Laser welding has moved rapidly from niche applications into mainstream manufacturing — yet many questions still arise among engineers, purchasing teams and end-users. This article addresses the most common questions about laser welding: what it is, when to use it, how it compares to other methods, what the pitfalls are, and what to watch out for when selecting or specifying equipment. If you’re working in precision manufacturing, automation, or industrial welding procurement, this guide is written for you.

I. What is laser welding?

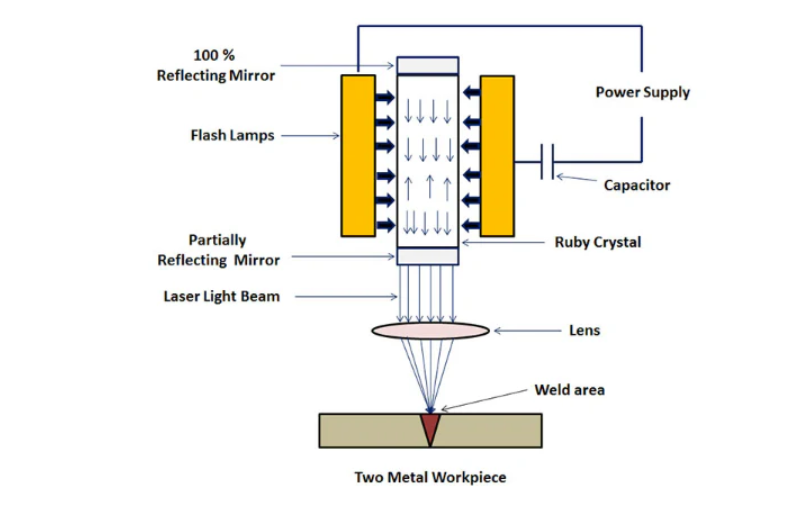

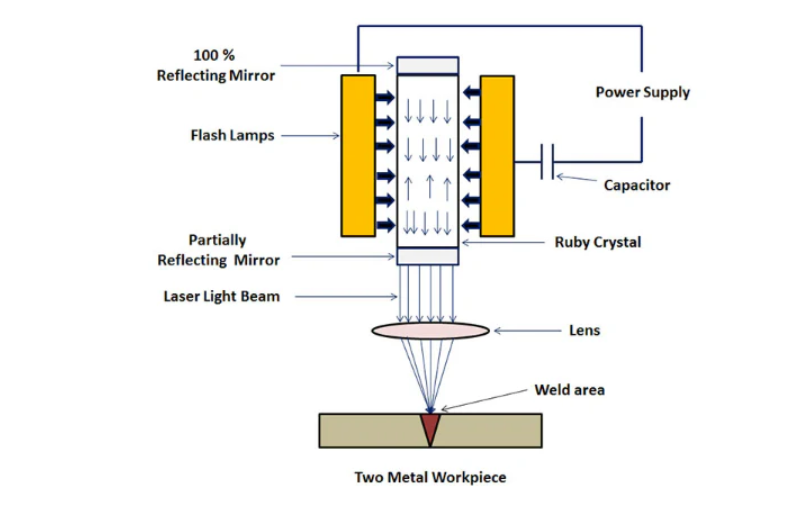

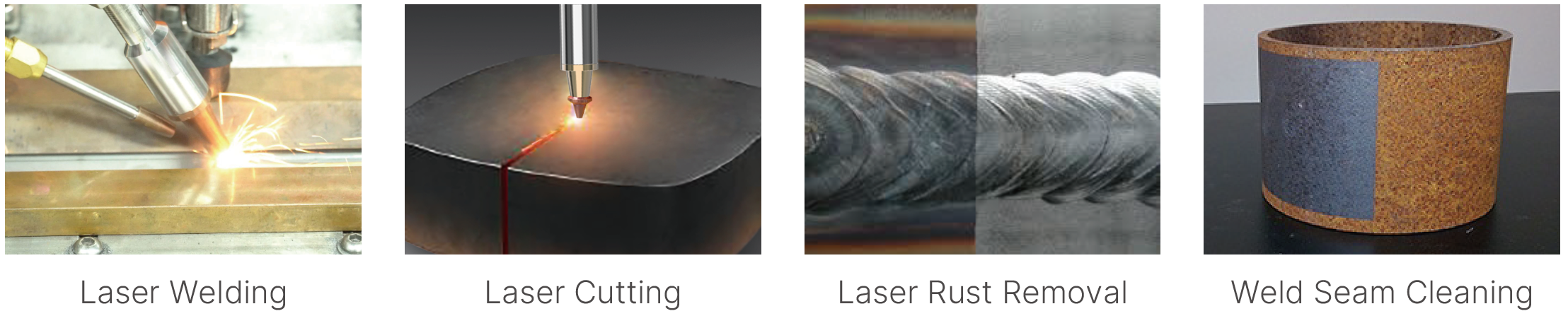

Laser welding (sometimes termed laser-beam welding) uses a concentrated laser beam as the heat source to melt and join parts. The beam is focused to a tiny spot, producing high power density. When applied to a joint, this enables melting and fusion of the component surfaces, under controlled conditions. (See a schematic of the principle.)

Laser welding is characterised by:

High power density and thus high energy concentration

Possibility of deep penetration welds or very fine welds with minimal heat-affected zone

Application to a wide range of materials (metals, some plastics/composites)

Use of specialised optics, beam delivery systems, shielding gas, and often automation or robot integration.

In short: if you need clean welds, minimal distortion, or welds in an automated environment, laser welding is often a strong candidate.

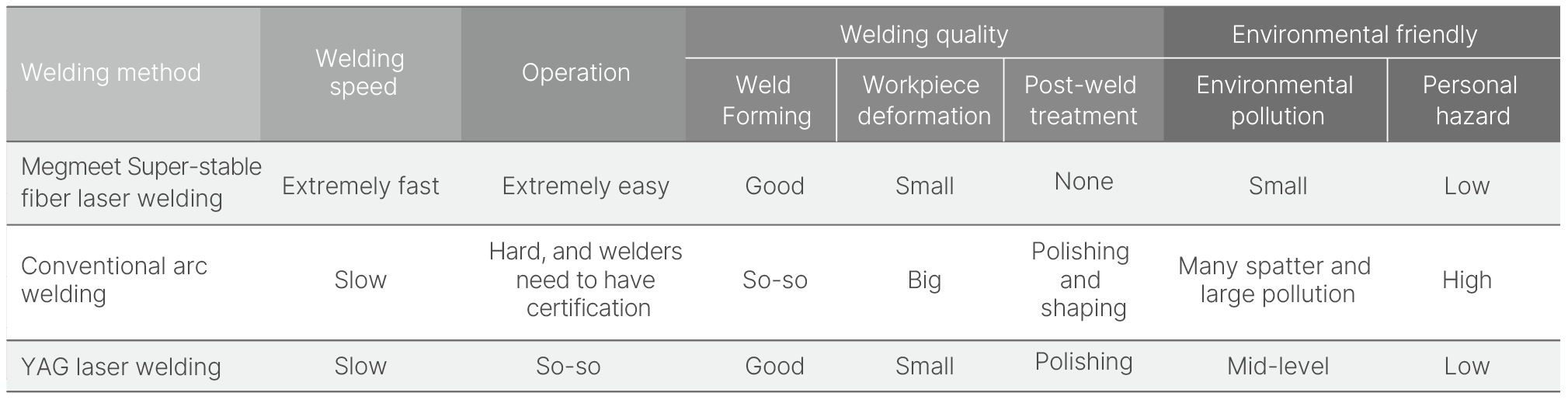

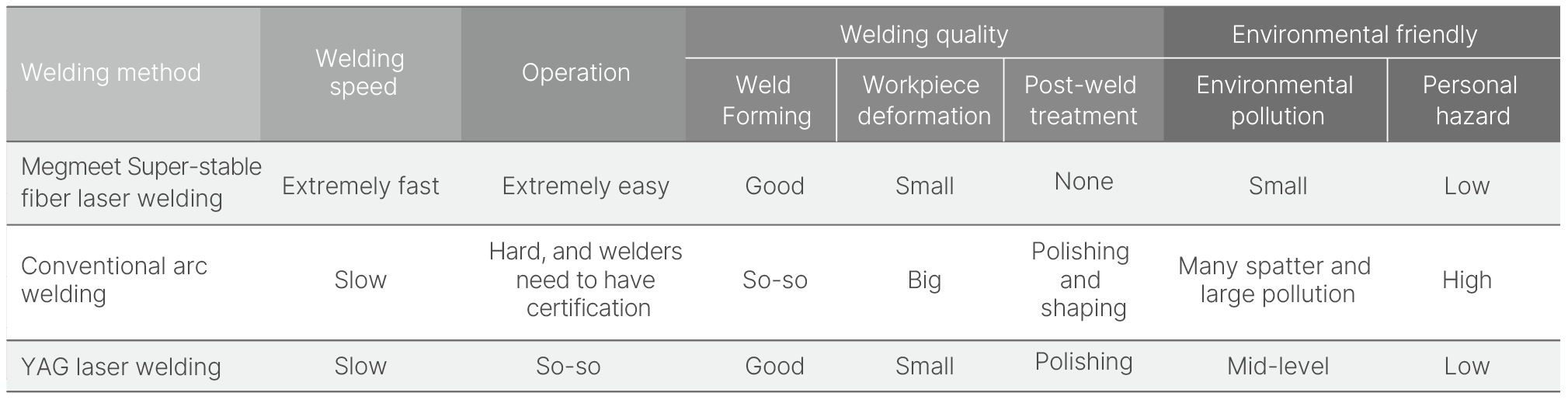

II. Why consider laser welding instead of traditional arc welding?

Here are some of the key advantages and also some limitations so you can compare appropriately.

1) Advantages:

Precision and minimal HAZ: Because the laser beam is highly focused, the heat‐affected zone (HAZ) can be very narrow. That means less warpage and fewer post-weld finishing operations.

High speed / productivity: Laser welding can achieve high travel speeds and penetration, especially in keyhole mode (see later).

Automation friendly: Lasers integrate well with robots, beam-delivery systems, and process monitoring.

Wide material capability: Many metals (and even some plastics) can be joined.

2) Limitations / Considerations:

Initial cost and system complexity: Laser systems tend to have higher capital cost than many arc welders. Some sensor/optics/beam-delivery systems are delicate and require vigilance.

Fit-up, joint cleanliness and preparation matters: Laser welding often demands tighter tolerances, cleaner surfaces, and proper alignment.

Material considerations: Highly reflective or high-thermal-conductivity materials (e.g., copper, aluminium) pose additional challenges.

Safety & monitoring: The beam is intense, sometimes invisible, reflections matter, fume generation still exists. Monitoring/maintenance is still required.

III. FAQs of Laser Welding — clear, practical answers

1) Are laser welders prohibitively expensive?

Short answer: the upfront cost is higher than basic arc welders, but the total cost of ownership can be favorable. Laser welding cuts cycle time, reduces post-processing and rework, and enables automation — all of which can produce a payback period measured in months to a couple of years depending on volume and part complexity. Lower-power and handheld lasers have further reduced the entry cost for small shops.

2) What types of lasers are used?

The common types are fiber lasers, CO₂ lasers, and solid-state (e.g., Nd:YAG) lasers. Today, fiber lasers dominate many manufacturing uses because of compactness, efficiency, beam quality, and ease of fiber delivery to the work area. Different lasers have distinct traits (wavelength, coupling to materials, maintenance needs) that influence their use.

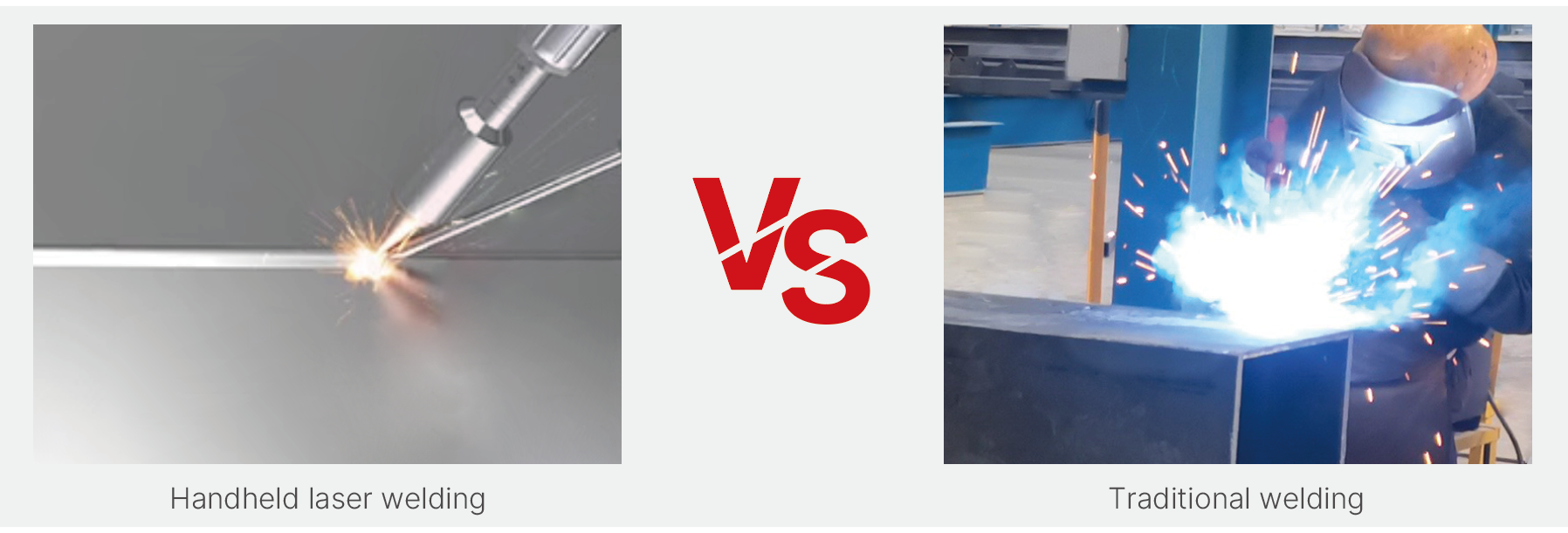

3) Can handheld laser welders handle production work?

Yes — handheld and compact laser welders have made laser welding accessible for repair work, small-batch fabrication, and even some production tasks. They’re especially useful for on-site repairs (jewelry, tool repair, bodywork) and for small fixtures where a full automated cell isn’t justified. For high-volume, repeatable parts, stationary/automated systems usually deliver better consistency.

4) Which materials can you laser-weld?

Metals that weld well with lasers include stainless steel, carbon steel, many tool steels, and some alloys of nickel and titanium. Aluminum and copper are weldable, but their high reflectivity and thermal conductivity make process tuning more challenging; specialized wavelengths or surface preparation help. Plastics and some dissimilar material joints are possible with the right laser type and fixturing.

5) Is laser welding only for thin sheets?

No. While lasers are excellent for thin materials and delicate work because of low distortion, modern high-power lasers can weld thick sections too — by increasing power and controlling travel speed and focus to form deep keyhole welds. The application, part geometry, and joint access dictate the practical thickness limits.

6) Does “more power = better weld”?

Not necessarily. Excessive power can cause blow-through, large spatter, or poor fusion geometry. The key is matching power, spot size, pulse/continuous mode, and speed to the joint and material. Often lower power with better focus and optimized travel speed gives superior quality for thin parts.

7) How big is the heat-affected zone (HAZ)?

Laser welding is known for a narrow HAZ compared with many arc processes because the energy is concentrated. That makes lasers attractive where thermal distortion or material property changes must be minimized (e.g., electronics housings, medical components). HAZ size depends on power, speed, and focal conditions.

8) Do lasers need shielding gas like TIG?

Yes — many laser welding operations use shielding gas (argon, helium, or mixes) to keep the molten pool free of oxygen and nitrogen, avoid porosity, and improve weld appearance. Gas requirements depend on material and application; some setups use gasless methods with specialized optics, but gas remains common in production.

9) What about surface preparation?

Surface cleanliness is crucial. Oils, paint, oxide layers, or heavy contaminants reduce absorptivity and can spoil weld quality. For reflective metals (copper, aluminum), mechanical roughening or coatings sometimes help initial absorption. Proper fixturing and consistent part prep make parameter development much easier.

10) Are there safety concerns?

Yes — lasers present eye and skin hazards and can generate fumes and particulates. Proper engineering controls, interlocks, beam enclosures, laser-rated eyewear, fume extraction, and operator training are required. Don’t treat laser systems as “set and forget”; safe operation and routine maintenance are mandatory.

11) Do lasers need a lot of maintenance?

They do require preventive maintenance — optics cleaning, beam alignment checks, cooling system service, and fiber/connector inspections. Modern fiber lasers are generally lower maintenance than older gas-laser systems, but periodic checks and monitoring prolong component life and maintain beam quality.

12) What causes porosity or weak welds in laser welding?

Common causes include improper shielding gas, surface contamination, wrong focal position, excessive travel speed, or incorrect pulse shaping (for pulsed systems). Process development (welding trials, cross sections, and NDT) helps identify the root cause and produce robust parameters.

13) Can laser welding be automated?

Yes — lasers integrate exceptionally well with robots and motion systems. Automation increases throughput, repeatability, and traceability, but it doesn’t eliminate the need for skilled operators and process monitoring. Automated setups still require calibration, fixturing, and quality checks.

14) How do I choose the right laser or system?

Consider:

Application & production volume (repair vs high-volume part)

Materials & thickness (copper/aluminum needs special attention)

Weld geometry & access (handheld vs fixed head vs robot)

Pulse vs CW (pulse is common for spot welding or jewelry; CW for deep fusion)

Support & service (spares, optics, cooling)

Run application trials with representative parts before committing — real parts reveal fixturing, access, and joint issues that specs alone don’t show.

15) How long does it take to learn laser welding?

A welder experienced with arc processes picks up laser welding fundamentals quickly, but competent operation requires training on equipment, safety, and parameter development. Short, focused courses and hands-on trials accelerate learning; however, developing robust production parameters and troubleshooting skills takes practice.

IV. Practical tips for getting started

Start with representative coupons and iterate parameters (power, focus, speed).

Keep surfaces clean and repeatable.

Use weld cross-sections early in development to verify penetration and HAZ.

Implement fume extraction and laser safety protocols from day one.

Consider a trial or demo from vendors and, if possible, test a handheld unit for repairs before buying a production cell.

Conclusion

Laser welding is flexible: from fine jewelry repairs to high-speed production joins and thick-section structural work. It requires upfront investment and disciplined process development, but its precision, speed, and low distortion make it a powerful tool in modern manufacturing. Use the FAQs above as a practical checklist when evaluating laser welding for your shop or project.

Related articles:

1. What protective gas should I use for laser welding?

2. Laser Welding: Which Materials Can You Weld?

3. Spot Size, Laser Quality and Welding Performance

4. Pulsed vs. CW Laser Welding: Key Differences | Expert Insights

5. 2023 Top 5 Rated Laser Welders & Welding Machines for Sale