The Product

The product to weld was an electric radiator. Being easy to move around, it is an effective supplement when and where concentrated heating is not available. Oil is used inside the radiator instead of water to conduct heat. Penetration on the back side is requested after welding on the front, so that a totally enclosed space will be created, not allowing any leaking.

Electric Radiator

The Customer

1)The Midea Group is a world-class technology giant in consumer electronics, HVAC, industrial robots and automation, intelligent supply chain (logistics), etc. It was ranked 323 in the Fortune 500 in 2018. The sales revenue reached US$35.7 billion in 2017, providing direct jobs to over 100,000 people worldwide.

2)Midea’s diversified products and services range from kitchen appliances to refrigerators, washing machines, and various home appliances. The HVAC includes household and central air conditioners, heating, and ventilation systems. After the acquisition of KUKA Robotics and joint ventures with YASKAWA Robot, Midea enters the industrial robot and automation business.

3)The Midea electric radiators are featured as high in energy efficiency and comfortable for users. While holding a high market position in China, Midea occupied 44.56% of the retailing market and 22.97% of the online sales in 2018. Both were NO.1 in the competition.

The Technical Challenge

1)Under the same power grind of the heat radiator, welding machines work side by side with shearing and punching machines, both are super big in power consumption. Once they start and stop, the surge in input power will bring a remarkable change in welding arc energy. It causes easily incomplete penetration and burn-through. Even with a voltage stabilizer, the influence of power line fluctuation can’t be avoided.

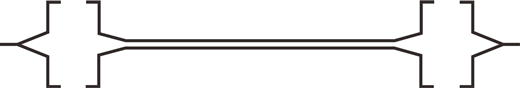

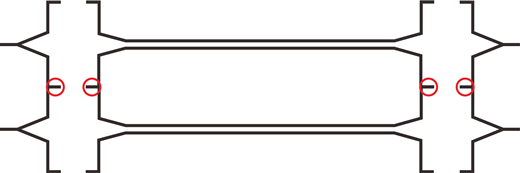

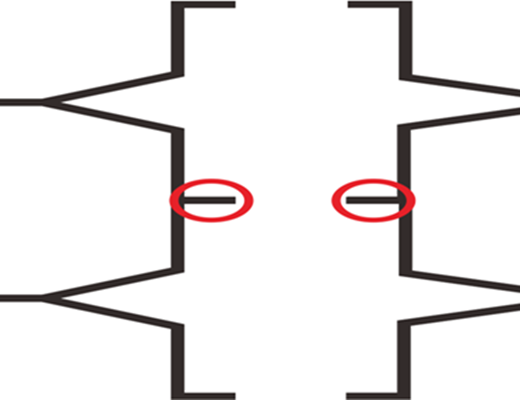

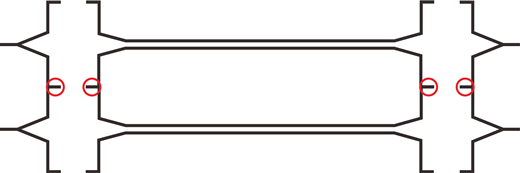

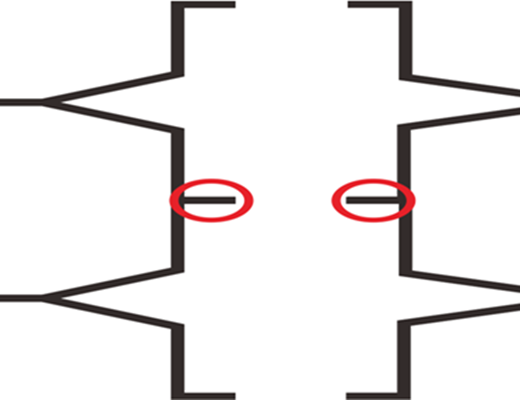

2)The metal thickness is 0.5mm. After being punched into sheets, they will be welded side by side to form tubes, which then will be welded up and make a whole set of radiators. The red cycles in the following pictures show the key joints. It can be considered as overlapping welding of 2 O-shape metal 0.5 in thickness and 8mm in width. Welding with suitable and stabilized current is crucial to success. On the one hand, penetration on the backside must be granted by welding on the front side to form an enclosed space. On the other hand, burn-through and consequential leaking will not be allowed.

3)Both oil stains and rusty surfaces are quite common for sheet metal. It resulted in a defective rate as high as 25% after the one-time welding, mainly because the present conventional welders are not able to output stably as the arc energy goes up and down.

<img src="http://www.megmeet-welding.com/uploadfiles/2020/07/20200720180002308.png" title="Sheet Metal after Stamping" alt="Sheet Metal after Stamping/>

Sheet Metal after Stamping

Pairing before Welding

Welding Positions

Welding Positions

Leakage Test after Welding

MEGMEET Equipment and Solutions

Megmeet supplied the Artsen plus350D series welding machines with full digital control for heavy-duty applications. Artsen plus350D series welding machines were recommended with a synergic MAG welding process to work with 50-60A and 0.8mm solid wire.

1)Unlike conventional welding machines, the Artsen plus350D series welding machines adapt the power topology of the full-digital and high-frequency inverters. Together with the HF and full-digital control algorithm of DSP (digital signal processing), the Artsen plus350D series welding machines take a real-time sampling of input voltage, voltage after rectification, output voltage, and current. At the frequency of 64KHZ, each PWM output would be alternated according to the working situation and the welding status and ensure the stabilization of the whole welding process. Within ±25% of AC380V, the arc status won’t change with the fluctuation of the power line. The Artsen plus350D series welding machines are also capable of working within the same power grind of large-power equipment. The cost of a power stabilizer is also saved.

2)The Artsen plus350D series welding machines are concentrated and stable in the welding arc, and strong in direction. Facing the various seam situations, it can adjust immediately through software to ensure the consistency of the welding arc. With the confidence to handle problems like oil stain, rust, and low-quality cutting.

Comparison of Welding Result

Artsen plus350D series welding machines helped Midea to raise the yield rate of one-time processing up to 98%. Time and labor cost for 2nd time welding is largely saved. Production efficiency is remarkably increased.

The Production Line

Workpiece

The Application

Artsen Plus on-Site