I. Characteristics and Functions of Jacket Platforms

Offshore platforms are structures that provide production and living facilities for various marine activities such as drilling, oil extraction, transportation, observation, navigation, and construction. Based on their structural characteristics and operational states, offshore platforms can be categorized into three main types: fixed, mobile, and semi-mobile platforms.

Fixed platforms are directly supported and anchored to the seabed by piles, expanded base feet, or other structural components. Depending on their foundation type, fixed platforms are further divided into pile-based and gravity-based platforms. Mobile platforms float on water or rest on the seabed, capable of moving from one drilling site to another. They can be classified into two types based on their support: bottom-supported and floating platforms. Semi-mobile offshore platforms can be anchored in deep water while being mobile.

The jacket platform, also known as a pile platform, belongs to the fixed platform category. It is supported by a jacket structure embedded into the seabed, consisting of a lower jacket, steel piles, and an upper platform. These platforms are designed to withstand forces from wind, waves, and currents, making them highly adaptive, safe, reliable, structurally simple, and cost-effective. The jacket itself mainly comprises hollow leg columns and connecting bracing components.

II. Client Overview: Shenzhen Chiwan Shengbaowang Engineering Co., Ltd.

Shenzhen Chiwan Shengbaowang Engineering Co., Ltd. (CSE) is a joint venture company involving three shareholders: China National Offshore Oil Corporation (holding 36% of the shares), Shengbaowang Engineering Holdings Private Limited (holding 32% of the shares), and Shenzhen Xinnanshan Holdings Group Co., Ltd. (holding 32% of the shares). The company is located on the eastern shore of Chiwan Port in Shenzhen, occupying a production area of 185,000 square meters and a dock line of 406 meters. This facility can construct large offshore oil and gas jackets, platforms, and other structures on land. CSE is known for its efficient, reliable, and low-cost jacket manufacturing services.

P1 Jacket Structure

III. Welding Challenges at Jacket Platforms

Manufacturing jackets involves several challenging welding processes; one of the most complex is the saddle weld joint of the braces. This type of work is typically performed at high altitudes, where precision is paramount, positioning is often limited, and alignment suffers. To address these challenges involves using welding rods for the grounding layers, along with gas-shielded flux-cored wire for filling, often requiring multiple layers and large fill volumes. The following issues have persistently troubled the client on-site:

High-altitude Work: Welding is conducted from heights of 70 to 100 meters, leading to significant pressure loss and strong interference, which destabilizes the welding process, posing severe quality risks.

Equipment Redundancy: Due to the necessity of alternating between manual and gas-shielded welding processes, two welding machines are required on-site, leading to inefficient utilization and increased operational complexity.

Adverse Outdoor Conditions: The outdoor work environment is challenging, with large fill volumes requiring high current sustained welding, resulting in frequent equipment malfunctions and breakdowns.

Remote Control Limitations: The wire feeder offers only coarse adjustments for welding parameters without precise displays, negatively affecting overall welding quality.

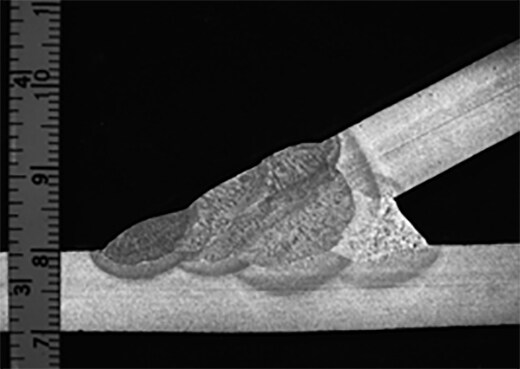

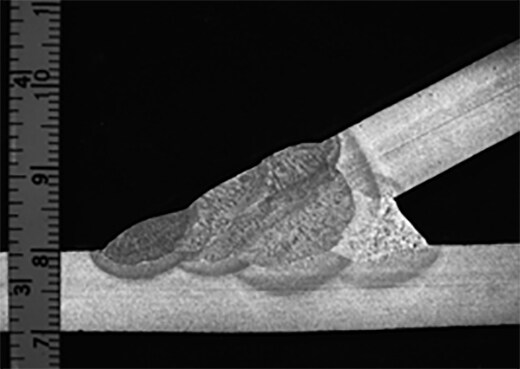

P2 Saddle Weld Process

P3 Saddle Weld Joint

IV. Features and Advantages of the Artsen CM500C Welding Machine

In light of the specific challenges faced by the client, we recommend the Megmeet Artsen CM500C welding machine. This machine is a fully digital industrial heavy-duty CO2/MAG/MMA intelligent inverter welder, designed specifically for the offshore engineering, shipbuilding, and steel structure industries, with the following advantages that address customer challenges:

High Protection Rating: The machine is built to withstand outdoor construction environments with high levels of vibration, impact, moisture, and salt spray.

Dual-direction Digital High-speed Carrier Communication Technology: As the first in the industry, this technology provides enhanced anti-interference capabilities, ensuring stable and reliable parameters over 100 meters of remote welding.

Designed for High Duty Cycle: With a loading capacity of 100% at 500A, the machine can maintain stable welding under long durations of high current.

Integrated Welding Parameter Display: The wire feeder is equipped with a parameter display, enabling welders to make precise adjustments. Supervisors can monitor settings more confidently.

Multi-functional Welding Machine: This device combines stick and gas-shielded capabilities, allowing workers to switch easily between welding processes with just one machine.

Fully Digital Design: Processes are controlled through software with a built-in expert database, concentrating arc energy for deeper penetration.

V. Welding Effectiveness Comparison

After using the Megmeet Artsen CM500C inverter welders, the comparative analysis revealed the following improvements:

Stable and Reliable High Current Welding: The remote wire feeder's parameter display significantly enhanced welding quality, reducing the repair rate by 15%.

Single Machine Efficiency Boost: The capability of one welding machine to meet both manual and gas-shielded welding needs improved equipment utilization by 30%.

Significant Decrease in Equipment Failures: The failure rate of the welding machine dropped dramatically, with repair needs reduced by 50%.

Improved Penetration Depth: The deep penetration and multi-layer welding techniques minimized the risk of incomplete joints, thereby ensuring welding quality.

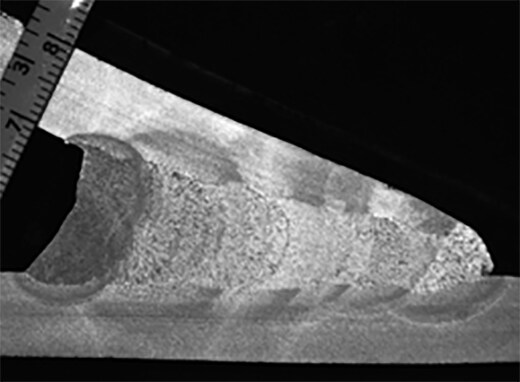

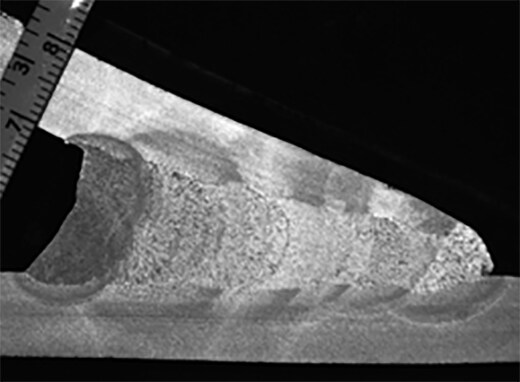

P4 Macroscopic View of Weld Penetration

P5 Macroscopic View of Weld Penetration

VI. Application of the Artsen CM500C Welding Machine

The Artsen CM500C welding machine has been effectively employed in various challenging conditions. Below are images showcasing real-world applications of this equipment in welding scenarios encountered by Shenzhen Chiwan Shengbaowang Engineering Co., Ltd.

P6 On-Site Welding Conditions

P7 Wet Weather Welding Conditions

The versatility and advanced features of the Artsen CM500C have made it an essential tool in the operational workflow. The effectiveness of this machine was particularly highlighted during rainy conditions, where traditional welding machines would typically struggle. The high protection rating and robust design allowed consistent performance, ensuring that project timelines were adhered to even under less-than-ideal weather circumstances.

VII. Conclusion

In conclusion, the adoption of the Megmeet Artsen CM500C welding machine represents a strategic investment for Shenzhen Chiwan Shengbaowang Engineering Co., Ltd. By addressing the specific challenges of offshore construction, this machine not only enhances welding quality and efficiency but also contributes to overall project success. As the industry evolves, having reliable, advanced equipment will be critical in meeting the demanding requirements of modern offshore engineering projects.