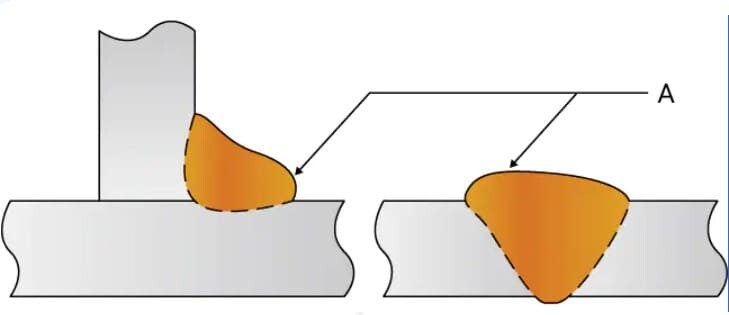

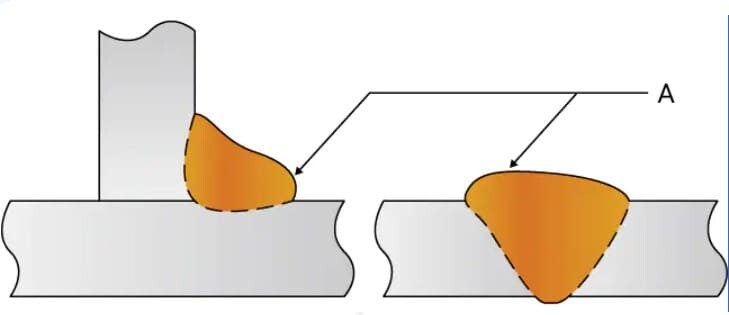

Overlapping welding is a common welding defect that occurs when the filler metal flows beyond the weld toe or root, creating an excess layer of material that does not properly fuse with the base metal. Overlapping welding can affect the appearance, cost, and quality of the weld, and should be avoided whenever possible.

In this article, we will explain what causes overlapping welding, how to prevent it, and how to fix it if it happens. We will also introduce you to some of the best welding products from Megmeet Welding Technology (the following: Megmeet), a leading manufacturer of welding equipment and solutions.

I. What Causes Overlapping Welding?

There are four main factors that can cause overlapping welding: amperage, travel speed, electrode selection and usage, and welding technique. Let’s take a closer look at each one.

1) Amperage

Amperage or current is the amount of electricity that flows through the welding circuit. If the amperage is set too high, it can result in excess filler metal in the weld pool, which can overflow and solidify improperly. To avoid this, you should check a settings chart to determine the optimal amperage for your specific job, and perform test welds to fine-tune your settings. If you notice overlapping welding, you should lower the amperage gradually until you achieve a clean weld.

2) Travel Speed

Travel speed is the rate at which you move the welding torch or electrode along the joint. If the travel speed is too low, it can cause filler metal to accumulate in the weld pool, leading to overlapping welding when the filler metal cannot properly fuse with the parent metal. The remedy is simple: Increase your travel speed if you notice overlapping welding. However, be careful not to go too fast, as this can introduce other problems, such as lack of penetration or undercutting. The key is to find a balanced travel speed that prevents overlapping welding while avoiding other defects.

3) Electrode Selection and Usage

Electrode selection and usage can also affect how much filler metal is deposited in the weld pool. Choosing the wrong electrode size or angle can lead to overlapping welding by affecting how much filler metal is added to the weld pool. To prevent this, you should select the correct electrode size and angle for your job, based on factors such as material thickness, joint type, position, and polarity. You should also avoid using worn-out or contaminated electrodes, as they can introduce impurities or inconsistencies in the weld pool.

4) Welding Technique

The welding technique is perhaps the most important factor in preventing overlapping welding. Welding technique refers to how you manipulate the welding torch or electrode during the welding process. A good welding technique involves maintaining a consistent arc length, a steady travel speed, a proper work angle, and a smooth motion. A poor welding technique can result in overlapping welding by causing irregularities in the weld pool, such as turbulence, spatter, or slag inclusion.

II. How to Prevent Overlapping Welding

Prevention is always better than repair. Implement these best practices to minimize the risk of overlapping welding:

1. Optimize Amperage and Voltage

2. Adjust Travel Speed

Maintain a steady and balanced travel speed to prevent filler metal accumulation.

Avoid excessive speed, as it may lead to a lack of penetration or undercutting.

3. Select the Right Electrode

4. Improve Welding Technique

III. How to Repair Overlapping Welds

If overlapping welding occurs despite preventive measures, repair is necessary. Follow these steps to fix the defect:

1. Assess the Defect

2. Remove Excess Material

Use grinding, chipping, or gouging techniques to remove the overlapping layer.

Ensure the area is clean and free from slag or contaminants.

3. Re-Weld the Joint

IV. Megmeet: Your Trusted Partner for Welding Solutions

If you are looking for high-quality welding products and solutions, you should check out Megmeet Welding Technology, a leading manufacturer of welding equipment and solutions in China. Megmeet offers a wide range of welding products and provides customized welding solutions, such as welding automation, welding system integration, and welding process optimization. With over 20 years of experience, Megmeet provides:

Advanced Welding Machines: Equipped with high-frequency inverter technology for precise control.

Customized Welding Solutions: These are tailored to meet the specific needs of your industry.

Comprehensive Quality Control: Ensuring durability and reliability in every product.

Megmeet is committed to providing its customers with the best welding solutions possible, and helping them achieve their welding goals efficiently and effectively. Whether you need a simple welding machine or a complex welding system, Megmeet can help you find the right solution for your job. To learn more about Megmeet and its products and solutions, please visit their website at https://www.megmeet-welding.com/en.

V. Conclusion

Overlapping welding is a common welding defect that can affect the quality and appearance of your weld. It is caused by various factors, such as amperage, travel speed, electrode selection and usage, and welding technique. To prevent overlapping welding, you should follow the best practices for each of these factors, and inspect your work area and equipment before and during your job. To fix overlapping welding, you may need to remove the excess material and re-weld the joint, depending on the severity and impact of the defect.

If you are looking for high-quality welding products and solutions, you should check out Megmeet, a leading manufacturer of welding equipment and solutions. Megmeet offers a wide range of welding products and solutions for various applications and industries. Megmeet also provides customized welding solutions to meet your specific needs and challenges.

We hope this article has helped you understand what overlapping welding is and how to avoid it. If you have any questions or feedback, please feel free to contact us.

Related articles:

1. How to Avoid Porousness in TIG Welds?

2. How to avoid blow holes defects in submerged arc welding?

3. How can we weld stainless steel without causing it to burn?

4. Common Dangers of Welding and How to Avoid Them

5. How To Weld Cast Iron And Avoid Weld Cracking?