air to blow out the liner from the torch end back toward the feeder. This removes any debris before it can cause a jam.

V. Solution 3: Properly Sizing Contact Tips for Aluminum

Standard contact tips are sized for steel. Because aluminum expands as it absorbs heat from the arc, it requires more "room" inside the tip.

Oversized Bore: Aluminum-specific contact tips have a slightly larger inside diameter (ID) than steel tips of the same size. For example, a tip labeled for.035" aluminum is actually bored larger than a.035" steel tip.

Burnback Prevention: If you use a steel tip, the aluminum wire will expand, seize, and fuse to the tip, causing a burnback. Always check that your tips are specifically stamped for "AL" or "Aluminum."

VI. Solution 4: Choosing the Right Feeding System

Sometimes, no matter how much you fine-tune a standard MIG gun, the distance is simply too great for the soft wire to travel. In these cases, industrial shops switch to specialized feeding systems.

| System Type | Best For | Pros | Cons |

| Push-Only | Small jobs, large wire (.045"+) | Low cost, simple | Prone to birdnesting with thin wire |

| Spool Gun | Mobile work, thin wire | Shortest feed path (<12 inches) | Heavy torch, limited to small 1-lb spools |

| Push-Pull Gun | High production, long reaches | Feeds up to 30ft; uses two motors | Expensive setup; more complex to maintain |

VII. Practical Troubleshooting Guide

If you encounter feeding problems mid-weld, use this table to quickly diagnose and fix the issue.

| Symptom | Probable Cause | Immediate Solution |

| Birdnesting at drive rolls | Too much roll tension or clogged liner | Loosen tension; check/replace liner |

| Wire fused to contact tip (Burnback) | Tip is too small or WFS is too low | Increase WFS; use aluminum-specific tip |

| Erratic, "stuttering" arc | Drive rolls are slipping | Check for U-groove rolls; clean |

| Wire is wavy exiting the gun | Excessive drive roll pressure | Decrease tension until wire is round |

| Black soot on the weld | Inconsistent gas/wire feed | Straighten gun cable; check gas flow |

VIII. Best Practices for Handling Aluminum Spools

Often, the problem starts before the wire even reaches the drive rolls. Aluminum wire is sensitive to how it is handled and stored.

Handle with Care: Always lift wire spools by the center or the bottom. Never lift them by the flanges. If the flanges flex, it can disrupt the precision-wound layers, causing the wire to snag as it unspools.

Brake Tension: Set the spool brake tension so it is just tight enough to stop the spool from "freewheeling" when you stop welding. If it's too tight, the feeder has to pull harder, which can lead to slippage.

Storage and Moisture: Aluminum is prone to oxidation. Store spools in a dry, heated environment. If a cold spool is brought into a warm shop, moisture will condense on the wire (hydration), which leads to porosity and increased friction.

IX. FAQs: Aluminum MIG Wire Feeding

Q1: Can I weld aluminum with a standard 15ft MIG torch?

A: It is possible with a Teflon liner and U-groove rolls, but it is risky. For aluminum, the shorter the torch, the better. Most experts recommend keeping a push-only torch under 10-12 feet to minimize buckling.

Q2: Why does my wire keep "birdnesting" even with U-groove rolls?

A: Check your inlet guide and the gap between the drive rolls and the liner. If there is a large gap, the soft wire has space to buckle. Also, ensure your cable is as straight as possible while welding.

Q3: Should I use.030" or.035" wire for aluminum?

Q4: Is preheating necessary for better feeding?

Master the Feed with Megmeet Industrial Welding Machines

Reliable wire feeding is the foundation of successful aluminum MIG welding. Even with the correct wire, liner, and torch setup, inconsistent power output or unstable control can quickly lead to feeding interruptions, arc instability, and weld defects. This is especially critical in aluminum applications, where soft wire characteristics leave little margin for error.

Megmeet industrial welding machines are engineered to deliver stable arc performance and precise wire feed control under demanding production conditions. With advanced digital control systems, optimized aluminum welding programs, and compatibility with push-pull and spool gun configurations, Megmeet equipment helps minimize common issues such as birdnesting, burnback, and irregular feeding.

For manufacturers aiming to improve aluminum MIG welding consistency and reduce downtime, Megmeet provides heavy-duty, production-ready solutions that support smooth wire feeding, stable arcs, and repeatable welding quality.

Related articles:

1. How to Successfully MIG Weld Aluminum [Guide]?

2. Advantages of Utilizing Pulsed MIG Welding for Aluminum

3. Pulsed MIG Welding Aluminum and Stainless Steel

4. MIG and TIG Guidelines for Aluminum Welding

5. MIG Welding Aluminum Essential Tips and Techniques