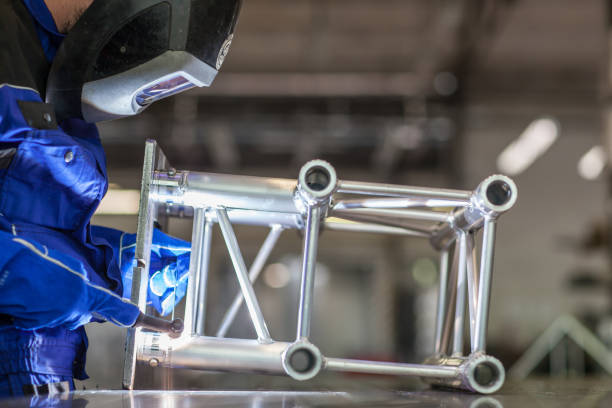

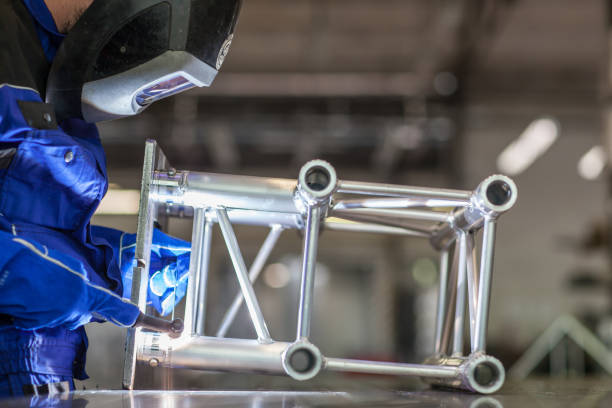

Aluminum is one of those metals that can really test a welder’s patience. It’s lightweight, corrosion-resistant, and widely used in everything from aerospace frames to automotive parts—but when it comes to welding, it can be unforgiving. Gas Tungsten Arc Welding (GTAW), often called TIG welding, is one of the most reliable ways to weld aluminum. But to do it right, especially when using alternating current (AC), there are a handful of critical factors you simply can’t ignore.

This article takes a deep dive into how GTAW with AC works for aluminum, what settings and techniques matter most, and how to get clean, strong welds without driving yourself crazy in the process.

I. Understanding GTAW for Aluminum Welding

GTAW relies on an electric arc formed between a non-consumable tungsten electrode and the workpiece. A shielding gas, usually argon or an argon-helium mix, protects the weld pool from contamination. Unlike processes that use consumable electrodes, GTAW gives the welder precise control over heat input, puddle size, and filler addition.

Aluminum, however, brings special challenges. Its high thermal conductivity pulls heat away from the weld zone faster than steels do. Its surface is covered by a tough oxide layer (aluminum oxide) that melts at a much higher temperature than the base metal underneath. These two properties alone mean that the arc must both break through the oxide layer and deliver enough heat for full penetration—all while avoiding burn-through. That’s where AC welding and specific settings like high-frequency stabilization and balanced wave control come in.

II. High-Frequency Stabilization: Keeping the Arc Alive

Anyone who has tried welding aluminum with GTAW knows the arc likes to flicker or snuff out right when you don’t want it to. That’s because in AC welding, the current crosses zero twice every cycle. Without help, the arc would extinguish during these zero-crossing points.

High-frequency (HF) stabilization solves this. Think of HF as a spark assist system that keeps the arc alive when the main current is temporarily at zero. Most GTAW machines give three choices:

Start Mode – Delivers a short burst of HF to get the arc going without electrode contact. Commonly used in DC welding.

Continuous Mode – Keeps HF running during the entire weld. This is the go-to setting for AC aluminum welding because it prevents the arc from cutting out every half cycle.

Off Mode – No HF at all, requiring scratch or touch starts. Not recommended for aluminum GTAW, since it risks electrode contamination.

For aluminum, continuous high-frequency is usually the safe bet. It creates a stable arc, prevents frustration mid-weld, and makes sure your bead doesn’t look like a patchwork of starts and stops.

III. Balanced Wave and Square Wave Technology

The waveform of the AC current is another critical piece of the puzzle. With traditional sinusoidal AC, the electrode spends equal time in negative (EN) and positive (EP) polarity. But aluminum welders soon discovered that not all tasks need a perfect 50/50 split.

Electrode Negative (EN) focuses heat into the workpiece, giving penetration.

Electrode Positive (EP) scrubs away the oxide layer on the surface, providing cleaning action.

Balanced wave control allows the welder to adjust how much time the arc spends in each half of the cycle. If your weld requires deeper penetration—say, a thick aluminum plate—you extend the EN time. If you’re dealing with dirty or heavily oxidized material, you increase EP to boost cleaning.

Modern GTAW machines go a step further with square wave technology. Instead of a smooth sine wave, the machine produces a sharp square-shaped cycle. This lets the arc transition almost instantly between EN and EP, reducing instability around the zero crossing. The result is a crisp, snappy arc that feels more responsive and delivers both better penetration and cleaning.

For welders, this means less time fighting the arc and more time focusing on bead placement and puddle control.

IV. Torch Handling: Angles, Movement, and Bead Control

Technique is just as important as settings. Even the best machine can’t fix sloppy torch work.

Grip: Hold the torch like a pencil for control. Rest your hand lightly on the work surface to steady movements.

Angle: In most flat-position welds, tilt the torch about 10° forward in the direction of travel. This slight push angle directs shielding gas into the puddle and improves visibility.

Filler Wire Feeding: Keep filler wire short—no more than 6–8 inches sticking out from your fingers. Longer extensions wobble and can contaminate the weld. Feed the wire smoothly with a thumb-and-finger motion, always adding it just ahead of the puddle.

Consistency is everything here. Jerky wire feeding or uneven torch angles cause porosity, lack of fusion, or messy bead appearance. Smooth, steady motion ensures the puddle wets out evenly and filler distributes where it’s supposed to.

V. Choosing the Right Tungsten Electrode

For AC GTAW welding of aluminum, electrode choice is a critical variable. The tungsten type affects arc stability, current capacity, and how well the oxide layer is removed during welding.

Pure Tungsten (Green): Containing at least 99.5% tungsten, this electrode forms a clean, rounded “balled” tip under AC. That rounded tip spreads the arc evenly, providing effective oxide cleaning and good stability. Its drawback is limited current-carrying capacity—push it too hard and it overheats or deforms—so it’s better suited for lighter work or thin aluminum.

Zirconiated Tungsten (White): Alloyed with zirconium oxide, this electrode resists contamination and splitting, even at higher amperages. It delivers arc stability close to pure tungsten but can handle much heavier current loads. Because of its durability and resistance to tungsten spitting, zirconiated tungsten is widely preferred for critical aluminum welds, including applications requiring radiographic-quality joints.

Ceriated Tungsten (Grey/Orange): With about 2% cerium oxide added, ceriated tungsten maintains a stable arc at low to medium currents and reduces electrode burn-off. It behaves much like pure tungsten but with longer service life and less risk of contamination. On aluminum, it performs well in balanced wave AC machines and is particularly useful on thin material where precise puddle control matters.

Thoriated Tungsten (Red): A strong performer in DC welding on steels, thoriated tungsten can handle high amperage but does not maintain the rounded ball shape needed for aluminum AC welding. Because of that, it’s not recommended for aluminum applications.

In practice: Pure tungsten is fine for light-duty work, zirconiated offers the best balance for heavy-duty or high-quality welds, and ceriated works well for precision or low-current aluminum applications.

VI. Cold Wire Feeders: A Helping Hand

Hand-feeding filler rod can be steady work for short welds, but on long runs or in production welding, fatigue and inconsistency creep in. Cold wire feeders solve this problem by automating the delivery of filler wire, giving the welder a consistent feed while freeing up focus for torch manipulation.

Cold wire feeders can be integrated into manual, semi-automatic, or fully automated GTAW setups. They work with both hard and soft wires, though aluminum requires special care due to its softness. Smooth U-grooved drive rolls are essential, since V-grooved rolls tend to crush or deform aluminum wire. The filler is guided through a conduit with a liner that must be clean and matched to the wire diameter. Worn or contaminated liners lead to erratic feeding and should be replaced promptly.

Modern systems offer precise feed control. Older feeders may use rheostats for basic adjustment, but digital tachometer-driven units provide accurate speed regulation and real-time readouts, ensuring filler enters the puddle at a steady rate. This is especially important for aluminum, where too much wire overwhelms the molten pool, while too little results in underfill or lack of fusion.

Key Advantages:

Consistency: Every bit of filler is delivered at the same pace, improving bead appearance and reducing porosity.

Efficiency: Welders can maintain focus on torch angle and puddle control, particularly valuable in long welds.

Productivity: In high-volume work such as shipbuilding, automotive, or aerospace, feeders reduce operator fatigue and raise throughput.

Troubleshooting: Birdnesting at the drive rolls often indicates excessive drive pressure or a damaged liner. Irregular feed suggests dirt or wear in the liner. Burnback, where the filler fuses to the tungsten, usually points to feed speed set too high.

In short, cold wire feeders are more than just a convenience—they’re a practical solution for achieving consistency, reducing fatigue, and meeting the strict quality demands of aluminum welding.

VII. Additional Tips for Successful Aluminum GTAW with AC

Clean the Base Metal Thoroughly – Aluminum’s oxide layer is your biggest enemy. Wire brush with stainless steel dedicated only to aluminum, or use chemical cleaners.

Preheat for Thick Sections – For plates over about 12 mm, preheating to 150–200°C can reduce cracking and improve fusion.

Use Proper Shielding Gas Flow – Around 15–20 cubic feet per hour is typical. Too much flow causes turbulence, sucking in air; too little leaves the puddle unprotected.

Watch Your Heat Input – Aluminum is quick to overheat and warp. Keep travel speeds steady and avoid dwelling in one spot too long.

Practice, Practice, Practice – GTAW on aluminum is as much about muscle memory as it is about science. Small improvements in consistency make a big difference in bead quality.

Conclusion

Welding aluminum with GTAW on alternating current isn’t the easiest task in the world, but once you understand the critical factors—high-frequency stabilization, balanced wave control, torch handling, electrode selection, and filler feeding—it becomes a lot more manageable. Aluminum may demand more attention and finesse than steel, but the payoff is worth it: strong, clean welds that hold up in demanding applications.

If you’re serious about mastering it, don’t just rely on machine settings—develop a steady hand, practice often, and learn how to read the puddle. With time, AC GTAW welding of aluminum can go from a frustrating challenge to one of the most rewarding skills in your toolbox.

Related articles:

1. 3 Common Types of Welding Techniques Used for Aluminum

2. How to Weld Aluminum with Inverter-Based Power Supplies?

3. How to TIG Weld Aluminum: A Beginner's Guide

4. 15 Tips for Welding Aluminum in Shipbuilding Industry

5. A Complete Comparison of Aluminum Welding and Steel Welding