On December 23, 2022, the award ceremony of the National Industrial Internet APP and Information Consumption Race themed “Gather new kinetic energy, and create new economy with digitization” was held in Zhuzhou, Hunan. The race was initiated by MIIT, co-sponsored by Ministry of Industry and Information Technology and the People's Government of Hunan Province, co-organized by China Center for Information Industry Development, Department of Industry and Information Technology of Hunan Province, and the People's Government of Zhuzhou, and co-executed by China Information Weekly, Zhuzhou Bureau of Industry and Information Technology, Administrative Committee of Zhuzhou Economic Development Zone, China-Germany intelligent manufacturing alliance, China Big Data Enterprise Alliance and China Software Park Development Alliance. It is a professional event with the highest level and widest coverage in the field of industrial Internet APP and information consumption, known as“Oscar” in the field of industrial Internet APP and information consumption.

This race attracted nearly 2,500 teams across China to participate. Megmeet created a set of professional“SMARC Welding Information Management Systems”, which deeply integrated industrial Internet technology and welding application technology. After four months of layers of screening, it finally stood out from 240 projects, topped the list, and won "2022 Industrial APP Digital Manufacturing and Management Reward".

In addition to the prize money, the winning projects will also be recommended to be selected as industrial Internet App excellent solutions, new information consumption pilot demonstration projects, and given priority to be selected as "National Industrial Internet APP and Information Consumption Race Top 100 Industrial APP Project Collection" and "National Industrial Internet APP and Information Consumption Race Top 100 Information Consumption Project Collection" and get special fund support and other incentives.

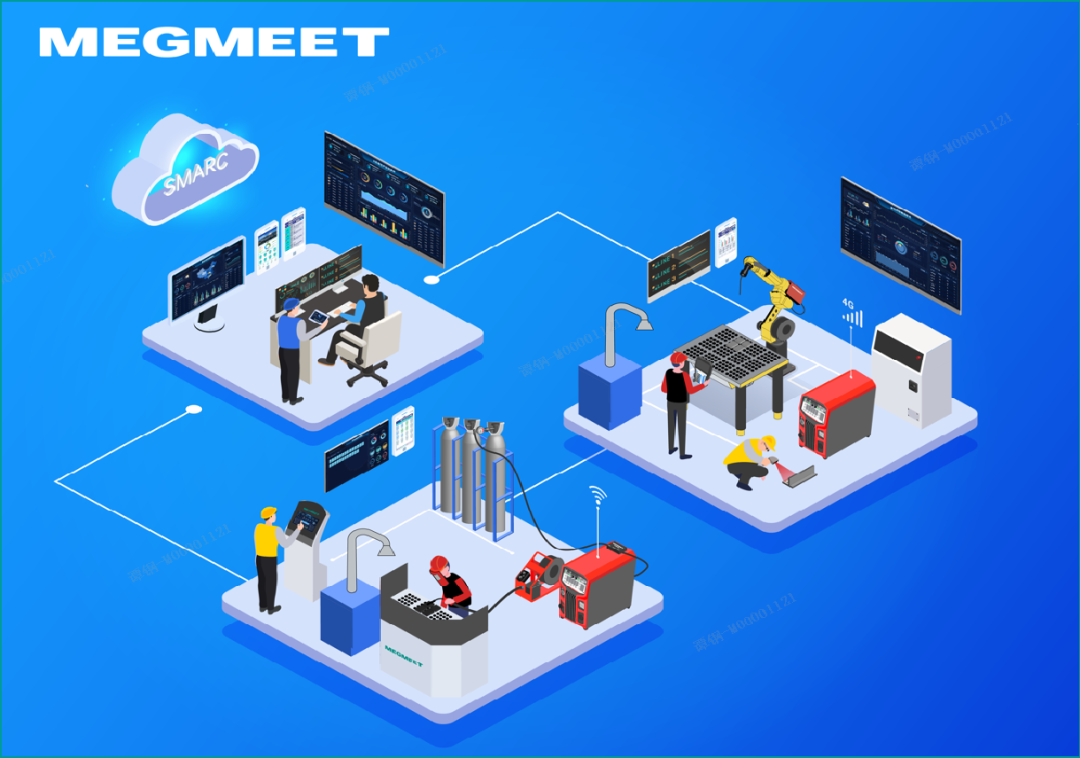

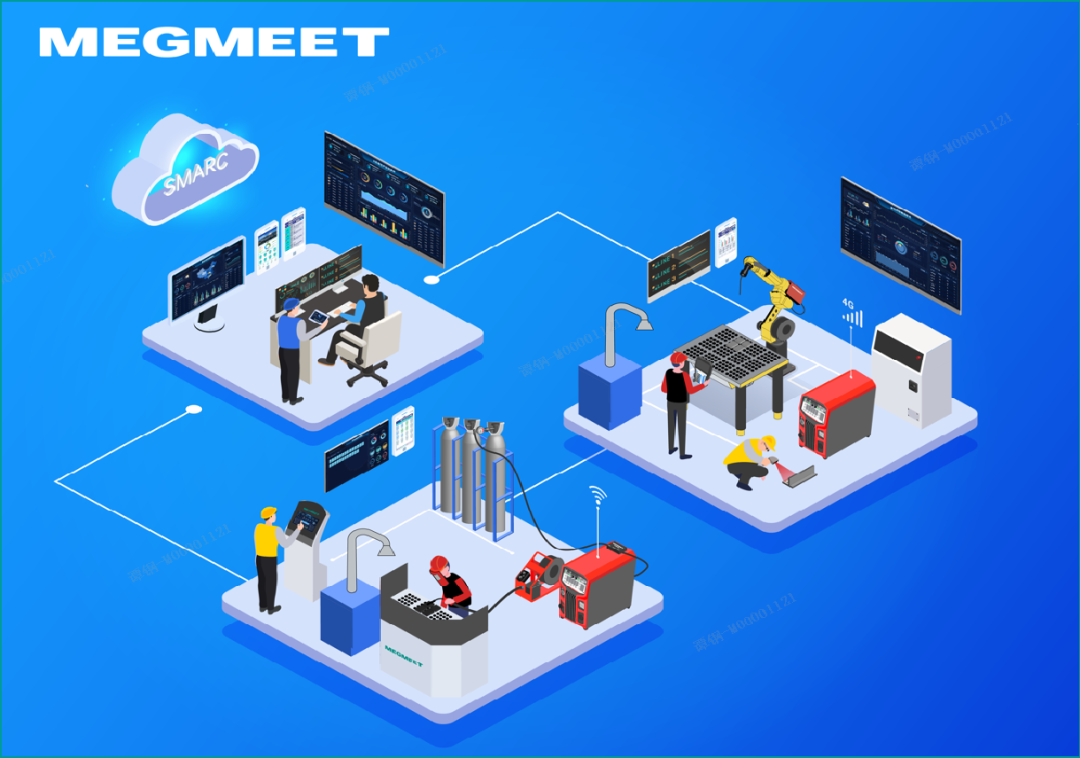

Megmeet “SMARC Welding Information Management System” is mainly used in the digital management of welding production. On the one hand, the system collects the welding production data of welding equipment and welders through IOT equipment, achieving real-time monitoring of welding production data, data storage, and statistical analysis. At the same time, the production manager can conduct real-time monitoring of the welding production through the WEB of the system or the app Mobile Phone, and remotely send operation instructions and operation parameters to the welding equipment on the WEB of the system or the APP of Mobile Phone for remote operation and parameters control of the welding equipment.

On the other hand, welders can bind or unbind the equipment through mobile phone apps, to achieve the recording and statistics of working hours and efficiency. At the same time, welders can scan bar codes, collect welding workpiece information for associated recording, record process parameters, and return weld seam information, to realize real-time recording and storage of the data during the welding process and quality traceability. In addition, the production manager can create production tasks in the system intelligently, and welders can receive welding tasks according to the actual situation, so as to achieve the assignment and management of welding tasks.

The launch of the SMARC Welding Information Management System aims to help users improve the efficiency and management level of welding production, reduce welding production costs, and improve welding production quality. The system provides users with refined welding data monitoring, multi-dimensional welding data analysis, and full-digital welding production management. It provides users with comprehensive solutions in the welding production and manufacturing process from the aspects of human, machine, materials, methods, environment, and currents, and provides platforms and services for the digital transformation and the integration of IT application and industrialization of welding manufacturing enterprises.

At present, Megmeet SMARC Welding Information Management System has been applied worldwide, with more than 15,000 networking welding machines, increasing the sales of welding equipment and IOT solutions by more than 200 million. Megmeet forms deep cooperation with over 100 major customers in the industry, making great contributions to the value-added sales and strategic development of welding products.

Megmeet has been taking industrial thinking as the core, lean production as the guide, cost reduction and efficiency as the starting point, to further improve the welding quality and improve welding efficiency, and the ability to meet mass commercial applications as the evaluation criteria. Through continuous technological innovation and intelligent manufacturing upgrading, Megmeet deep digging techniques innovate products, and strengthen platform construction, under the double guidance of market + brand, strives to build a "stable, accurate and refined" strong Chinese high-end brand, provide customers with more efficient, more reliable, more energy saving and more intelligent welding machine products, help partners effectively break the current Internet of things application bottleneck, better break the monopoly of foreign brands, realize the domestic replacement of imports, ensure national security, and provide important support for the confidentiality of Chinese engineering application data.

Related articles:

1. Megmeet Brand-new SMARC Intelligent Welding Cloud System

2. 2022 Industrial APP Digital Manufacturing & Management Reward