In welding, a sound joint depends on the molten weld metal successfully joining and bonding with the base metal (and — in multi-pass welding — with previous weld passes). When that bond does not form properly, the defect is referred to as lack of fusion (LOF), sometimes also described as “incomplete fusion.”

More precisely, LOF describes a condition where the weld metal fails to fuse completely with at least one of:

the base material (side walls or joint faces)

the root of the joint (in a butt or groove weld)

a previously deposited weld bead (inter-run or inter-pass fusion)

Because the result may be an internal discontinuity — effectively an unbonded plane — LOF compromises structural integrity. Under load, such discontinuities can act like cracks or stress concentrators, undermining strength, reducing fatigue resistance, or causing catastrophic failure in critical applications (pressure vessels, structural weldments, pipelines, etc.)

Therefore, ensuring proper fusion is cornerstone for weld quality — and preventing LOF is a central concern for any welding procedure.

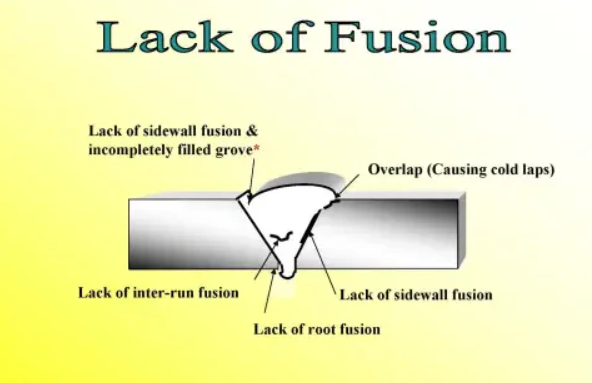

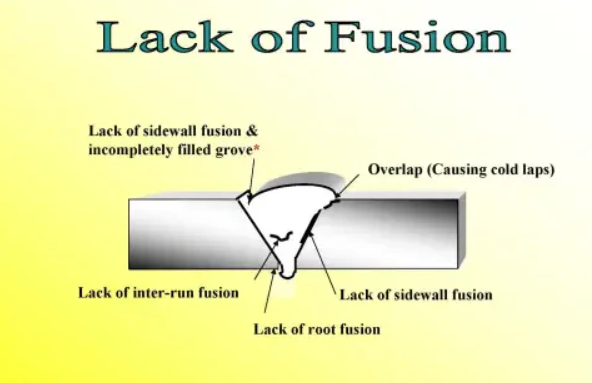

I. Where and What Types of Lack of Fusion Occur?

LOF can occur in different parts of a weld joint depending on geometry, process, and technique. Common types are:

Side-wall fusion defect: the weld metal fails to properly fuse to one or both side walls of the joint.

Inter-run / inter-pass fusion defect: where a subsequent weld bead does not fuse adequately with the previously deposited weld bead.

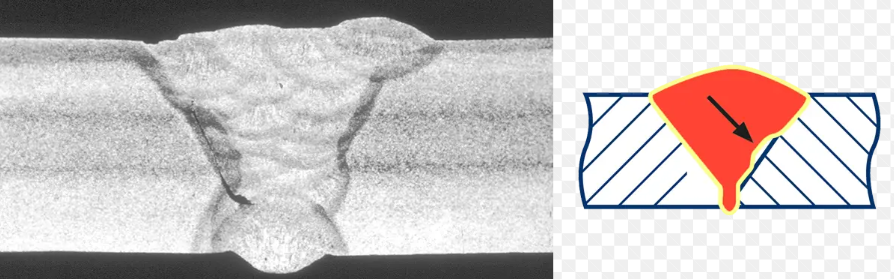

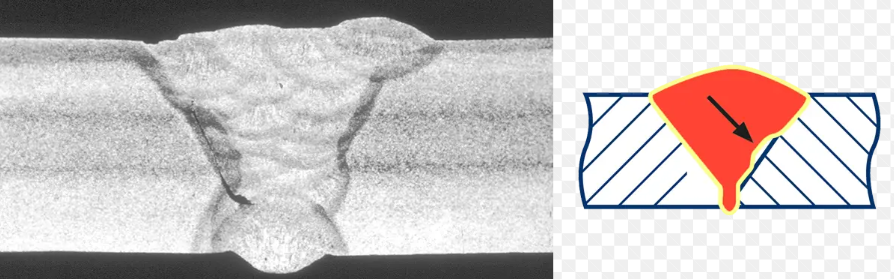

Root fusion defect: especially in butt or groove joints, the weld fails to fuse completely at the root or bottom of the joint.

Micro-lack of fusion: small, often sub-surface defects that may not be visible but can propagate under stress.

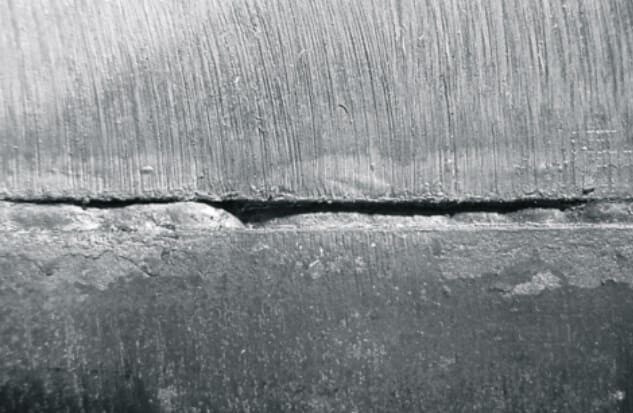

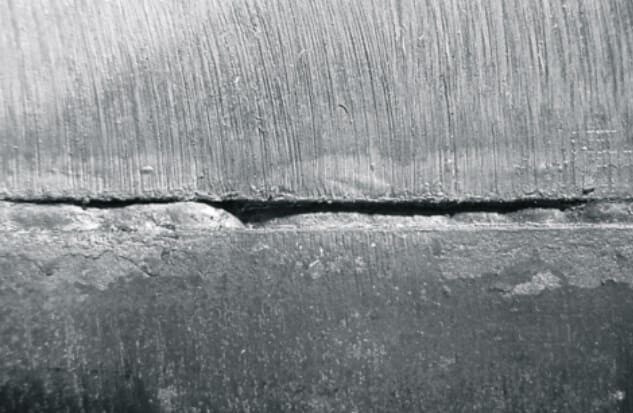

Because these are often internal discontinuities — not always visible on the weld surface — LOF can be insidious and may pass unnoticed unless proper non-destructive testing (NDT) is employed.

II. What Causes Lack of Fusion in Welding?

LOF does not arise randomly — it is usually the result of deficiencies in joint design, preparation, equipment setup, or welder technique. Major contributing factors include:

1) Inadequate Heat Input / Incorrect Welding Parameters

If the welding current (or energy input) is too low, the arc may not generate enough heat to melt the base metal sidewalls or previous weld bead sufficiently for fusion.

A long arc length (or too soft/wide an arc) reduces penetration capability — the arc becomes less focused, leading to shallow weld pools and poor fusion.

Excessive welding speed (travel speed) relative to current may outpace the heat input needed for good fusion, causing the weld pool to “ride over” cold base metal.

2) Poor Joint Design or Inadequate Fit-up

A joint preparation with too narrow a groove, improper bevel, or too small root gap restricts access for the arc and filler to reach all fusion surfaces — sidewalls or root — increasing LOF risk.

Misaligned parts, excessive root face, or incorrect edge geometry inhibit full penetration or lead to uneven melting.

3) Contamination / Surface Condition

Presence of rust, mill scale, oil/grease, paint, oxidation, or other contaminants can block proper wetting and metallurgical bonding, preventing fusion between weld metal and base material.

In multi-pass welding, failure to clean between passes (e.g. slag, spatter, oxidation) can cause inter-run fusion defects.

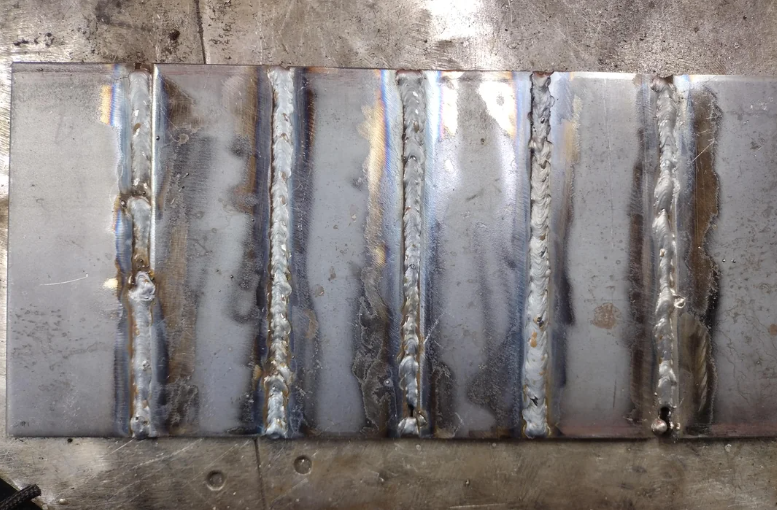

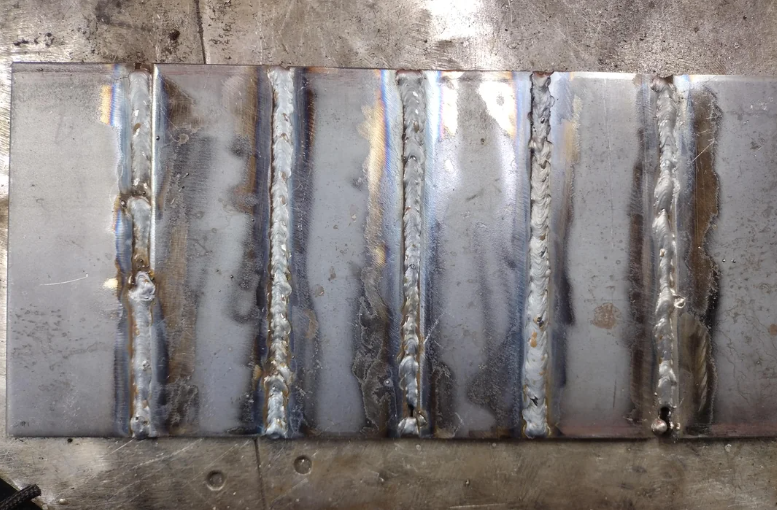

4) Poor Welder Technique or Manipulation

Incorrect torch or electrode angle — for example, too steep, too flat, or misaligned — can steer the arc away from sidewalls, leaving them unfused.

Improper bead placement, poor weave / oscillation, or too little “dwell” time at sidewalls may prevent the weld pool from properly washing into the parent metal.

In multi-pass welding, incorrect layering without proper inter-pass cleaning or correct overlap may create inter-run fusion defects.

5) Additional Factors (Process-Specific)

In certain processes (e.g. electrode-based welding), electrode size and type relative to joint configuration may prevent proper root access or penetration.

In ferromagnetic materials and DC-based welding processes, magnetic arc-blow or arc deflection can distort arc path, causing inconsistent fusion or missing one side wall.

III. Consequences of Lack of Fusion — Why It’s Dangerous?

Failing to fuse properly can lead to many negative outcomes:

Weakened joint strength: The welded joint may not carry designed loads; on load or cyclic stress, LOF zones may act like pre-existing cracks.

Fatigue and crack propagation: LOF discontinuities act as stress concentrators — over time, under repeated loads, these may propagate to full cracks, causing failure.

Leakage or rupture (in pressure-containing weldments, pipelines, pressure vessels): If LOF occurs at root or sidewalls, it can compromise pressure integrity.

Hidden defects (sub-surface instability): Since LOF may be internal, visual inspection alone is often insufficient — giving false sense of weld quality.

Because of these risks, LOF is among the most serious welding defects; codes and standards governing critical structures often forbid long runs of incomplete fusion, or severely limit defect size and occurrence.

IV. How to Detect Lack of Fusion in Welding?

Given many LOF defects are internal or sub-surface, relying solely on visual examination is risky. Effective detection methods include:

Visual inspection: This is the simplest and most common method of detecting lack of fusion. The welder can look for signs of lack of fusion, such as gaps, cracks, or porosity in the weld. However, this method may not be able to detect a lack of fusion that is hidden below the surface or at the root of the weld.

Dye penetrant test: This is a non-destructive test that involves applying a dye to the weld and then using a developer to see if any dye has penetrated into the joint. This indicates that there is a lack of fusion or other defect in the weld.

X-ray test: This is another non-destructive test that uses an X-ray machine to see if there are any voids or porosity in the weld. This can help to detect lack of fusion that is not visible to the naked eye.

V. How to Prevent Lack of Fusion in Welding?

Preventing LOF requires discipline throughout welding — from design to final pass. Below are proven best practices and recommendations:

1) Design & Prepare the Joint Correctly

Use an adequate joint geometry: proper groove angle, root gap, and root face — allowing the arc and filler to access all fusion surfaces. Avoid excessively narrow joint preparations that limit arc access.

Ensure accurate fit-up and alignment; avoid misalignment, excessive root face, or gaps that exceed allowable tolerances. Tacking must maintain the root gap.

For multi-pass welds: plan for inter-pass cleaning (wire-brushing or grinding as necessary) to remove slag, spatter or oxide before depositing the next pass.

2) Control Welding Parameters and Heat Input

Select an appropriate current/amperage level — high enough to achieve proper penetration and side-wall fusion, but not so high as to cause excessive melt, burn-through, or distortion.

Maintain a short, properly focused arc (not a long, soft arc) to ensure penetration rather than a wide, shallow weld pool.

Adjust travel speed: too fast will reduce heat input per unit length, risking LOF; too slow (with high heat) may cause excessive deposition, but also risk defects like undercut or burn-through. Balance carefully.

Choose proper electrode or filler size, type, and polarity (if applicable). Oversized electrodes for the joint may prevent root penetration or side-wall access.

3) Maintain Proper Welding Technique & Torch/Electrode Manipulation

Ensure correct torch or electrode angle and gun manipulation during welding — avoid angles that steer the arc away from sidewalls.

When appropriate and permitted by procedure, use a slight weave or dwell at the sidewalls to allow the weld pool to “wash into” the parent metal — improving fusion.

In multi-pass welding: clean between passes — remove slag, spatter, oxide — to ensure the next pass fuses cleanly to the previous bead.

4) Ensure Surface Cleanliness & Material Preparation

The surfaces to be welded — joint faces, root, sidewalls — must be free from oil, grease, scale, mill-scale, paint or oxidation that could inhibit fusion.

For materials prone to oxide formation (or previously exposed to environment), remove oxide by mechanical cleaning (wire-brush for nonferrous/ferrous accordingly), grinding, or proper chemical cleaning depending on material type.

5) Choose Appropriate Welding Process & Consumables

Use electrodes, filler wires or consumables matched to the joint design, material type, and application. Avoid over-sized electrodes or inconsistent consumables that would hinder proper fusion.

Ensure correct shielding and environmental controls (if relevant), especially in processes sensitive to contamination (though LOF is more about fusion than gas shielding, still cleanliness helps).

6) Post-Weld Inspection and Quality Control

For critical structures: employ non-destructive testing (NDT) such as radiographic testing or ultrasonic testing to detect internal LOF flaws not visible from the surface.

In production or repeated welding: periodically perform destructive testing (macro-etch or sectioning) on sample welds during procedure qualification to verify fusion quality.

If LOF is detected, defective weld sections must be removed (gouged or ground out) and re-welded per qualified welding procedure.

VI. Common Misconceptions & Frequently Asked Questions

Q1: Is lack of fusion just a cosmetic issue?

A: No. Unlike cosmetic defects, LOF represents an actual metallurgical discontinuity — often internal — that undermines structural integrity. In many cases it behaves like a crack or pre-existing flaw, reducing load-bearing capacity and fatigue resistance.

Q2: Can't we just rely on visual inspection to ensure weld quality?

Q3: Does increasing welding heat always fix LOF?

A: Not always — while insufficient heat is a common cause, excessive heat input or incorrect manipulation can lead to other defects (burn-through, undercut, distortion). Prevention requires balanced parameters, correct joint design, clean surfaces, and proper welding technique.

Q4: In multi-pass welds, is inter-run fusion usually a problem?

Conclusion

Lack of Fusion (LOF) remains one of the most serious welding defects — a silent threat that can undermine weld integrity from inside, often without visible surface signs. It is not an aesthetic flaw but a structural risk.

Preventing LOF requires attention at every step: from correct joint design and fit-up; through clean surface preparation; to proper selection of welding parameters (heat input, arc, travel speed), meticulous welding technique, and thorough inspection (including NDT when appropriate).

For fabricators, OEMs, and end-users relying on welded components for structural integrity, safety, or pressure containment: enforcing LOF-prevention practices is essential.

Related article:

1. Welding Defects, Problems And Easy Solutions [2023]

2. Undercut Welding Defect: Causes, Prevention, and Repair

3. Tips for Troubleshooting Common MIG Weld Defects

4. How to Identify the 7 Most Dangerous Welding Defects?

5. How to avoid blow holes defect in submerged arc welding?