In today’s heavy industrial landscape—from shipbuilding and pressure vessel manufacturing to structural steel erection—productivity is king. Companies are constantly seeking efficient methods to increase throughput, reduce labor costs, and maintain uncompromising quality. When dealing with thick materials and long seams, conventional welding processes often become bottlenecks due to their relatively low deposition rates.

Enter Submerged Arc Welding (SAW).

SAW is a high-efficiency welding process specifically engineered for demanding, heavy industrial applications. Its defining characteristic is its unparalleled ability to achieve remarkably high welding deposition rates, often measured in dozens of pounds per hour. By understanding the core mechanics of SAW and implementing advanced configurations, fabricators can unlock massive productivity gains and achieve a swift return on investment (ROI) in their operations.

This guide will explain the fundamental principles of SAW, detail why it achieves such high material deposition, and outline the applications and strategies necessary to maximize your shop’s efficiency using this powerful process.

I. Understanding the Submerged Arc Welding (SAW) Process

To appreciate SAW’s productivity advantage, one must first grasp its unique operational method, which differs fundamentally from common manual or gas-shielded processes.

1.1. The Basics of SubArc

Submerged Arc Welding is an automated or semi-automated wire-fed process most commonly applied to carbon steels, stainless steels, and various nickel alloys. It is particularly well-suited for materials ranging from half an inch (1/2-inch) to five inches (5-inches) thick, though it can be adapted for thinner material down to 3/16-inch by adjusting travel speed and heat input to prevent burn-through.

The "Submerged Arc" name comes from the fact that the electric arc is completely buried, or submerged, under a blanket of granular, fusible material called flux.

1.2. The Role of Granular Flux

Unlike MIG/MAG or TIG, which use gas to shield the weld pool, SAW utilizes this granular flux. The welding process works as follows:

Flux Delivery: Granular flux is fed onto the joint ahead of the welding torch, creating a thick layer covering the work piece.

Arc Ignition: The arc is struck between the continuously fed electrode wire and the base metal, beneath the blanket of flux.

Shielding and Melting: The arc heat melts the electrode wire, a portion of the base metal, and a portion of the flux. The molten flux forms a protective, conductive slag layer over the molten weld pool, which performs critical functions like degassing, deoxidizing, and alloying.

Weld Solidification: As the travel mechanism moves forward, the molten metal solidifies behind the arc, forming the weld bead. The solidified flux, now a hardened slag crust, peels off easily (if parameters are set correctly), revealing a smooth, clean weld.

1.3. Positional Limitations

Because the process relies on gravity to hold the flux over the joint, SAW can only be used in the flat (1F) and horizontal (2F) welding positions. This makes it ideal for assemblies that can be rotated on positioners or manipulated into the flat position, such as large pipe sections, storage tanks, and structural beams.

II. The Engine of Productivity: Why SAW Achieves High Deposition Rates

Deposition rate is defined as the amount of filler metal melted and fused into the weld joint per unit of time, typically measured in pounds per hour (lb/hr) or kilograms per hour (kg/hr). SAW fundamentally outperforms other arc welding processes due to three synergistic factors: the nature of the arc shielding, the high current capacity, and the capacity for multi-wire systems.

2.1. High Current and 100% Duty Cycles

The first key factor is the process's ability to operate at extremely high currents for extended periods.

Arc Shielding Efficiency: Because the arc is completely buried beneath the flux, the heat energy is intensely focused on melting the electrode wire and base metal. This concentrated thermal efficiency means less heat is wasted, allowing the wire to melt faster.

Massive Current Capacity: SAW systems are often designed with robust power sources capable of operating at 100% duty cycles—meaning they can run continuously without overheating—at currents ranging from 350 amps (for thinner materials) to over 1,000 amps (for thick plates). This is significantly higher than manual or standard semi-automatic processes. Higher current directly translates to a faster melting rate of the electrode wire.

Deposition Metrics: In a standard single-wire SAW setup, deposition rates can easily reach up to 40 pounds per hour. By comparison, a highly skilled manual welder using Shielded Metal Arc Welding (SMAW) typically deposits only 3 to 5 pounds per hour.

2.2. Utilizing Cored Wires for Further Gains

While SAW typically uses solid wire, the option to switch to metal-cored wire provides an additional productivity boost:

Increased Travel Speeds: Cored wires can handle higher currents and offer better arc stability, allowing the operator to increase the speed at which the torch moves along the joint.

Profile Optimization: Metal-cored wires tend to produce a wider, shallower penetration profile compared to solid wire. This characteristic is beneficial for minimizing the risk of burn-through, especially on root passes or materials on the thinner end of the SAW application range, allowing for a faster, more forgiving operation.

Alloying Benefits: Cored wires can include alloying elements to achieve desired mechanical properties, simplifying the overall welding setup by making the flux selection less restrictive.

2.3. Multi-Wire Systems: Tandem and Multiwire SAW

The single greatest leap in SAW productivity comes from configurations that utilize multiple wires fed into the same molten puddle. This maximizes the total current input and deposition capacity.

| Configuration Type | Description | Typical Deposition Rate (Approx.) | Primary Benefit |

SingleWire | The simplest setup; one wire and power source. | Up to 40 Ib/hr |

High quality, basic productivity boost. |

| TwinWire | A single power source feeds two wires side-by-side into a common contact tip. | Up to 60 lb/hr | Higher speed and wider bead profile. |

| TandemWire | Two (or more) independent power sources feed wires in a line (one trailing the other) into the same puddle. | Over 100 Ib/hr | Maximum speed and throughput for long seams. |

Systems featuring tandem SubArc welding (two or more torches arranged in tandem) can push deposition rates to truly extraordinary levels, often exceeding 100 pounds per hour in specialized applications. These high-speed systems are essential for fabrication requiring miles of continuous weld, such as large-diameter pipe and tank construction.

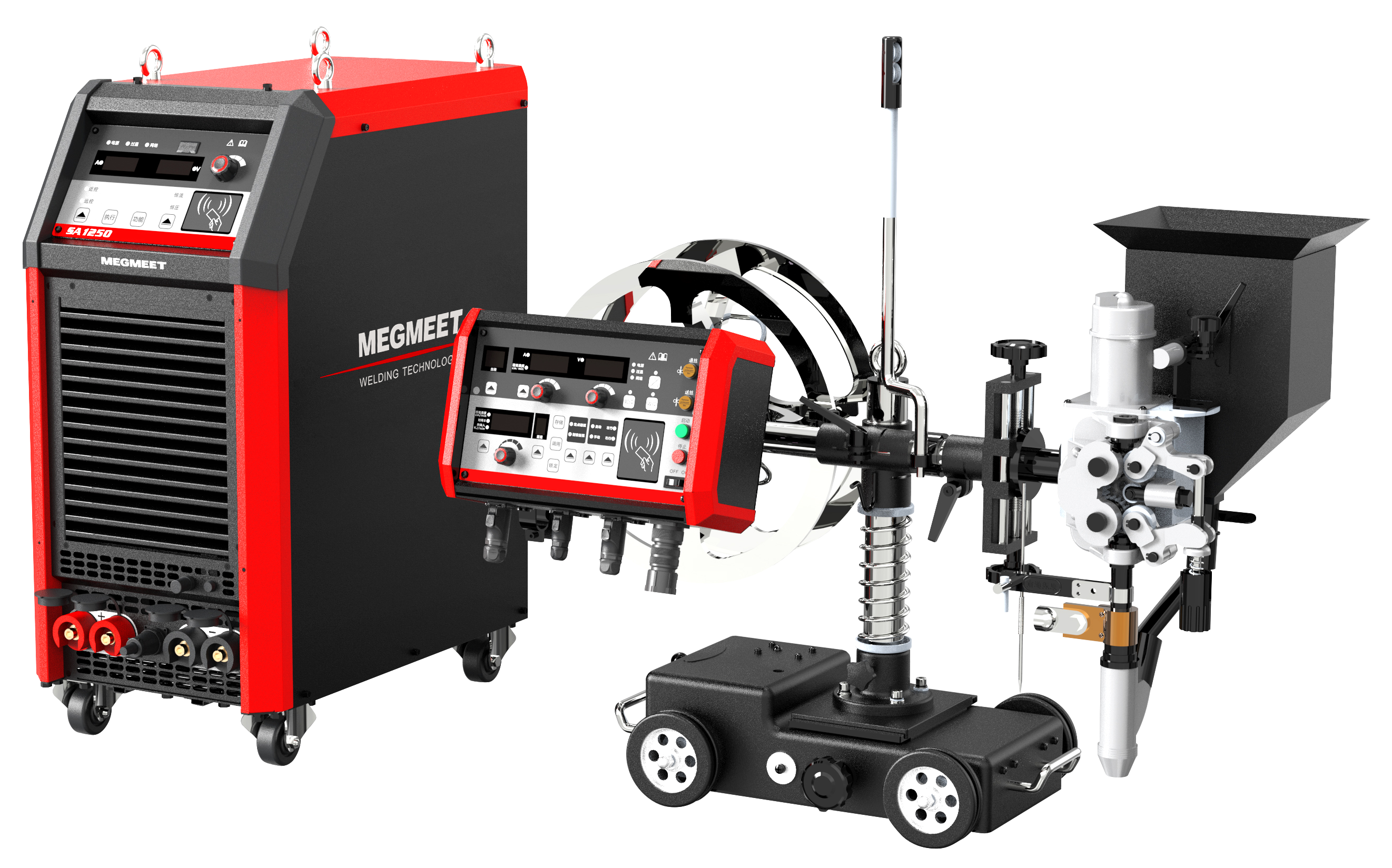

III. Equipment and Setup for Optimized SAW Operations

Achieving top deposition rates requires the correct selection and configuration of equipment, as well as precise parameter control.

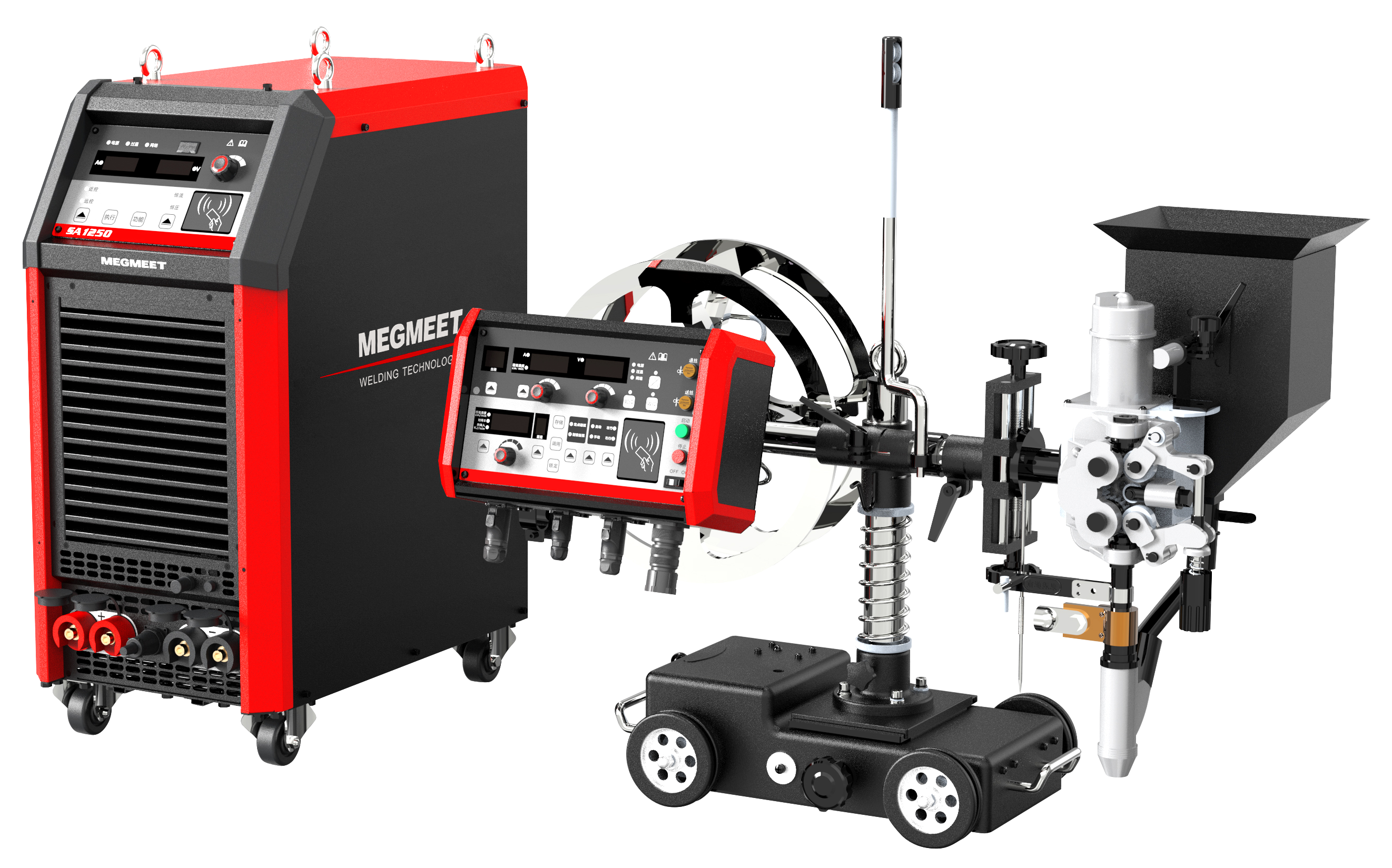

3.1. Power Source Reliability and Versatility

The power source is the heart of the system. In SAW, robust, heavy-duty power sources are essential.

Dual Mode Capability: Modern welding equipment often allows for easy switching between Constant Voltage (CV) and Constant Current (CC) modes, or advanced hybrid modes (like CV+C), which provides maximum flexibility to optimize the arc characteristics based on the joint configuration and desired productivity level.

Digital Integration: The reliability and repeatability of the process are dramatically enhanced by digital control systems. These systems simplify parameter setup, offer remote capabilities, and ensure that complex multi-wire configurations maintain perfect synchronization.

3.2. Consumable Matching: Wire and Flux

In SAW, the wire and the flux are a matched set—they must be classified and qualified together. This combination determines the mechanical properties and metallurgical characteristics of the final weld.

Flux Composition: Fluxes vary in their composition (basicity level), influencing mechanical properties such as impact toughness. The flux’s grain size is also important, as it affects its ability to flow properly through the hopper and be recovered efficiently.

Wire Type: The choice between solid wire and metal-cored wire must be matched with the flux to meet application-specific requirements, such as high strength or high temperature performance. Never mix and match consumables without consulting the manufacturer’s qualified procedures.

3.3. Parameter Control for Quality and Speed

Deposition rates are worthless if the resulting weld fails inspection. The quality and shape of the weld are highly dependent on correctly dialing in the welding parameters:

Parameter | Influence on Weld/Productivity | Optimization Goal |

Welding Current (Amperage) | Dictates penetration depth and melting rate. | Use highest possible current without defect to maximize speed |

| Arc Voltage | Controls the bead width and profile. | Optimize for bead shape and easy slag removal. Too high causes undercut. |

| Travel Speed | The speed of the torch along the joint. | Maximize speed to increase throughput, limited by acceptable heat input and defect formation |

Stickout (Contact Tip to Work)

| Influences resistance heating and deposition. | Longer stickout can increase deposition but may destabilize the arc. |

Polarity

| Affects penetration vs. deposition balance. | Direct Current Electrode Positive (DCEP) yields deeper penetration; Direct Current Electrode Negative (DCEN) yields higher deposition |

By precisely managing these variables, fabricators can achieve a balance between the deepest, strongest weld and the fastest possible travel speed, thereby achieving maximum SAW deposition rates.

IV. Benefits Beyond Speed: Quality, Safety, and ROI

While speed is SAW's main selling point, the process offers significant secondary benefits that contribute to a faster ROI.

4.1. Superior and Consistent Weld Quality

Since SAW is primarily an automated process, the variables are controlled by the machine, not the operator’s hand:

Repeatability: Automated travel speed, wire feed speed, and voltage ensure that every inch of weld is laid down under near-identical conditions, leading to excellent, repeatable weld quality.

Minimal Defects: The consistent, steady arc results in very low spatter (reducing post-weld cleanup labor) and minimal weld fume.

Deep Penetration: The high heat input capability allows for deep penetration, which is vital for achieving the strength required in thick materials with fewer passes, thereby saving time.

4.2. Improved Operator Comfort and Safety

The absence of an open arc and the presence of low fume levels create a vastly superior work environment compared to manual processes.

No Flash: The flux completely submerges the arc, eliminating arc flash exposure and the need for conventional welding helmets.

Low Fume: Fume generation is minimal because the flux captures most of the metallic vapor.

Ergonomics: Since the operation is automated, the operator is not required to be bent over the work piece, improving comfort and reducing strain during long periods of welding.

4.3. Rapid Return on Investment (ROI)

Doubling or Tripling Throughput: An operation can often double or triple its welding throughput by converting high-volume, long-seam work to SAW.

Efficient Labor Use: Because the system runs autonomously once set up, one operator can monitor a single or even multiple systems, freeing up highly skilled welders for specialized manual work.

Reduced Rework: The consistency and high quality of the process translate directly to reduced rework and repair costs, which are often the hidden drain on profitability in manual operations.

FAQs on Submerged Arc Welding

Q1: Is Submerged Arc Welding only for very thick metals?

A: No, that is a common misconception. While it is excellent for thick materials (up to 5 inches), SAW can be used on materials as thin as 3/16-inch. The key is to manage the travel speed and heat input very carefully to prevent burn-through, especially on the thin end of the spectrum.

Q2: Does the high deposition rate of SAW make the weld less strong?

A: No. The strength and mechanical properties of the weld are determined by the precise metallurgical compatibility and chemistry of the flux and wire combination, not just the speed. When the process is set up correctly, following a qualified Welding Procedure Specification (WPS), SAW delivers welds that meet or exceed the requirements for strength and toughness in demanding applications.

Q3: How do I choose between Constant Voltage (CV) and Constant Current (CC) for SAW?

CV (Constant Voltage): Best for single-wire applications where deposition speed and consistent bead profile are prioritized. It is more tolerant of variations in stickout.

CC (Constant Current): Often preferred for multi-wire or tandem operations and deep-penetration applications. It provides better control over the penetration depth. Modern, digitally controlled machines often simplify this choice or offer synergistic modes that provide benefits of both.

Q4: What is flux recovery, and why is it important for efficiency?

A: Flux recovery is the process of vacuuming and filtering the unused, unfused granular flux surrounding the weld bead so that it can be reused in future welds. Proper flux recovery equipment reduces material waste, lowers consumable costs, and contributes to the overall cleanliness and efficiency of the welding cell.

Conclusion: Welding the Future with High Deposition

Submerged Arc Welding is far more than an alternative welding process; it is a critical tool for businesses competing in the heavy industrial market. The process provides a unique combination of extreme deposition rates, reliable quality, and enhanced operator safety.

By strategically adopting SAW, particularly with multi-wire and cored wire configurations, fabricators can radically transform their operations, overcome productivity bottlenecks, and secure a powerful competitive advantage. The ability to deposit massive volumes of filler metal in a clean, consistent manner ensures that the investment in SAW technology is one of the most effective strategies available for maximizing welding productivity and profitability.

Related articles:

1. Don't Rush to Choose! Distinguish SAW and GMAW Welding First!

2. An In-depth Guide to Submerged Arc Welding (SAW) & Its Industrial Applications

3. Key Differences of SAW VS. SMAW and Which One to Choose?

4. Blow Holes Defect in Submerged Arc Welding: Causes & Solutions

5. In-Depth Analysis of 8 Common Defects in Submerged Arc Welding