I. Products - Aluminum windows and door frameworks

Aluminum windows and door frameworks are made of extruded aluminum profiles of various shapes. It's widely used in construction and decoration. Huge numbers working in manufacturing are located in the major cities in Southern and Central China.

Aluminum Doors

Aluminum Windows

II. Welding Technical Challenges

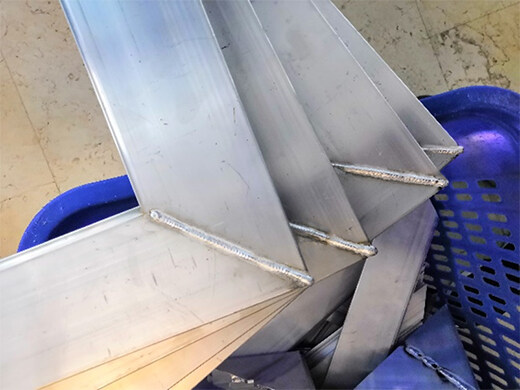

Riveting used to be the major method of joining aluminum windows and doors. But a gap will appear at the joint points after long-time usage. The appearance is damaged. Leaking will also happen so that wind and water will go thru. Heat preservation would also turn ineffective. The following challenges also exist for arc welding.

1)Burn-thru happens frequently because the thickness is only 1.0-1.5mm;

2)Gas pore is often found inside the seam for the sections with low welding amperage.

3)Inadequate fusion on both sides of the workpiece. Low intensity.

4)Low welding speed and production efficiency.

5) Heavy workload of grinding because of welding spatter. Welding appearance is therefore influenced.

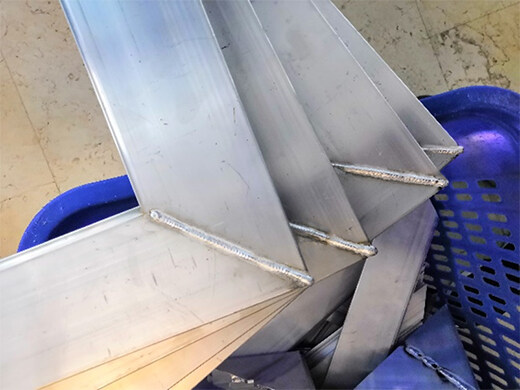

Defects Resulted from Welding Quality

III. MEGMEET Welding Equipment and Solutions

Dex PM3000 Series MIG/MAG welding machine was recommended with a pulse process for aluminum. As an inverter welding equipment with full digital control, Dex PM3000 is capable of welding carbon steel and stainless steel with synergic and pulse MIG/MAG, and aluminum with pulse MIG process. It is featured with the following strong points.

1)Smooth in arc ignition, stable and consistent in the welding arc, and low in welding spatter.

2)Fast in arc ignition and crater. Centralized in arc energy, which brings better penetration depth and welding speed.

3)Expert data on aluminum welding is available. Parameters of different sections of the welding process are also open for adjustment to meet the demands of on-site conditions and to ensure welding quality.

4)Wire-feeder is equipped with a high-performance motor, coded wheel, feedback mechanism, and four-roller structure. Precise and stable wire-feeding is ensured for high-quality welding.

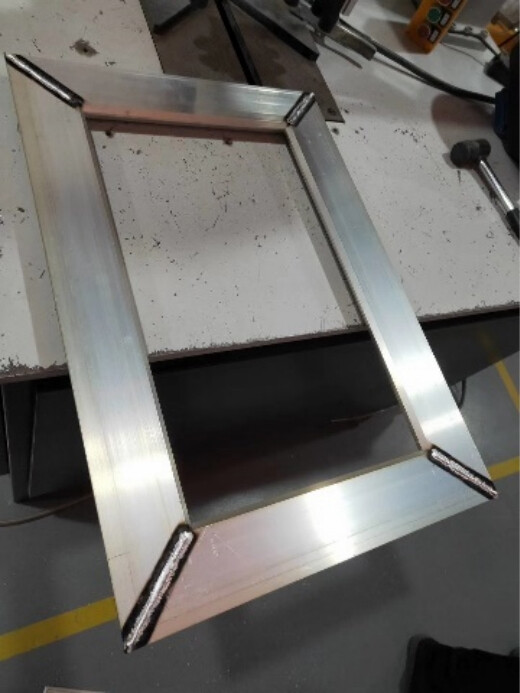

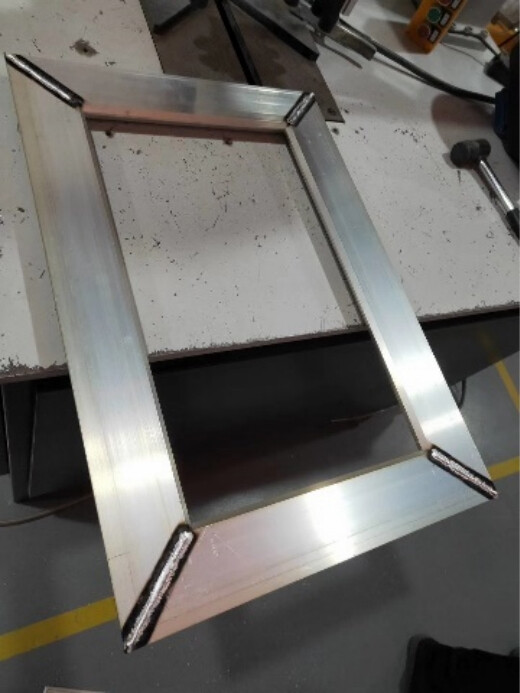

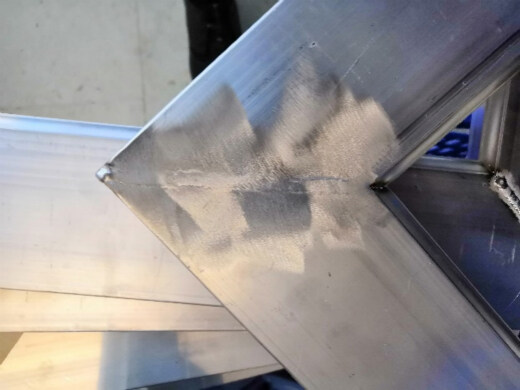

Workpiece

Welding Results

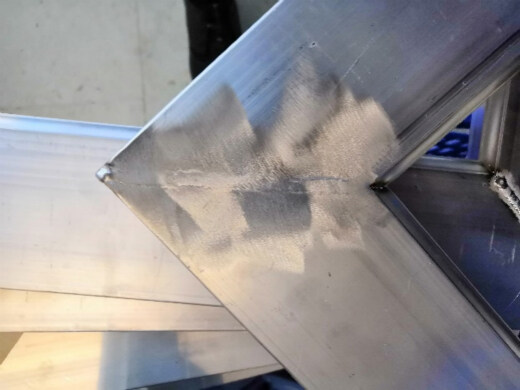

After-welding Grinding

IV. Comparison of Welding Result

Dex PM3000 was installed with a robotic welding station. Production efficiency has been greatly increased. Welding speed went up to 0.6m/min. The welding result turned out to be uniform and bright with well-controlled finishing. Defectives of gas pore and undercut did not happen. The welding spatter was extremely low. The first-time yield rate has reached 98%.

V. Application of Dex PM3000 Series MIG/MAG welders

Robotic Welding Station on Site