If you want to weld thin metals like a pro, you might want to try pulsed TIG welding. Pulsed TIG welding is a modified version of TIG welding, in which the welding current alternates between a high and a low level at a selected frequency. This technique has many benefits, such as:

Controlling the heat input and reducing the risk of warping, burn-through, discoloration, and corrosion.

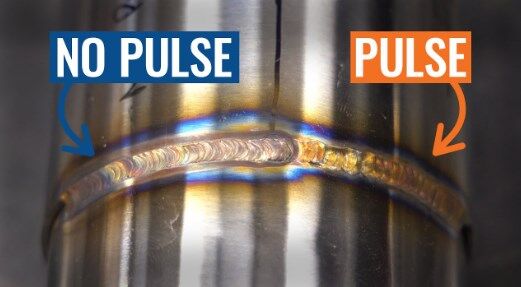

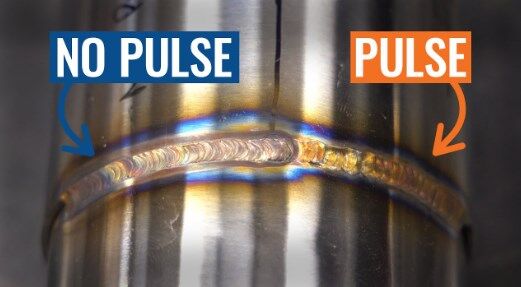

Improving the weld penetration and appearance.

Creating a smooth and consistent bead profile.

Enabling welding in all positions and on different materials.

In this blog post, I will explain what pulsed TIG welding is, how it works, how to set it up, and when to use it. Let’s get started!

I. What is pulsed TIG welding?

TIG welding, or tungsten inert gas welding, is a process that uses a non-consumable tungsten electrode to create an arc and heat the base metal. A shielding gas, usually argon, protects the weld pool from contamination. A filler metal may or may not be added, depending on the application.

Pulsed TIG welding is a variation of TIG welding, where the welding current is not constant, but switches between two levels: a peak current and a base current. The peak current is the maximum amperage output that melts the metal and creates the weld. The base current is the minimum amperage output that maintains the arc and allows the weld pool to solidify. Learn What Is Pulse Welding? And What Do You Use It For?

The frequency of switching between the peak and the base current is called the pulse frequency, and it is measured in pulses per second (Hz). For example, a pulse frequency of 100 Hz means that the current switches 100 times per second. The duration and amplitude of both the peak and the base current can be adjusted independently to suit the job.

Some TIG welders also allow modifying the portion of the peak and the base current per pulse. This is called the pulse time on or the pulse duty cycle, and it is expressed as a percentage. For example, a pulse time of 50% means that the peak current lasts for 50% of the pulse duration, and the base current lasts for the remaining 50%.

To learn about Pulsed MIG welding, you can read the article MIG, Pulsed MIG, and Double Pulsed MIG Explained.

II. How does pulsed TIG welding work?

The main idea behind pulsed TIG welding is to control the heat input and the weld pool size by varying the current output. When the peak current is applied, the metal melts and forms the weld. When the base current is applied, the metal cools down and solidifies. This cycle repeats at a rapid rate, creating a series of overlapping melt spots that form a continuous weld. Read Pulse Welder: A New Technology for High-Quality Welding.

By using pulsed TIG welding, you can achieve several advantages, such as:

Reducing the heat input and the heat-affected zone, which minimizes the distortion and deformation of thin metals.

Improving the weld penetration and the fusion between the base metal and the filler metal, which enhances the strength and quality of the weld.

Creating a smooth and consistent bead profile, which improves the appearance and reduces the need for post-weld grinding and finishing.

Enabling welding in all positions and on different materials, such as aluminum, stainless steel, titanium, and copper.

III. How to set up pulsed TIG welding?

To set up pulsed TIG welding, you need a TIG welder that has a pulse function, a tungsten electrode, a shielding gas, and a filler metal (optional). You also need to prepare the metal by cleaning it and removing any dirt, oil, or oxide layer.

The main parameters that you need to adjust for pulsed TIG welding are:

The peak current: This is the maximum amperage output that determines the weld penetration and the size of the weld pool. The peak current should be high enough to melt the metal, but not too high to cause burn-through or excessive spatter. A general rule of thumb is to use 1 amp per 0.001 inch of metal thickness. For example, if you are welding a 0.062-inch thick aluminum sheet, you can use a peak current of 62 amps.

The base current: This is the minimum amperage output that determines the cooling rate and the solidification of the weld pool. The base current should be low enough to allow the metal to cool down, but not too low to lose the arc stability. A general rule of thumb is to use 10% to 30% of the peak current as the base current. For example, if you are using a peak current of 62 amps, you can use a base current of 6 to 18 amps.

The pulse frequency: This is the number of pulses per second that determines the speed and the appearance of the weld. The pulse frequency can range from 0.5 Hz to 500 Hz, depending on the application and the preference of the welder. A low pulse frequency (below 10 Hz) creates a distinct ripple pattern on the weld bead, which some welders find aesthetically pleasing. A high pulse frequency (above 100 Hz) creates a smooth and uniform weld bead, which some welders find easier to control. A medium pulse frequency (between 10 Hz and 100 Hz) offers a balance between the two extremes.

The pulse time: This is the percentage of the peak current per pulse that determines the heat input and the weld pool size. The pulse time can range from 10% to 90%, depending on the application and the preference of the welder. A low pulse time (below 50%) reduces the heat input and the weld pool size, which is suitable for welding thin metals and preventing burn-through. A high pulse time (above 50%) increases the heat input and the weld pool size, which is suitable for welding thick metals and improving penetration.

IV. When to use pulsed TIG welding?

Pulsed TIG welding is a versatile technique that can be used for various applications and materials. However, some situations where pulsed TIG welding is especially beneficial are:

When welding thin metals, such as aluminum, stainless steel, or titanium, they are prone to warping, burn-through, discoloration, and corrosion. Pulsed TIG welding can reduce the heat input and the heat-affected zone, which preserves the mechanical and chemical properties of the metal.

When welding in vertical or overhead positions, where gravity can cause the weld pool to sag or drip. Pulsed TIG welding can control the weld pool size and the solidification rate, which prevents the metal from falling out of the joint.

When welding dissimilar metals, such as copper and steel, they have different melting points and thermal conductivities. Pulsed TIG welding can adjust the heat input and the penetration for each metal, which ensures a good fusion and a strong bond.

V. Conclusion

Pulsed TIG welding is a modified version of TIG welding that uses a pulsing current to control the heat input and the weld pool size. This technique has many benefits, such as improving the weld penetration, appearance, and quality, as well as enabling welding in all positions and on different materials. To set up pulsed TIG welding, you need to adjust the peak current, the base current, the pulse frequency, and the pulse time, depending on the application and the preference of the welder. Pulsed TIG welding is especially useful for welding thin metals, welding in vertical or overhead positions, and welding dissimilar metals.

Related articles:

1. Testimony of Excellence: MEGMEET DEX PM3000 Pulse Welding Machine Review

2. Why Choose a Pulse Welding Machine: Insights from Experts

3. Pulse Function of Welders & Pros and Cons of Pulse Welding

4. Pulsed Welding Technology: Solution to Sheet Metal Burn-Through

5. Pulse Technology’s Role in Enhancing Efficiency and Precision