Pulse welding machines have revolutionized the industry, offering superior quality and efficiency, especially for automated processes. However, ask any manual welder, and you'll often hear a different story. Traditional pulse welding has presented significant challenges for those on the front lines – slower speeds, high consumable costs, complex settings, and a less-than-friendly arc. These drawbacks have often made pulse welding a frustration rather than an advantage for manual applications.

At Megmeet Welding Technology, we listened. We understood the daily struggles faced by manual welders, and we re-engineered pulse welding from the ground up to meet your needs. Introducing the Megmeet DEX 2 "Quick Pulse" welding machine – a breakthrough designed to bring the benefits of pulse welding directly to your hands, without the typical headaches.

The Manual Welder's Dilemma with Traditional Pulse Welding:

Here's why traditional pulse welding hasn't been ideal for manual applications:

Slower Speeds: Compared with conventional direct current welding machines (DC welding machines), the welding speed of pulse welding machines is more than 30% slower, and this disadvantage is particularly obvious in “piecework” occasions.

High Consumable Costs: Increased torch heating, high hot/cold alternation, and short accessory lifespan mean frequent replacements and higher costs.

Complex Setup: Picky gas ratios, high sensitivity to dry extension, and intricate parameter adjustments demand expert-level technique and experience.

Challenging Arc Characteristics: Long arcs, difficulty controlling weld formation, increased porosity and undercut risks, loud arc noise, and strong radiation make for a less comfortable and less effective welding experience.

Compared with conventional pulse welding machines, the advantages of “Quick Pulse” are:

The Megmeet DEX 2 "Quick Pulse" directly addresses these pain points, offering distinct advantages that put the manual welder first:

The Best of Both Worlds: "Quick Pulse" seamlessly blends the superior control of pulse welding with the familiar feel and speed of traditional DC welding. It's pulse welding that finally feels right for manual operation.

Significant Speed Boost: Experience over 20% faster welding speeds compared to conventional pulse machines, helping you boost productivity and output.

Simplified Operation, Superior Results:

▲ Higher Tolerance: More forgiving with mixed gas ratios and better adaptability to dry extension.

▲ Improved Arc Control: A lower, more concentrated arc makes it easier to achieve optimal weld formation, significantly reducing undercut and other defects.

▲ User-Friendly Adjustment: Simplified operation with synergistic and separate adjustment options, making parameter tuning intuitive even for complex welds.

Deeper Penetration, Stronger Roots: The lower, more concentrated arc delivers deeper penetration and stronger penetrability, making it ideal for inner groove welding of medium and thick plates and greatly enhancing root fusion quality.

Reduced Costs, Increased Comfort:

▲ Extended Consumable Life: Lower arc voltage and reduced thermal radiation significantly extend the lifespan of welding torches and accessories, cutting down on replacement costs.

▲ Improved Welder Comfort: Reduced thermal radiation and less arc noise create a more comfortable and safer working environment.

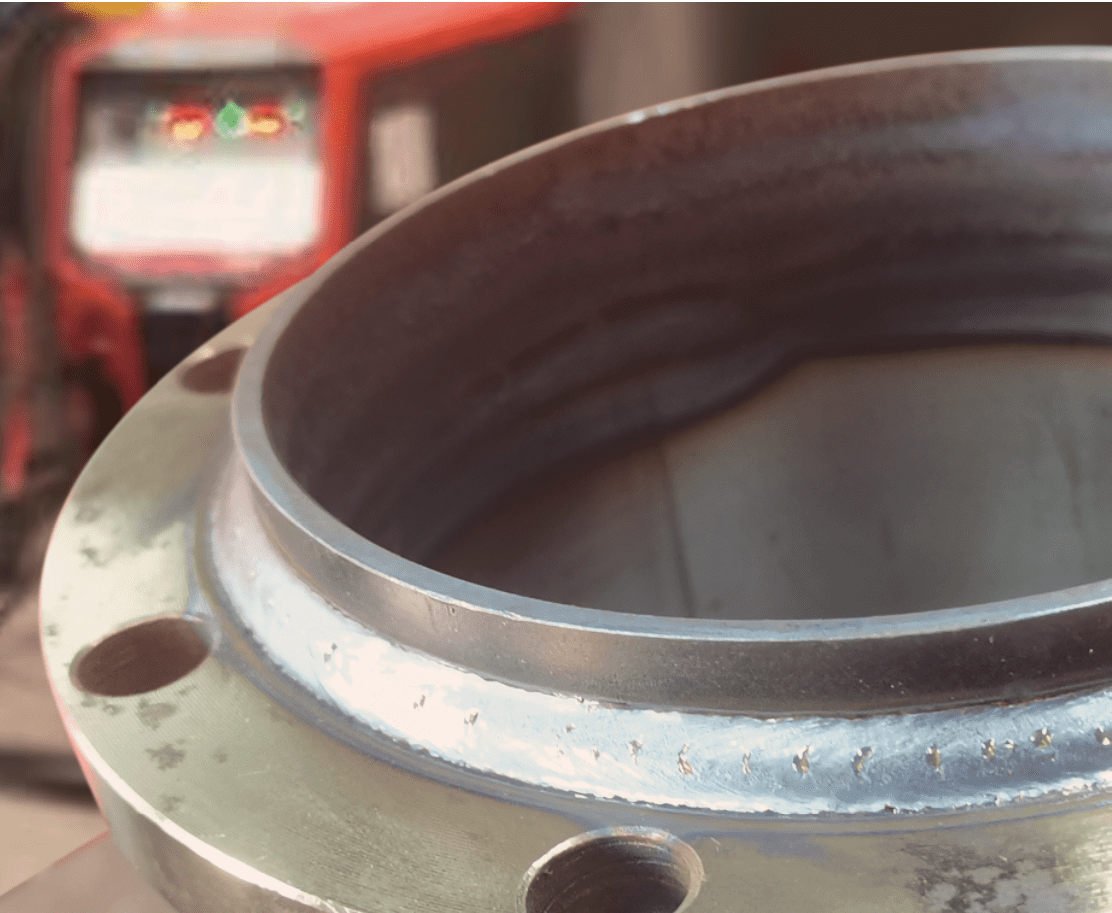

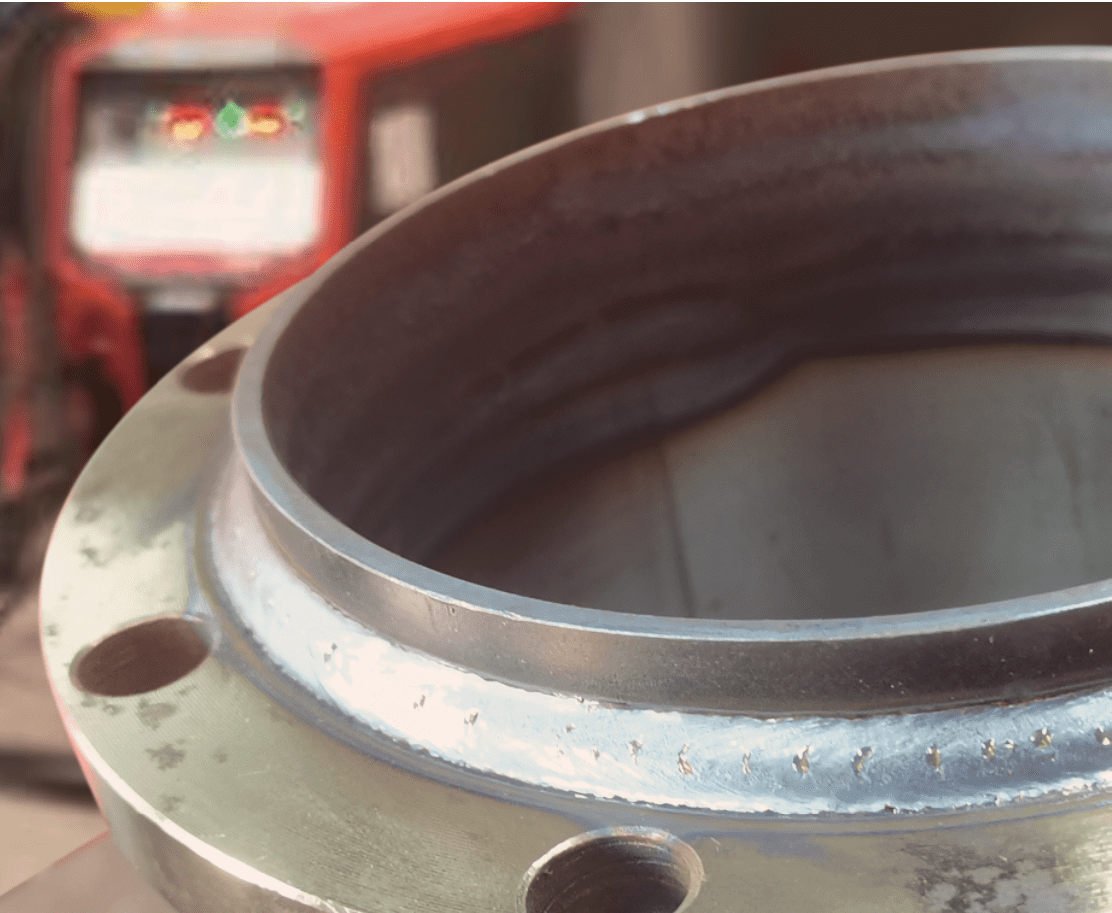

Welding Effects of Megmeet DEX 2 "Quick Pulse":

See "Quick Pulse" in Action!

Witness the revolutionary performance of the Megmeet DEX 2 "Quick Pulse" firsthand. We will have a dedicated booth showcasing live demonstrations at Schweißen & Schneiden 2023 in ESSEN.

Don't just take our word for it – come experience the difference "Quick Pulse" can make for your manual welding needs!

Related articles:

1. Pulse Technology’s Role in Enhancing Efficiency and Precision

2. Pulsed Welding Technology: Solution to Sheet Metal Burn-Through

3. Pulse Function of Welders & Pros and Cons of Pulse Welding

4. Why Choose a Pulse Welding Machine: Insights from Experts

5. Testimony of Excellence: MEGMEET DEX PM3000 Pulse Welding Machine Review