Stock Code

002851

- Home

- About

-

Products

- Selection table

- Artsen CM500C MIG/MAG Welders

- Artsen II P(C)M Double-pulse MIG/MAG Welders

- Artsen Plus D/P/Q MIG/MAG Welders 350/400/500A

- Artsen Pro Series MIG/MAG Welding Machine

- Dex DM/PM MIG Welders 3000A

- Dex2 L Series MIG Welding Machine

- Dex2 M Series MIG Welding Machine

- Dex2 Ultra Series AC-MIG Welding Machine

- Ehave CM MIG/MAG Welders 350/400/500A

- Ehave-2 CM Multi-process Welders

- MetaTIG ACDC HF TIG Welders 315/400/500A

- MetaTIG DC HF TIG Welders 315/400/500A

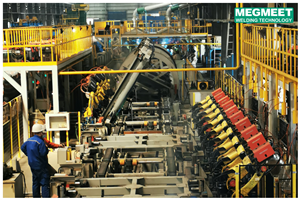

- Robotic and Automatic Welding

- Ray & Lux Laser Welders (1.5KW/2KW/3KW)

- SMARC Intelligent Welding System

- Solutions

- Data download

- Contacts