I. Product Introduction

MEGMEET CO₂/MAG/MIG/TIG/MMA/ Carbon Arc Gouging all-in-one welding machine ---full digital IGBT inverter multi-function welding machine Ehave-2 CM series.

II. Welding Process

1) CO2 /MAG/MIG Function

Both synergic/separate modes are available, and key parameters are adjusted automatically to meet high-quality welding requirements.

Support 0.8, 1.0, 1.2, 1.4, 1.6mm welding wire, and 0.9, 2.0, 2.4, and 2.8mm wire process can be customized(SP).

Support MAG flux-cored carbon steel and MIG DC stainless steel process.

2) Simple DC TIG Function

Scraping/lift arc ignition function

Through overlapping control of the arc to reduce tungsten damage, the arc ignition success rate reaches 100%.

With abundant parameter settings, suitable for all kinds of welding operations from thin plate to medium-thick plate.

3) MMA FUNCTION

Can quickly switch to “MMA function”, and the maximum diameter for welding rod is 6.0mm.

Capable for long cable operation, and arc starting current and thrust current can be adjusted.

4) Carbon arc gouging function

5) RFID Card-swiping

Efficiently realize the binding of welders and machines.

Be able to match with Megmeet smart welding cloud platform/system(SMARC), supporting more intelligent functions such as parameter issuing, welding hours statistics, and welding parameter trace.

6) USB Interface

Ensure customers enjoy the most cutting-edge welding processes and the function customization of Megmeet conveniently.

Be able to send software by email, and customers can download it to a USB disk and upgrade their welding machines.

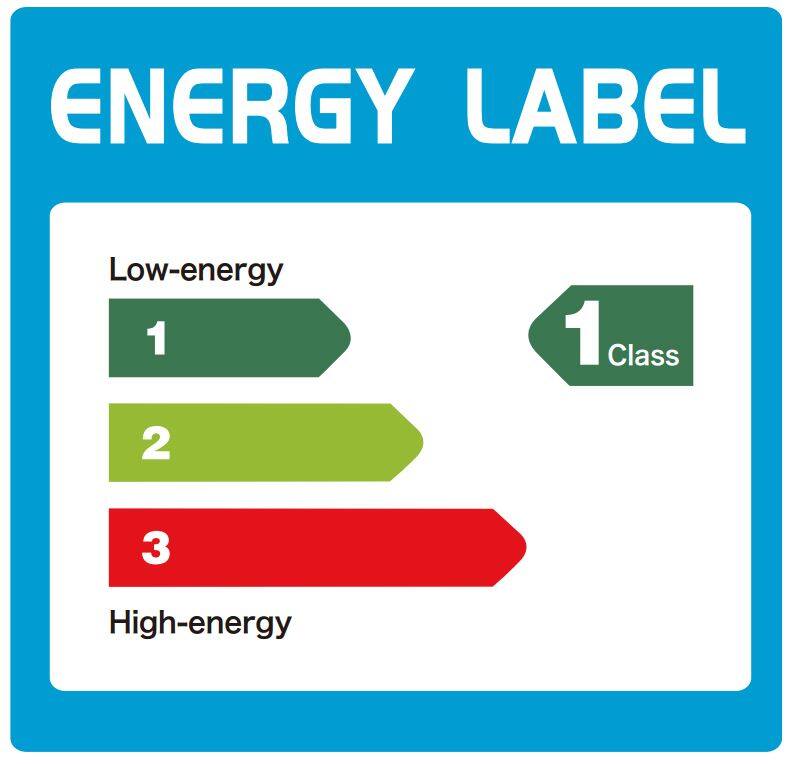

7) 1st Class Energy Efficiency

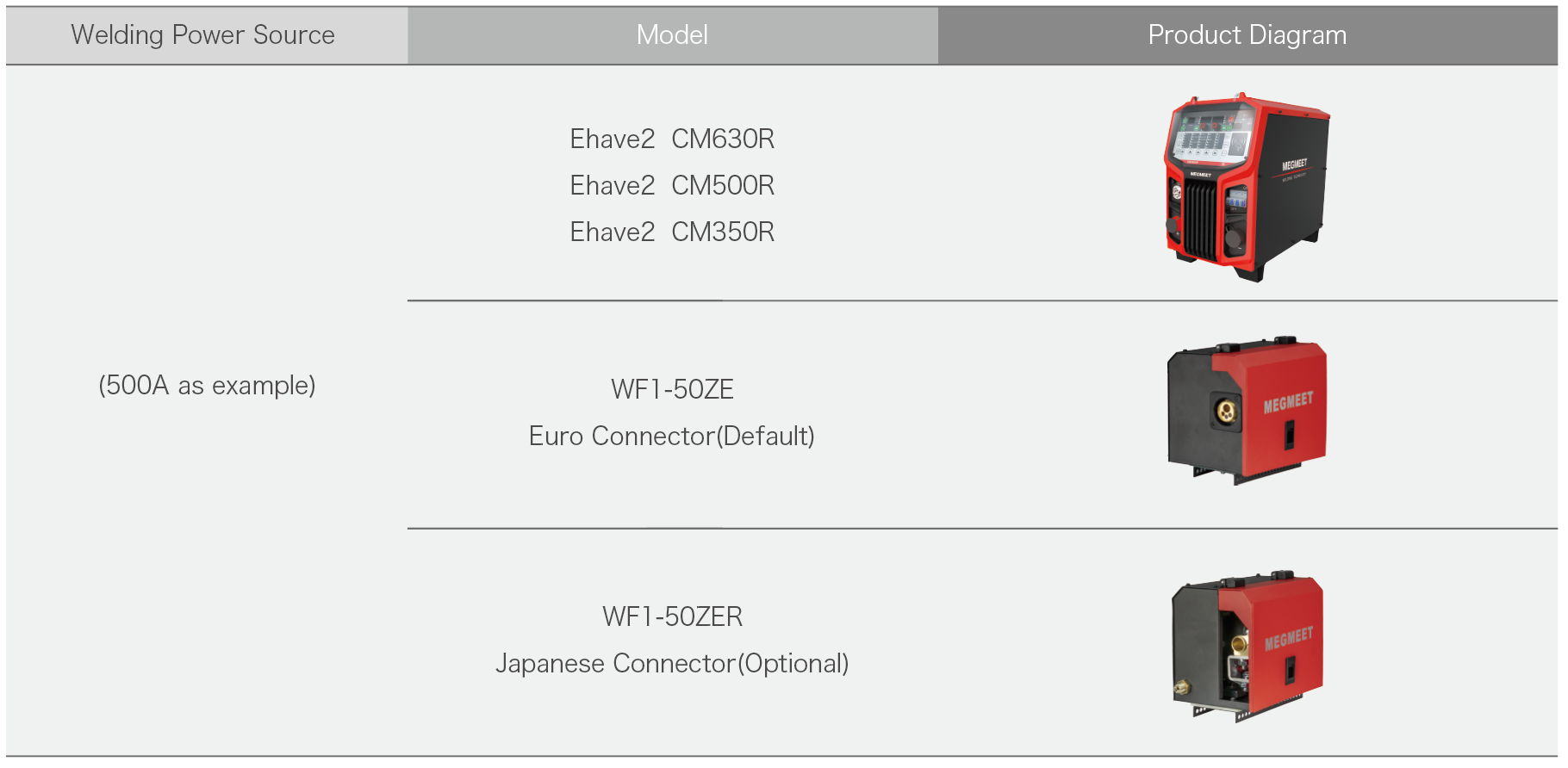

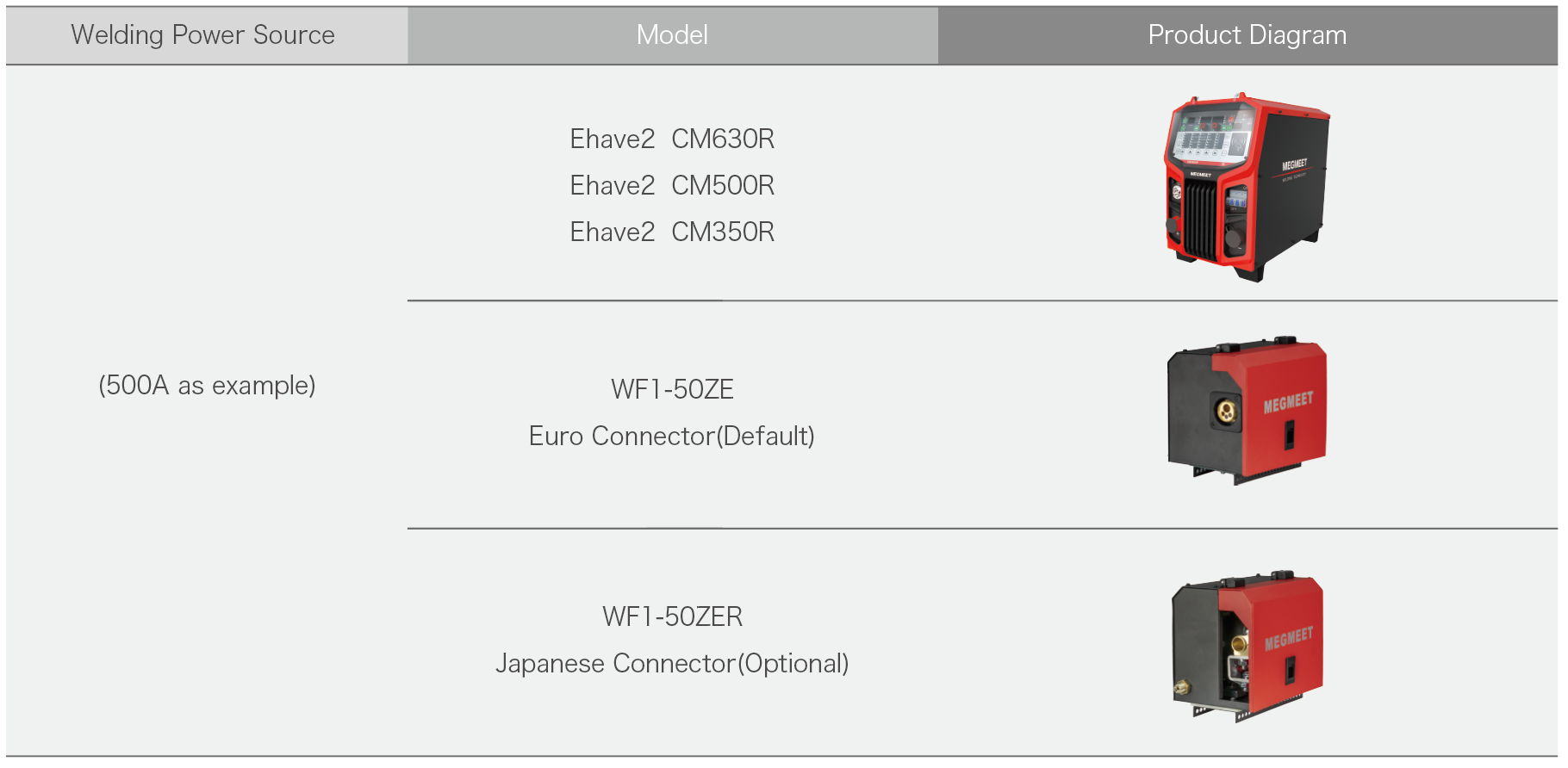

III. Multiple Wire Feeders Can Be Freely Selected

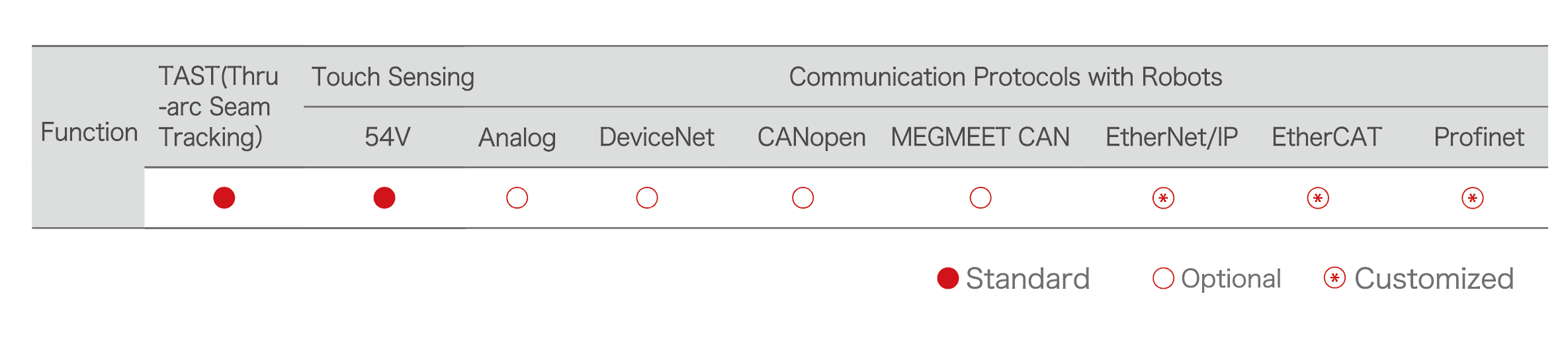

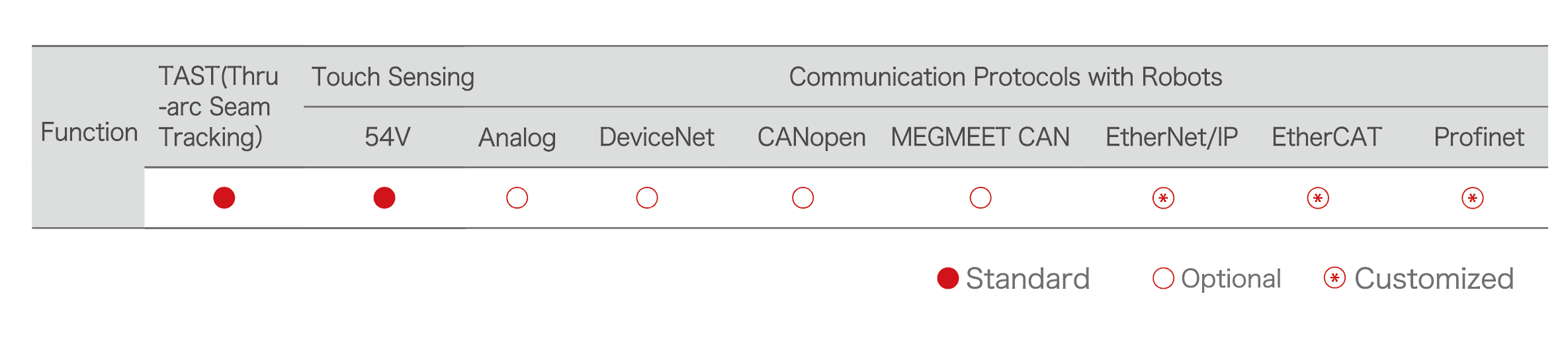

IV. Robot Communication

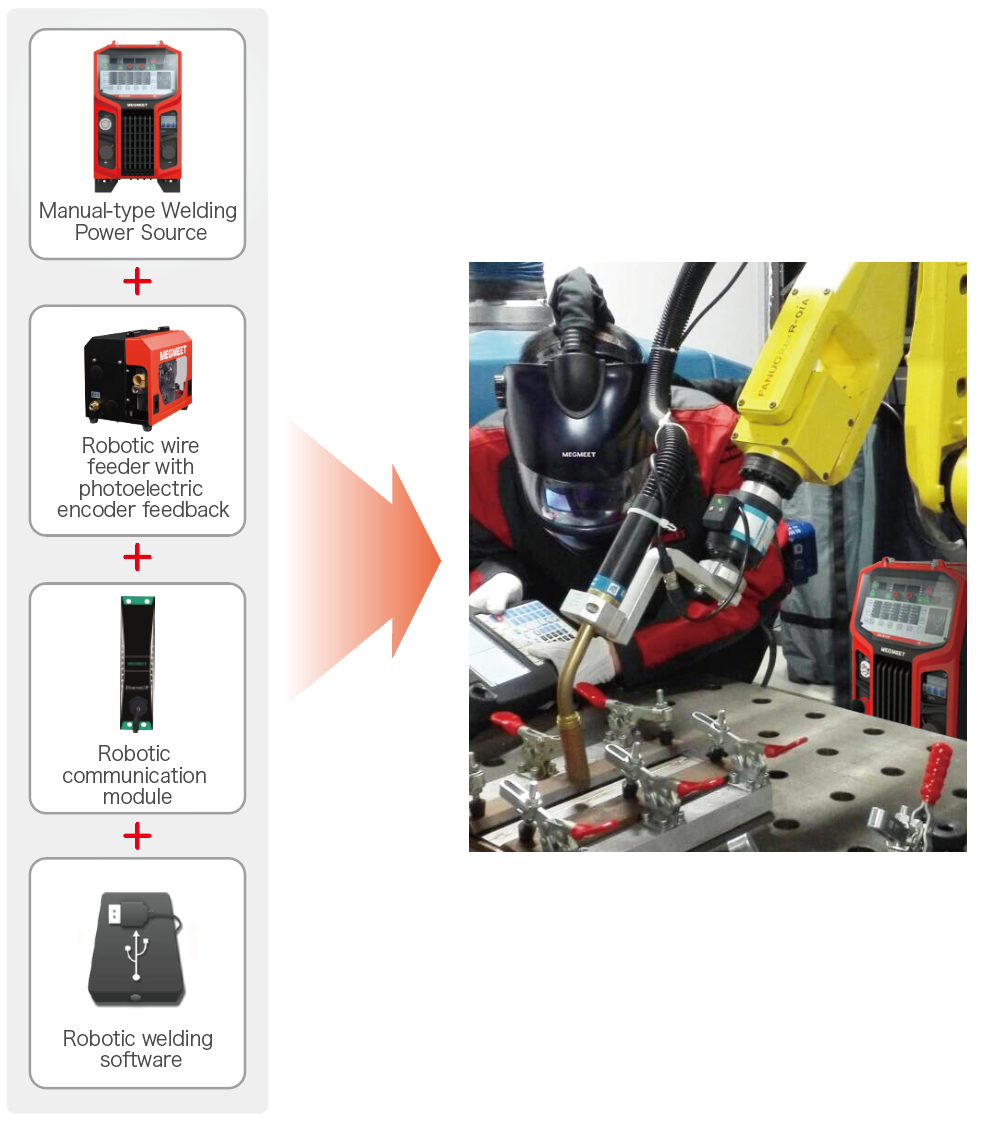

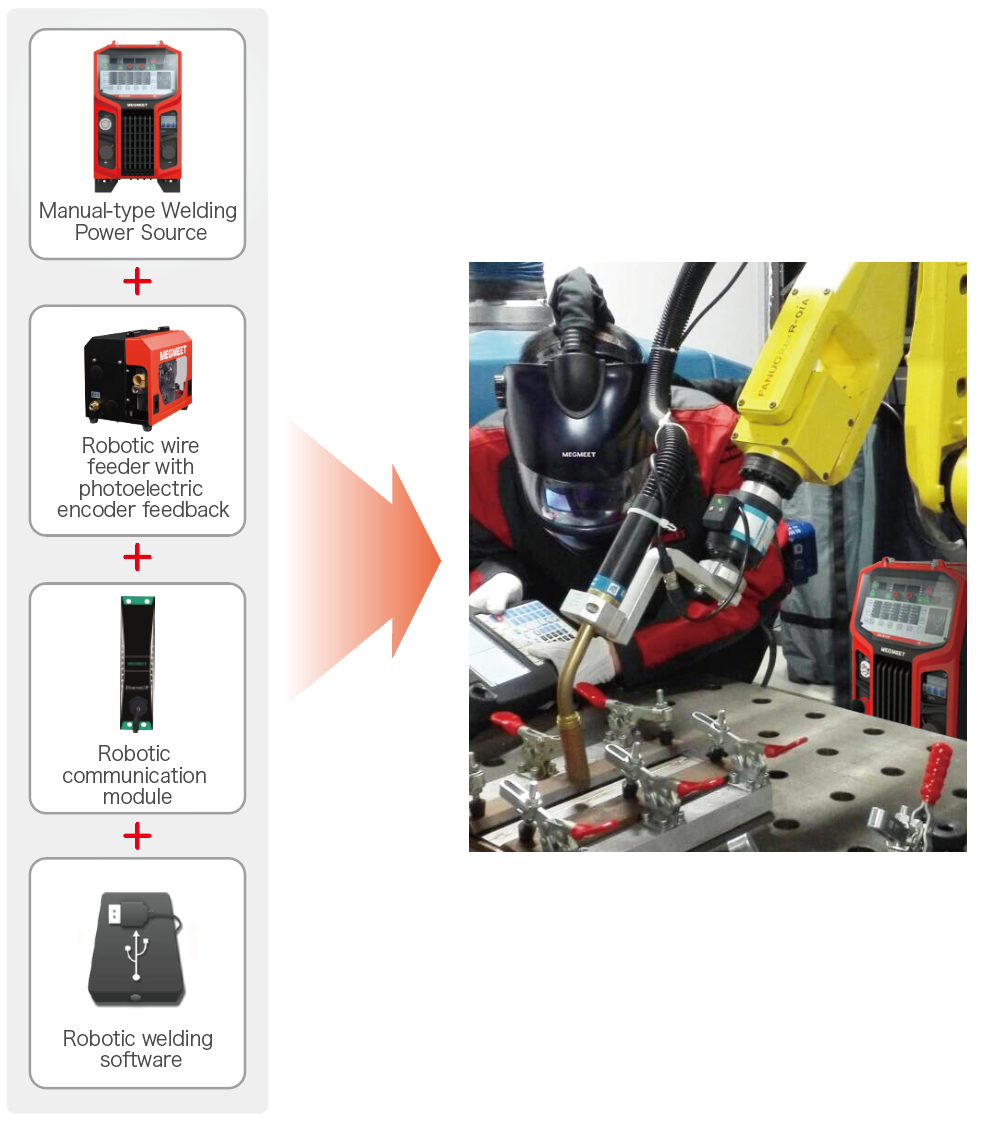

V. Intelligent Manufacturing Upgrading

Manual-type welding machines can be upgraded to a robotic welding power source.

VI. Product Features

Multiple processes integrated into one machine, rich functions to meet various application conditions.

Droplet necking detection and control technology is adopted to automatically clean the end of the wire to improve arc start success rate and quality.

Huge expert welding database, up to 99 groups of welding parameters storage/calling channels, one-key calling, and easy operability;

With a welding current and voltage limiting function, ceiling/floor limits of welding current and voltage can be set to prevent over-standard operation.

Protection functions as input over/under voltage protection, phase loss protection, overheat protection, short circuit protection, and others.

Welding voltage and welding current compensation function to ensure the stability of long-cable welding and ensure the consistency of actual values and preset values.

The heat conduction efficiency of IGBT is increased by 50%, more suitable for long-term, high-intensity, and high-current welding.

Lightning protection level reaches Class D, the wide-range input voltage is more suitable for severe power grids, and can expand to work with oil generators.

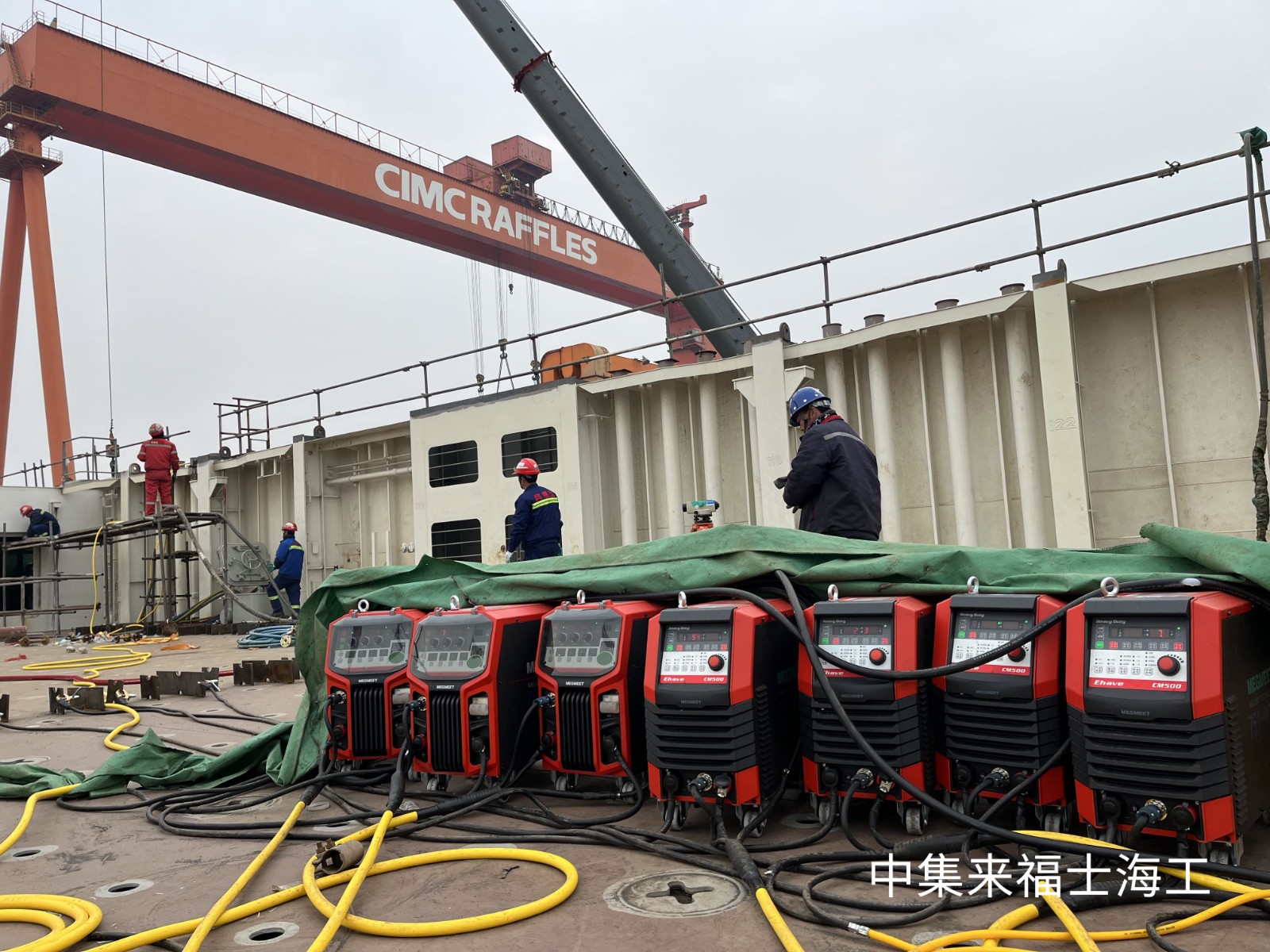

All models of the Ehave-2 series are 100% rated duty cycle, supporting to weld stably at long distances and suitable for industrial heavy-duty harsh environments.