BUS – Megmeet's Exclusive Welding Partnership in the Netherlands

Megmeet Welding Technology is proud to announce its exclusive partnership with BUS – Industrial Tools, a leading distributor of welding and industrial automation equipment in the Netherlands. This strategic alliance brings together Megmeet’s advanced digital welding technology and BUS’s decades of experience in industrial tools, welding systems, and process optimization to deliver smarter, more efficient, and more reliable welding solutions to customers across the Benelux region.

I. About BUS – Industrial Tools

BUS – Industrial Tools, found in 1957, is a trusted supplier of industrial tools, welding equipment, and technical service solutions across the Netherlands and Belgium.

For over six decades, BUS has supported industries in metal fabrication, mechanical engineering, ship construction, and industrial maintenance, offering complete systems and expert advice to improve production performance.

Key areas of expertise include:

Welding technology distribution (MIG/MAG, TIG, MMA, plasma, and laser systems)

Robotic and automation integration for high-volume welding lines

Industrial tooling and MRO solutions for production facilities

After-sales service, calibration, and technical training

Process consulting and productivity optimization

BUS is known for its customer-oriented approach, technical knowledge, and long-standing relationships with Europe’s top manufacturers. The company’s extensive service network and local inventory ensure fast delivery and on-site support for industrial clients throughout the region.

II. Benefits of the Megmeet–BUS Partnership

This partnership combines Megmeet’s cutting-edge welding technology with BUS’s strong local presence and service capabilities to deliver complete, future-ready welding solutions.

Key advantages for customers:

Exclusive access to Megmeet welding systems in the Netherlands and Belgium, including inverter-based MIG/MAG machines, multi-process welders, and robotic power sources.

Comprehensive automation solutions, integrating power sources, wire feeders, torches, and digital controllers for robotic or manual welding applications.

Local sales and technical support through BUS, ensuring quick response, training, maintenance, and spare-part supply.

Faster logistics and inventory availability within the Benelux market.

Customized welding process consulting, helping manufacturers achieve higher productivity, improved weld quality, and reduced operational costs.

Strong after-sales commitment, backed by Megmeet’s global technical resources and BUS’s regional expertise.

III. Industries Megmeet–BUS Serve Together

Through this partnership, Megmeet and BUS jointly serve a broad range of industrial sectors:

Automotive & Transportation: Robotic welding systems for body frames, chassis components, and battery enclosures.

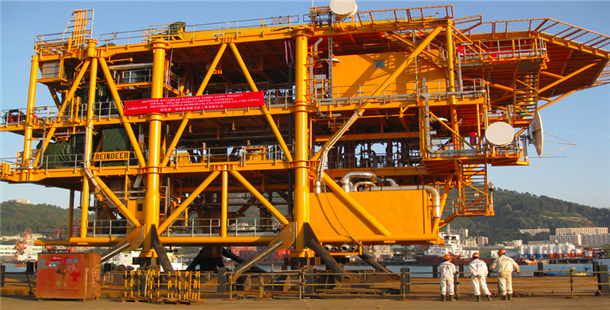

Shipbuilding & Offshore: Heavy-duty inverter power sources for hull construction, pipe welding, and deck fabrication.

Steel Structure & Construction: MIG/MAG and flux-cored arc welding for bridges, cranes, and high-rise frameworks.

Pressure Vessel & Energy Industry: Precision-controlled SAW and TIG solutions for boilers, tanks, and pipelines.

General Metal Fabrication: Cost-effective inverter machines for workshops, manufacturing plants, and repair stations.

Each industry benefits from Megmeet’s advanced welding process algorithms, such as deep penetration arc control, spatter reduction technology, and adaptive arc sensing, combined with BUS’s reliable field support and process optimization service.

IV. Driving Welding Innovation and Sustainability

Both Megmeet and BUS share a forward-looking vision — to make industrial welding smarter, safer, and more sustainable.

Together, we focus on three core values:

Innovation: Continuous R&D investment in digital control, waveform optimization, and intelligent welding process technology.

Reliability: Durable, high-efficiency welding machines built for 24/7 industrial operation under harsh conditions.

Sustainability: Energy-saving inverter systems that reduce CO₂ emissions and operational costs.

Megmeet’s integration of IoT and data-driven process monitoring allows factories to track weld quality, machine status, and maintenance cycles in real time — a crucial step toward Industry 4.0 welding automation.

With BUS’s local engineering support, Dutch and Belgian customers can adopt these advanced systems confidently, backed by on-site service and technical expertise.

V. Customer Value and Support

Our customers benefit from:

One-stop welding solution provider – from equipment selection to full process integration.

Technical training and certification programs for welders and maintenance teams.

Quick turnaround for repairs and spare parts, ensuring maximum uptime.

Continuous process improvement support based on Megmeet’s global welding database and BUS’s field experience.

By combining Megmeet’s global innovation strength with BUS’s local service excellence, we ensure every customer receives professional guidance, reliable products, and measurable performance improvements.

VI. Contact Our Exclusive Partner - BUS – Industrial Tools

For inquiries, demonstrations, or technical support regarding Megmeet welding equipment in the Netherlands and Belgium, please contact:

BUS – Industrial Tools

Bohemenstraat 17 8028 SB Zwolle, Netherlands

📞 [Contact details as per BUS website]: www.bus.nl